Abstract

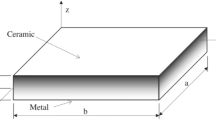

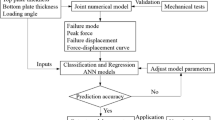

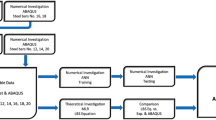

The principal purpose of the present investigation is to examine the ultimate shear strength (USS) of one-side corroded plates with cracks using the nonlinear finite element method (FEM). To this accomplishment, different geometrical parameters of crack position (CP), crack length (CL), pit depth (PD), pit diameter (PDM), pit position (PP), number of pits (NoP), and angle of crack (AoC), are investigated. Then, according to the provided numerical dataset, the USS of crack-pitted plates is estimated by designed artificial neural network (ANN). The numerical results indicate the highest significance of AoC (with a relative significance percentage of 21.44%) on the USS, while PDM (with a comparative significance percentage of 8.11%) has the lowest impression on the USS to shear yield strength ratio of considered plates. Moreover, the maximum mean square error (MSE) and the minimum correlation coefficient (R) of designed ANNs obtained 0.0077, and 0.8564, respectively. Also, an equation suggested estimating the USS of crack-pitted plates according to the weight and bias of designed ANNs.

Similar content being viewed by others

References

Alinia MM (2005) A study into optimization of stiffeners in plates subjected to shear loading. Thin-Walled Struct 43:845–860

Takami T, Ogawa H, Miyata T, Ando T, Tatsumi A, Hirakawa S, Tanaka Y, Fujikubo M et al. (2015) Study on buckling/ultimate strength of continuous stiffened panel under in-plane shear and thrust. In: The Twenty-Fifth International Ocean and Polar Engineering Conference

Glassman JD, Moreyra Garlock ME (2016) A compression model for ultimate postbuckling shear strength. Thin-Walled Struct 102:258–272

Bin S, Zhiqiang H, Jin W, Zhaolong Y (2016) An analytical method to assess the damage and predict the residual strength of a ship in a shoal grounding accident scenario. J Ocean Eng Sci 1(2):167–179

Sun L, Huang X (2022) Prediction of fatigue crack propagation lives based on machine learning and data-driven approach. J Ocean Eng Sci. https://doi.org/10.1016/j.joes.2022.06.041

ABS Corporate Technology (2012) Review of current practices of fracture repair procedures for ship structures

Brighenti R, Carpinteri A (2011) Buckling and fracture behaviour of cracked thin plates under shear loading. Mater Des 32:1347–1355

Brighenti R (2005) Buckling of cracked thin-plates under tension or compression. Thin-Walled Struct 43:209–224

Alinia MM, Hosseinzadeh SAA, Habashi HR (2007) Influence of central cracks on buckling and post-buckling behaviour of shear panels. Thin-Walled Struct 45:422–431

Wang F, Paik JK, Kim BJ, Cui W, Hayat T, Ahmad B (2015) Ultimate shear strength of intact and cracked stiffened panels. Thin-Walled Struct 88:48–57

Paik JK, Lee JM, Ko MJ (2004) Ultimate shear strength of plate elements with pit corrosion wastage. Thin-Walled Struct 42(8):1161–1176

Ahn JH, Kim IT, Kainuma S, Lee MJ (2013) Residual shear strength of steel plate girder due to web local corrosion. J Constr Steel Res 89:198–212

Dunbar TE, Pegg N, Taheri F, Jiang L (2004) A computational investigation of the effects of localized corrosion on plates and stiffened panels. Mar Struct 17:385–402

Jun M, Yoshiki T (2008) Research on retrofitting method for girder end with corrosion of the steel bridge. CAESAR, Civ Eng Res Rep

Sharifi Y, Paik JK (2011) Ultimate strength reliability analysis of corroded steel-box girder bridges. Thin-Walled Struct 49:157–166

Kim IT, Lee MJ, Ahn JH, Kainuma S (2013) Experimental evaluation of shear buckling behaviors and strength of locally corroded web. J Constr Steel Res 83:75–89

Zhao Z, Zhang N, Wu J, Gao Y, Sun Q (2020) Shear capacity of steel plates with random local corrosion. Constr Build Mater 239:117816

Kong Z, Yang F, Jin Y, Hong S, Wang X, Vu QV, Truong VH, Yu B, Kim SE (2021) Experimental study on bearing capacity of corroded high-strength bolt connections under shear force. Constr Build Mater 309:125117

Zhang Z, Ye J, Huang Z, Qin G, Xu S (2022) June. elastic buckling behavior of corroded uniformly compressed plates with three simply supported edges. Structures 40:946–959

Dwarakish GS, Nithyapriya B (2016) Application of soft computing techniques in coastal study–a review. J Ocean Eng Sci 1(4):247–255

Nowruzi H, Ghassemi H (2016) Using artificial neural network to predict velocity of sound in liquid water as a function of ambient temperature, electrical and magnetic fields. J Ocean Eng Sci 1:203–211

Mahmoodi K, Ghassemi H, Nowruzi H (2017) Data mining models to predict ocean wave energy flux in the absence of wave records. Zesz Nauk Akad Morskiej w Szczecinie. nr 49(121):119–129

Nowruzi H, Ghassemi H, Amini E, Sohrabi-asl I (2017) Prediction of impinging spray penetration and cone angle under different injection and ambient conditions by means of CFD and ANNs. J Braz Soc Mech Sci Eng 39:3863–3880

Nowruzi H, Ghassemi H, Ghiasi M (2017) Performance predicting of 2D and 3D submerged hydrofoils using CFD and ANNs. J Mar Sci Technol 22:710–733

Najafi A, Nowruzi H, Ghassemi H (2018) Performance prediction of hydrofoil- supported catamarans using experiment and ANNs. Appl Ocean Res 75:66–84

Ahmadi F, Ranji AR, Nowruzi H (2020) Ultimate strength prediction of corroded plates with center-longitudinal crack using FEM and ANN. Ocean Eng 206:107281

Nowruzi H (2022) Performance prediction of stepped planing hulls using experiment and ANNs. Ocean Eng 246:110660

Wei D, Zhang S (1999) Ultimate compressive strength prediction of stiffened panels by counterpropagation neural networks (CPN)

Pu Y, Mesbahi E (2006) Application of artificial neural networks to evaluation of ultimate strength of steel panels. Eng Struct 28:1190–1196

Cevik A, Guzelbey IH (2007) A soft computing based approach for the prediction of ultimate strength of metal plates in compression. Eng Struct 29:383–394

Ok D, Pu Y, Incecik A (2007) Artificial neural networks and their application to assessment of ultimate strength of plates with pitting corrosion. Ocean Eng 34:2222–2230

Fu B, Feng DC (2021) A machine learning-based time-dependent shear strength model for corroded reinforced concrete beams. J Build Eng 36:102118

Hosseinpour P, Hosseinpour M, Sharifi Y (2022) Artificial neural networks for predicting ultimate strength of steel plates with a single circular opening under axial compression. Ships and Offshore Struct 17(11):2454–2469

Kumar A, Arora HC, Kapoor NR, Kumar K, Hadzima-Nyarko M, Radu D (2023) Machine learning intelligence to assess the shear capacity of corroded reinforced concrete beams. Sci Rep 13(1):2857

Molland AF (2011) Ship structures. In: Molland AF (ed) The maritime engineering reference book: a guide to ship design, construction and operation. Elsevier, Oxford

Lu H, Dong P, Boppudi S (2015) Strength analysis of fillet welds under longitudinal and transverse shear conditions. Mar Struct 43:87–106

Zhang S, Kumar P, Rutherford SE (2008) Ultimate shear strength of plates and stiffened panels. Ships Offshore Struct 3:105–112

Daidola JC, Parente J, Rosenblatt Son M Orisamolu IR, Ma K (1997) Residual strength assessment of pitted plate panels. Sh Struct Comm Rep SSC-394

Hu Y, Cui W (2003) Residual ultimate strength of cracked plates and stiffened panels under combined loading. J Sh Mech 7:63–78

Karkalos NE, Efkolidis N, Kyratsis P, Markopoulos AP (2019) A comparative study between regression and neural networks for modeling Al6082-T6 alloy drilling. Machines 7(1):13

Rumelhart DE, Hinton GE, Williams RJ (1986) Learning internal representations by error propagation. In: Rumelhart DE, McClelland JL (eds) Parallel distributed processing. The MIT Press, Cambridge

Prechelt L (1998) Early stopping—but when? Springer, Berlin, pp 55–69

Choi B, Lee JH, Kim DH (2008) Solving local minima problem with large number of hidden nodes on two-layered feed-forward artificial neural networks. Neurocomputing 71(16–18):3640–3643

Trenn S (2008) Multilayer perceptrons: approximation order and necessary number of hidden units. IEEE Trans Neural Netw 19:836–844

Moriasi DN, Arnold JG, Van Liew MW, Bingner RL, Harmel RD, Veith TL (2007) Model evaluation guidelines for systematic quantification of accuracy in watershed simulations. Trans ASABE 50(3):885–900

Garson GD (1991) Interpreting neural-network connection weights. AI Expert 6:46–51

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Communicated by João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmadi, F., Nowruzi, H. & Rahbar-Ranji, A. Estimation of ultimate shear strength of one-side corroded-plates cracks by FEM and ANNs. J Braz. Soc. Mech. Sci. Eng. 45, 385 (2023). https://doi.org/10.1007/s40430-023-04300-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04300-z