Abstract

Multiaxial fatigue life analysis of notched specimens is a critical issue for structural integrity design. However, there is still a lack of multiaxial fatigue life prediction models with coupled notch effect and probability distributions, which are vital for the fatigue design of key components. Therefore, in this study, a new probabilistic fatigue life prediction model is proposed for notched specimens in structural integrity design, which combines the three-parameter Weibull distribution (TPWD) with the effective strain energy density (ESED) to estimate the fatigue life of notched specimens with different survival probabilities. Meanwhile, the study involves the numerical calculation of the critical plane, extraction of the stress–strain distribution, calculation of strain energy density (SED), determination of critical damage region (CDR), and introduction of a weight function to quantify the damage weights of stress–strain at different locations around the notch on the effective damage parameters of the notch. The proposed model and three other energy-based models are validated using experimental data from notched specimens of Al7050, GH4196 alloys and medium steel En8, and the comparison results exhibit that the proposed model yields higher accuracy than three other models within the ± 3 life factor. Meanwhile, P-Weff-Nf curves of notched specimens with different survival probabilities are presented and analyzed under multiaxial loading. Overall, the proposed approach provides a new way to estimate the fatigue life of notched specimens, which can be useful for the fatigue design of key components.

Similar content being viewed by others

Abbreviations

- TPWD:

-

Three-parameter Weibull distribution

- ESED:

-

Effective strain energy density

- SED:

-

Strain energy density

- CDR:

-

Critical damage region

- HSV:

-

High stress volume

- TCD:

-

Theory of critical distances

- HCF:

-

High cycle fatigue

- LCF:

-

Low cycle fatigue

- \(\varepsilon^{\prime}_{xy}, \varepsilon^{\prime}_{xz}\) :

-

Shear strains after coordinate transformation

- \(\varepsilon^{\prime}_{xx}\) :

-

Normal strain after conversion

- n%:

-

Experience parameter to determine the HSV range

- \(\sigma_{n}\) :

-

Lower stress limit of HSV

- \(A^{\prime } ,r^{\prime }\) :

-

Material constants

- W c :

-

Plastic work per cycle per unit volume

- \(\varepsilon_{p}\) :

-

Plastic normal strain

- \(\gamma_{p}\) :

-

Plastic shear strain

- \(\sigma\) :

-

Normal stress

- \(\tau\) :

-

Shear stress

- \(\Delta W_{t}\) :

-

Total cyclic SED

- \(k_{0}, \alpha, C\) :

-

Material constants

- \(W^{*}\) :

-

SED at any point

- W max :

-

Maximum local SED

- W n :

-

Lower limit of SED in the effective region

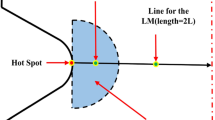

- L LM :

-

Critical distance

- W(r):

-

Energy density function

- \(\gamma\) :

-

Relative stress gradient

- r :

-

Radius from the notch root

- \(\sigma (r)\) :

-

Stress function

- Y w :

-

Strain energy gradient of the notched component

- \(S_{\sigma ,0.5} ,S_{\tau ,0.5}\) :

-

Area surrounded by normal stress and shear stress normalization curves

- \(\omega (r)\) :

-

Normalized curve expression

- p, q, z :

-

Material constants

- \(\varphi (r)\) :

-

Weight function

- \(\varphi^{\prime}(r)\) :

-

Modified weight function

- S :

-

Maximum stress

- N :

-

Number of fatigue cycles

- S 0 :

-

Maximum stress correction parameter

- N 0 :

-

Life correction parameter

- D:

-

Constant

- x :

-

Independent variable

- \(\alpha\) :

-

Position parameter

- \(\beta\) :

-

Scale parameter

- \(\gamma\) :

-

Shape parameter

- A, B :

-

Calibration parameters

- \(\mu^{\prime}\) :

-

Number of fatigue cycles

- W eff,i :

-

Effective strain energy density

- \(n^{\prime}\) :

-

Sample size

- N f,i :

-

Number of fatigue failure cycles corresponding to each effective strain energy density Weff,i

- N e :

-

Experimental life

- N p :

-

Predicted life

- E N :

-

Prediction error

- μ :

-

Mean value

- δ :

-

Standard deviation of EN

References

Hu Y, Wu S, Xie C et al (2021) Fatigue life evaluation of Ti–6Al–4V welded joints manufactured by electron beam melting [J]. Fatigue Fract Eng Mater Struct 44(8):2210–2221

Chen G, Zhang X, Xu DK et al (2017) Multiaxial ratcheting behavior of zirconium alloy tubes under combined cyclic axial load and internal pressure [J]. J Nucl Mater 489:99–108

Amjadi M, Fatemi A (2020) Multiaxial fatigue behavior of thermoplastics including mean stress and notch effects: experiments and modeling [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2020.105571

Zhu SP, Liu Q, Zhou J et al (2018) Fatigue reliability assessment of turbine discs under multi-source uncertainties [J]. Fatigue Fract Eng Mater Struct 41(6):1291–1305

Carpinteri A, Spagnoli A (2001) Multiaxial high-cycle fatigue criterion for hard metals [J]. Int J Fatigue 23(2):135–145

Song W, Liu X, Xu J et al (2021) Multiaxial low cycle fatigue of notched 10CrNi3MoV steel and its undermatched welds [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2021.106309

Liao D, Zhu SP (2019) Energy field intensity approach for notch fatigue analysis [J]. Int J Fatigue 127:190–202

Qi X, Liu T, Shi X et al (2021) A sectional critical plane model for multiaxial high-cycle fatigue life prediction [J]. Fatigue Fract Eng Mater Struct 44(3):689–704

Shamsaei N, Gladskyi M, Panasovskyi K et al (2010) Multiaxial fatigue of titanium including step loading and load path alteration and sequence effects [J]. Int J Fatigue 32(11):1862–1874

Glinka G, Shen G, Plumtree A (1995) A multiaxial fatigue strain energy density parameter related to the critical fracture plane [J]. Fatigue Fract Eng Mater Struct 18(1):37–46

Neuber H (1961) Theory of stress concentration for shear-strained prismatical bodies with arbitrary nonlinear stress-strain law[J]. J Appl Mech 28:544–549

Sharpe WN, Wang KC (1991) Evaluation of a modified monotonic neuber relation[J]. J Eng Mater Technol 113(1):1–8

Molski K, Glinka G (1981) A method of elastic-plastic stress and strain calculation at a notch root[J]. Mater Sci Eng 50(1):93–100

Moftakhar A (1995) Calculation of time-independent and time-dependent strains and stresses in notches [D]. University of Waterloo (Canada)

Ince A, Glinka G, Buczynski A (2014) Computational modeling of multiaxial elasto-plastic stress–strain response for notched components under non-proportional loading[J]. Int J Fatigue 62:42–52

Taylor D (1999) Geometrical effects in fatigue: a unifying theoreticalmodel[J]. Int J Fatigue 21(5):413–420

Susmel L (2008) The theory of critical distances: a review of its appli cations in fatigue [J]. Eng Fract Mech 75(7):1706–1724

Liao D, Zhu SP, Correia JAFO et al (2020) Recent advances on notch effects in metal fatigue: a review [J]. Fatigue Fract Eng Mater Struct 43(4):637–659

Wu YL, Zhu SP, He JC et al (2021) Assessment of notch fatigue and size effect using stress field intensity approach [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2021.106279

Ye WL, Zhu SP, Niu XP et al (2021) Fatigue life prediction of notched components under size effect using stress gradient- based approach [J]. Int J Fract. https://doi.org/10.1007/s10704-021-00580-5

Garrido A, Caro-Carretero R, Jimenez-Octavio JR et al (2019) A new approach to fitting the three-parameter Weibull distribution: An application to glass ceramics [J]. Commun Stat Theory Methods 50(14):3403–3420

Khalil A, Ijaz M, Ali K et al (2020) A novel flexible additive Weibull distribution with real-life applications [J]. Commun Stat Theory and Methods 50(7):1557–1572

Strzelecki P (2021) Determination of fatigue life for low probability of failure for different stress levels using 3-parameter Weibull distribution [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2020.106080

Park JP, Park C, Cho J et al (2017) Effects of cracking test conditions on estimation uncertainty for Weibull parameters considering time-dependent censoring interval [J]. Materials 10(1):1–26

Shang DG, Sun GQ, Jing D et al (2007) Multiaxial fatigue damage parameter and life prediction for medium-carbon steel based on the critical plane approach [J]. Int J Fatigue 29(12):2200–2207

Liu JH, Hua FL, Lang SS et al (2022) Evaluation of fatigue strength on multiaxial notched specimens considering failure probability [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2021.106649

He JC, Zhu SP, Liao D et al (2020) Probabilistic fatigue assessment of notched components under size effect using critical distance theory [J]. Eng Fracture Mech. https://doi.org/10.1016/j.engfracmech.2020.107150

Zhu SP, Ai Y, Liao D, et al (2021) Recent advances on size effect in metal fatigue under defects: a review [J]. Int J Fracture pp 1–23

Kuguel R (1961) A relation between theoretical stress concentration factor and fatigue notch factor deduced from the concept of highly stressed volume [J]. Soc Mater Sci 61:732–748

Sonsino CM, Moosbrugger E (2008) Fatigue design of highly loaded short-glass-fibre reinforced polyamide parts in engine compartments[J]. Int J Fatigue 30(7):1279–1288

Wang Y, Du W, Luo Y (2017) A mean plastic strain fatigue–creep life prediction and reliability analysis of AISI H13 based on energy method[J]. J Mater Res 32(22):4254–4262

Bandyopadhyay R, Prithivirajan V, Peralta AD et al (2020) Microstructure-sensitive critical plastic strain energy density criterion for fatigue life prediction across various loading regimes [J]. Proc Royal Soc A. https://doi.org/10.1098/rspa.2019.0766

Morrow J D (1964) Cyclic plastic starin energy and fatigue of metals[J]. Astm Stp

Garud Y (1981) A new approach to the evaluation of fatigue under multiaxial loadings[J]. J Eng Mater Technol 103(2):118–125

Ellyin F, Kujawski D (1984) Plastic strain energy in fatigue failure[J]. J Pressure Vessel Technol 106(4):342–347

Li XK, Zhu SP, Liao D et al (2022) Probabilistic fatigue modelling of metallic materials under notch and size effect using the weakest link theory [J]. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2022.106788

Lin CK, Lee WJ (1998) Effects of highly stressed volume on fatigue strength of austempered ductile irons [J]. Int J Fatigue 20(4):301–307

Qylafku G, Azari Z, Kadi N (1999) Application of a new model proposal for fatigue life prediction on notches and key-seats[J]. Int J Fatigue 21(8):753–760

Bo Z, Wang Y, Wei D et al (2017) Multiaxial fatigue life prediction for powder metallurgy superalloy FGH96 based on stress gradient effect[J]. Int J Fatigue 109:26–36

Caiza PDT, Ummenhofer T (2018) A probabilistic Stüssi function for modelling the SN curves and its application on specimens made of steel S355J2+ N [J]. Int J Fatigue 117:121–134

Cai W, Li W, Xu J (2022) Study on the PSN curve of sucker rod based on three-parameter Weibull distribution [J]. Materials. https://doi.org/10.3390/ma15020560

Liao D, Zhu SP, Qian G (2019) Multiaxial fatigue analysis of notched components using combined critical plane and critical distance approach [J]. Int J Mech Sci 160:38–50

Sun GQ, Shang DG (2010) Prediction of fatigue lifetime under multiaxial cyclic loading using finite element analysis [J]. Mater Des 31(1):126–133

Faruq NZ, Susmel L (2019) Proportional/nonproportional constant/variable amplitude multiaxial notch fatigue: cyclic plasticity, non-zero mean stresses, and critical distance/plane [J]. Fatigue Fract Eng Mater Struct 42(9):1849–1873

Chen X, Xu S, Huang D (2010) A critical plane-strain energy density criterion for multiaxial low-cycle fatigue life under non-proportional loading. Fatigue Fract Eng Mater Struct 22(8):679–686

Chu CC, Conle FA, Bonnen J (1993) Multiaxial stress-strain modeling and fatigue life prediction of SAE axle shafts In: McDowell D, Ellis J. Editors. Advances in Multiaxial Fatigue. West Conshohocken, PA: ASTM International, STP, 1191: 37–54.

Liu KC (1993) Method based on virtual strain-energy parameters for multiaxial fatigue life prediction. In: McDowell DL, Ellis R, editor. American Society for Testing and Materials STP 1191, Philadelphia, 1191: 67–84.

Gan L, Wu H, Zhong Z (2019) Use of an energy-based/critical plane model to assess fatigue life under low-cycle multiaxial cycles [J]. Fatigue Fract Eng Mater Struct 42(12):2694–2708

Acknowledgements

This research was supported by the National Natural Science Foundation of China, Grant/Award Number: 51605212; Natural Science Foundation of Gansu Province, Grant/Award Number: 20JR10RA161; Project of Hongliu Excellent Youth Program of Lanzhou University of Technology Grant/Award Number: 2020062001. Innovation Star Project for Outstanding Graduate Students of Gansu Province, Grant/Award Number: 2022CXZX-413; Innovation Star Project for Outstanding Graduate Students of Gansu Province, Grant/Award Number: 2022CXZX-417.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Andre T. Beck.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Wang, J., Wu, K. et al. Multiaxial notch fatigue probability modeling based on three-parameter Weibull distribution and effective strain energy density. J Braz. Soc. Mech. Sci. Eng. 45, 404 (2023). https://doi.org/10.1007/s40430-023-04312-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04312-9