Abstract

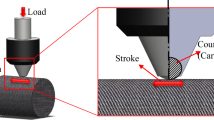

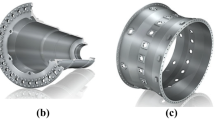

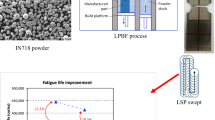

As with all additive manufacturing processes, selecting appropriate process parameters in the laser powder bed fusion (LPBF) process plays an important role in the surface integrity and mechanical behavior of Inconel 718 components. Hatch distance, laser power, laser scanning speed and layer thickness are the main parameters that can be altered in the LPBF process. This study focuses on the role of laser power and scanning speed when hatch distance is larger than laser spot size on product properties. This work reveals that LPBF process parameters significantly impact the fabricated Inconel 718 material properties. However, although the material properties are enhanced by selecting appropriate process parameters, the components need post-processing methods to have the desired properties. Heat treatment was applied as a post-process to obtain parts with the desired material properties. The effect of heat treatment applied to the parts fabricated at various laser power and laser scanning speeds on the parts’ surface integrity, and mechanical performance is comprehensively presented. Determining the details of the interactions of different production parameters with heat treatment is one of the motivations of this study. The presented results establish that heat treatment can change specimens’ microstructural aspects. The results also show a 10% increase in microhardness and a 14% increase in wear performance of specimens, due to the final state of the microstructure after heat treatment.

Similar content being viewed by others

References

Popovich AA, Sufiiarov VS, Polozov IA, Borisov EV (2015) Microstructure and mechanical properties of Inconel 718 produced by SLM and subsequent heat treatment. In: Key Engineering Materials. Trans Tech Publ. https://doi.org/10.4028/www.scientific.net/KEM.651-653.665

Jia Q, Gu D (2014) Selective laser melting additive manufacturing of Inconel 718 superalloy parts: densification microstructure and properties. J Alloys Compd 585:713–721. https://doi.org/10.1016/j.jallcom.2013.09.171

Lu Y, Wu S, Gan Y, Huang T, Yang C, Junjie L, Lin J (2015) Study on the microstructure mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt Laser Technol 75:197–206. https://doi.org/10.1016/j.optlastec.2015.07.009

Nguyen QB, Nai MLS, Zhu Z, Sun C-N, Wei J, Zhou W (2017) Characteristics of inconel powders for powder-bed additive manufacturing. Engineering 3(5):695–700. https://doi.org/10.1016/J.ENG.2017.05.012

Kumar P, Farah J, Akram J, Teng C, Ginn J, Misra M (2019) Influence of laser processing parameters on porosity in Inconel 718 during additive manufacturing. Int J Adv Manuf Technol 103(1):1497–1507. https://doi.org/10.1007/s00170-019-03655-9

Kulawik K, Buffat P, Kruk A, Wusatowska-Sarnek A, Czyrska-Filemonowicz A (2015) Imaging and characterization of γ′ and γ ″nanoparticles in Inconel 718 by EDX elemental mapping and FIB–SEM tomography. Mater Charact 100:74–80. https://doi.org/10.1016/j.matchar.2014.12.01

Popovich V, Borisov E, Popovich A, Sufiiarov VS, Masaylo D, Alzina L (2017) Impact of heat treatment on mechanical behaviour of Inconel 718 processed with tailored microstructure by selective laser melting. Mater Des 131:12–22. https://doi.org/10.1016/j.matdes.2017.05.065

Cai C, Zhou K (2022) Metal additive manufacturing. Digit Manuf. https://doi.org/10.1016/B978-0-323-95062-6.00005-X

Sanchez S, Smith P, Xu Z, Gaspard G, Hyde CJ, Wits WW, Ashcroft IA, Chen H, Clare A (2021) Powder bed fusion of nickel-based superalloys: a review. Int J Mach Tools Manuf 165:103729. https://doi.org/10.1016/j.ijmachtools.2021.103729

Ho I-T, Chang K-C, Tiparti D, Yeh A-C, Tin S (2021) Insight to agglomeration and chemical reactions of CoAl2O4 inoculants in IN718 processed by selective laser melting. J Alloys Compd 883:160753. https://doi.org/10.1016/j.jallcom.2021.160753

Dursun G, Ibekwe S, Li G, Mensah P, Joshi G, Jerro D (2020) Influence of laser processing parameters on the surface characteristics of 316L stainless steel manufactured by selective laser melting. Mater Today Proc 26:387–393. https://doi.org/10.1016/j.matpr.2019.12.061

Prashanth K, Scudino S, Maity T, Das J, Eckert J (2017) Is the energy density a reliable parameter for materials synthesis by selective laser melting. Mater Res Lett 5(6):386–390. https://doi.org/10.1080/21663831.2017.1299808

Sing SL, Wiria FE, Yeong WY (2018) Selective laser melting of titanium alloy with 50 wt% tantalum: effect of laser process parameters on part quality. Int J Refract Met Hard Mater 77:120–127. https://doi.org/10.1016/j.ijrmhm.2018.08.006

Choi J-P, Shin G-H, Yang S, Yang D-Y, Lee J-S, Brochu M, Yu J-H (2017) Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol 310:60–66. https://doi.org/10.1016/j.powtec.2017.01.030

Greco S, Gutzeit K, Hotz H, Kirsch B, Aurich JC (2020) Selective laser melting (SLM) of AISI 316L—impact of laser power layer thickness and hatch spacing on roughness density and microhardness at constant input energy density. Int J Adv Manuf Technol 108(5):1551–1562. https://doi.org/10.1007/s00170-020-05510-8

Wan H, Zhou Z, Li C, Chen G, Zhang G (2019) Effect of scanning strategy on mechanical properties of selective laser melted Inconel 718. Mater Sci Eng A 753:42–48. https://doi.org/10.1016/j.msea.2019.03.007

Mirkoohi E, Sievers DE, Garmestani H, Chiang K, Liang SY (2019) Three-dimensional semi-elliptical modeling of melt pool geometry considering hatch spacing and time spacing in metal additive manufacturing. J Manuf Processes 45:532–543. https://doi.org/10.1016/j.jmapro.2019.07.028

Bean GE, Witkin DB, McLouth TD, Patel DN, Zaldivar RJ (2018) Effect of laser focus shift on surface quality and density of Inconel 718 parts produced via selective laser melting. Addit Manuf 22:207–215. https://doi.org/10.1016/j.addma.2018.04.024

Guan K, Wang Z, Gao M, Li X, Zeng X (2013) Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater Des 50:581–586. https://doi.org/10.1016/j.matdes.2013.03.056

Koutiri I, Pessard E, Peyre P, Amlou O, De Terris T (2018) Influence of SLM process parameters on the surface finish porosity rate and fatigue behavior of as-built Inconel 625 parts. J Mater Process Technol 255:536–546. https://doi.org/10.1016/j.jmatprotec.2017.12.043

Chlebus E, Gruber K, Kuźnicka B, Kurzac J, Kurzynowski T (2015) Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater Sci Eng A 639:647–655. https://doi.org/10.1016/j.msea.2015.05.035

Kladovasilakis N, Charalampous P, Tsongas K, Kostavelis I, Tzovaras D, Tzetzis D (2022) Influence of selective laser melting additive manufacturing parameters in Inconel 718 superalloy. Mater 15(4):1362. https://doi.org/10.3390/ma15041362

Martínez S, Ortega N, Celentano D, Sánchez Egea AJ, Ukar E, Lamikiz A (2020) Analysis of the part distortions for Inconel 718 SLM: a case study on the NIST test artifact. Mater 13(22):5087. https://doi.org/10.3390/ma13225087

Anam MA, Pal D, Stucker B (2013) Modeling and experimental validation of nickel-based super alloy (Inconel 625) made using selective laser melting. In: International solid freeform fabrication symposium. Of Conference.: University of Texas at Austin. http://dx.doi.org/https://doi.org/10.26153/tsw/15570

Bourell D, Kruth JP, Leu M, Levy G, Rosen D, Beese AM, Clare A (2017) Materials for additive manufacturing. CIRP Ann 66(2):659–681. https://doi.org/10.1016/j.cirp.2017.05.009

Sunay N, Mert K, Kaynak Y (2020) Chemical post-processing methods for enhancing surface properties of parts fabricated by additive manufacturing: a review. Sigma J Eng Nat Sci 38(4):2027–2042

Atzeni E, Barletta M, Calignano F, Iuliano L, Rubino G, Tagliaferri VJAM (2016) Abrasive fluidized bed (AFB) finishing of AlSi10Mg substrates manufactured by direct metal laser sintering (DMLS). Addit Manuf 10:15–23. https://doi.org/10.1016/j.addma.2016.01.005

Hiegemann L, Agarwal C, Weddeling C, Tekkaya AE (2016) Reducing the stair step effect of layer manufactured surfaces by ball burnishing. In: AIP Conference Proceedings AIP Publishing. https://doi.org/10.1063/1.4963612

Kaynak Y, Tascioglu E (2019) Post-processing effects on the surface characteristics of Inconel 718 alloy fabricated by selective laser melting additive manufacturing. Progress Addit Manuf. https://doi.org/10.1007/s40964-019-00099-1

Tyagi P, Goulet T, Riso C, Stephenson R, Chuenprateep N, Schlitzer J, Benton C, Garcia-Moreno F (2019) Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit Manuf 25:32–38. https://doi.org/10.1016/j.addma.2018.11.001

Karabulut Y, Tascioglu E, Kaynak Y (2021) Heat treatment temperature-induced microstructure microhardness and wear resistance of Inconel 718 produced by selective laser melting additive manufacturing. Optik 227:163907. https://doi.org/10.1016/j.ijleo.2019.163907

Zhang D, Niu W, Cao X, Liu Z (2015) Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater Sci Eng A 644:32–40. https://doi.org/10.1016/j.msea.2015.06.021

Jiang R, Mostafaei A, Wu Z, Choi A, Guan P-W, Chmielus M, Rollett AD (2020) Effect of heat treatment on microstructural evolution and hardness homogeneity in laser powder bed fusion of alloy 718. Addit Manuf 35:101282. https://doi.org/10.1016/j.addma.2020.101282

Fayed EM, Saadati M, Shahriari D, Brailovski V, Jahazi M, Medraj M (2021) Effect of homogenization and solution treatments time on the elevated-temperature mechanical behavior of Inconel 718 fabricated by laser powder bed fusion. Sci Rep 11(1):1–17. https://doi.org/10.1038/s41598-021-81618-5

Gruber K, Stopyra W, Kobiela K, Madejski B, Malicki M, Kurzynowski T (2022) Mechanical properties of Inconel 718 additively manufactured by laser powder bed fusion after industrial high-temperature heat treatment. J Manuf Process 73:642–659. https://doi.org/10.1016/j.jmapro.2021.11.053

Baicheng Z, Xiaohua L, Jiaming B, Junfeng G, Pan W, Chen-nan S, Muiling N, Guojun Q, Jun W (2017) Study of selective laser melting (SLM) Inconel 718 part surface improvement by electrochemical polishing. Mater Des 116:531–537. https://doi.org/10.1016/j.matdes.2016.11.103

Bertoli US, Wolfer AJ, Matthews MJ, Delplanque J-PR, Schoenung JM (2017) On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater Des 113:331–340. https://doi.org/10.1016/j.matdes.2016.10.037

Carter LN, Wang X, Read N, Khan R, Aristizabal M, Essa K, Attallah MM (2016) Process optimisation of selective laser melting using energy density model for nickel based superalloys. Mater Sci Technol 32(7):657–661. https://doi.org/10.1179/1743284715Y.0000000108

Pal S, Gubeljak N, Hudak R, Lojen G, Rajtukova V, Predan J, Kokol V, Drstvensek I (2019) Tensile properties of selective laser melting products affected by building orientation and energy density. Mater Sci Eng A 743:637–647. https://doi.org/10.1016/j.msea.2018.11.130

Ghayoor M, Lee K, He Y, Chang C-H, Paul BK, Pasebani S (2020) Selective laser melting of 304L stainless steel: role of volumetric energy density on the microstructure texture and mechanical properties. Addit Manuf 32:101011. https://doi.org/10.1016/j.addma.2019.101011

Ciurana J, Hernandez L, Delgado J (2013) Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material. Int J Adv Manuf Technol 68(5–8):1103–1110. https://doi.org/10.1007/s00170-013-4902-4

Teixeira Ó, Silva FJ, Atzeni E (2021) Residual stresses and heat treatments of Inconel 718 parts manufactured via metal laser beam powder bed fusion: an overview. Int J Adv Manuf Technol 113(11):3139–3162. https://doi.org/10.1007/s00170-021-06835-8

Moussaoui K, Rubio W, Mousseigne M, Sultan T, Rezai F (2018) Effects of selective laser melting additive manufacturing parameters of Inconel 718 on porosity microstructure and mechanical properties. Mater Sci Eng A 735:182–190. https://doi.org/10.1016/j.msea.2018.08.037

Salem H, Carter L, Attallah M, Salem H (2019) Influence of processing parameters on internal porosity and types of defects formed in Ti6Al4V lattice structure fabricated by selective laser melting. Mater Sci Eng A 767:138387. https://doi.org/10.1016/j.msea.2019.138387

Yusuf SM, Chen Y, Boardman R, Yang S, Gao N (2017) Investigation on porosity and microhardness of 316L stainless steel fabricated by selective laser melting. Metals 7(2):64. https://doi.org/10.3390/met7020064

Kelbassa I (2006) Qualifizieren des Laserstrahl-Auftragschweißens von BLISKs aus Nickel-und Titanbasislegierungen Aachen Techn Hochsch Diss

Parida RP, Senthilkumar V (2021) Experimental studies of defect generation in selective laser melted Inconel 718 alloy. Mater Today: Proc 39:1372–1377. https://doi.org/10.1016/j.matpr.2020.04.698

Shishkovsky I, Morozov Y, Smurov I (2009) Nanostructural self-organization under selective laser sintering of exothermic powder mixtures. Appl Surf Sci 255(10):5565–5568. https://doi.org/10.1016/j.apsusc.2008.09.090

Wang L-z, Wang S, Wu J-j (2017) Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt Laser Technol 96:88–96. https://doi.org/10.1016/j.optlastec.2017.05.006

Tolochko NK, Mozzharov SE, Yadroitsev IA, Laoui T, Froyen L, Titov VI, Ignatiev MB (2004) Balling processes during selective laser treatment of powders. Rapid Prototyp J. https://doi.org/10.1108/13552540410526953

Van Elsen M (2007) Complexity of Selective Laser Melting: a new optimisation approach

Mumtaz K, Hopkinson N (2010) Selective laser melting of thin wall parts using pulse shaping. J Mater Process Technol 210(2):279–287. https://doi.org/10.1016/j.jmatprotec.2009.09.011

Fonseca EB, Gabriel AH, Araújo LC, Santos PL, Campo KN, Lopes ES (2020) Assessment of laser power and scan speed influence on microstructural features and consolidation of AISI H13 tool steel processed by additive manufacturing. Addit Manuf 34:101250. https://doi.org/10.1016/j.addma.2020.101250

Leuders S, Thöne M, Riemer A, Niendorf T, Tröster T, Richard HA, Maier HJ (2013) On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: fatigue resistance and crack growth performance. Int J Fatigue 48:300–307. https://doi.org/10.1016/j.ijfatigue.2012.11.011

Huang J, Li M, Wang J, Pei Z, Mclntyre P, Ma C (2021) Selective laser melting of tungsten: effects of hatch distance and point distance on pore formation. J Manuf Process 61:296–302. https://doi.org/10.1016/j.jmapro.2020.11.034

Leung CLA, Marussi S, Towrie M, Atwood RC, Withers PJ, Lee PD (2019) The effect of powder oxidation on defect formation in laser additive manufacturing. Acta Mater 166:294–305. https://doi.org/10.1016/j.actamat.2018.12.027

King WE, Barth HD, Castillo VM, Gallegos GF, Gibbs JW, Hahn DE, Kamath C, Rubenchik AM (2014) Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J Mater Process Technol 214(12):2915–2925. https://doi.org/10.1016/j.jmatprotec.2014.06.005

Kasperovich G, Haubrich J, Gussone J, Requena G (2016) Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater Des 105:160–170. https://doi.org/10.1016/j.matdes.2016.05.070

Balbaa M, Mekhiel S, Elbestawi M, McIsaac J (2020) On selective laser melting of Inconel 718: densification surface roughness and residual stresses. Mater Des 193:108818. https://doi.org/10.1016/j.matdes.2020.108818

Arısoy YM, Criales LE, Özel T, Lane B, Moylan S, Donmez A (2017) Influence of scan strategy and process parameters on microstructure and its optimization in additively manufactured nickel alloy 625 via laser powder bed fusion. Int J Adv Manuf Technol 90(5):1393–1417. https://doi.org/10.1007/s00170-016-9429-z

Carter LN, Martin C, Withers PJ, Attallah MM (2014) The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J Alloys Compd 615:338–347. https://doi.org/10.1016/j.jallcom.2014.06.172

Nadammal N, Cabeza S, Mishurova T, Thiede T, Kromm A, Seyfert C, Farahbod L, Haberland C, Schneider JA, Portella PD (2017) Effect of hatch length on the development of microstructure texture and residual stresses in selective laser melted superalloy Inconel 718. Mater Des 134:139–150. https://doi.org/10.1016/j.matdes.2017.08.049

Kusuma C (2016) The effect of laser power and scan speed on melt pool characteristics of pure titanium and Ti-6Al-4V alloy for selective laser melting

Lippold JC, Kiser SD, DuPont JN (2011) Welding metallurgy and weldability of nickel-base alloys. John Wiley & Sons, Hoboken

Huang W, Yang J, Yang H, Jing G, Wang Z, Zeng X (2019) Heat treatment of Inconel 718 produced by selective laser melting: microstructure and mechanical properties. Mater Sci Eng A 750:98–107. https://doi.org/10.1016/j.msea.2019.02.046

Wang X, Kang J, Wang T, Wu P, Feng T, Zheng L (2019) Effect of layer-wise varying parameters on the microstructure and soundness of selective laser melted INCONEL 718 alloy. Mater 12(13):2165. https://doi.org/10.3390/ma12132165

Popovich V, Borisov E, Popovich A, Sufiiarov VS, Masaylo D, Alzina L (2017) Functionally graded Inconel 718 processed by additive manufacturing: crystallographic texture anisotropy of microstructure and mechanical properties. Mater Des 114:441–449. https://doi.org/10.1016/j.matdes.2016.10.075

Liu X, Zhao C, Zhou X, Shen Z, Liu W (2019) Microstructure of selective laser melted AlSi10Mg alloy. Mater Des 168:107677. https://doi.org/10.1016/j.matdes.2019.107677

Zhou L, Mehta A, McWilliams B, Cho K, Sohn Y (2019) Microstructure precipitates and mechanical properties of powder bed fused Inconel 718 before and after heat treatment. J Mater Process Technol 35(6):1153–1164. https://doi.org/10.1016/j.jmst.2018.12.006

Komarasamy M, Shukla S, Williams S, Kandasamy K, Kelly S, Mishra RS (2019) Microstructure fatigue and impact toughness properties of additively manufactured nickel alloy 718. Addit Manuf 28:661–675. https://doi.org/10.1016/j.addma.2019.06.009

Anderson M, Thielin A-L, Bridier F, Bocher P, Savoie J (2017) δ Phase precipitation in Inconel 718 and associated mechanical properties. Mater Sci Eng A 679:48–55. https://doi.org/10.1016/j.msea.2016.09.114

Özer S (2020) Effect of post-processing heat treatment on the mechanical properties of Inconel 718 fabricated by selective laser melting Fen Bilimleri Enstitüsü

Raghavan S, Zhang B, Wang P, Sun C-N, Nai MLS, Li T, Wei J (2017) Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater Manuf Process 32(14):1588–1595. https://doi.org/10.1080/10426914.2016.1257805

Tascioglu E, Karabulut Y, Kaynak Y (2020) Influence of heat treatment temperature on the microstructural mechanical and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing. Int J Adv Manuf Technol 107(5):1947–1956. https://doi.org/10.1007/s00170-020-04972-0

Wang W, Wang S, Zhang X, Chen F, Xu Y, Tian Y (2021) Process parameter optimization for selective laser melting of Inconel 718 superalloy and the effects of subsequent heat treatment on the microstructural evolution and mechanical properties. J Manuf Process 64:530–543. https://doi.org/10.1016/j.jmapro.2021.02.004

Teng Q, Li S, Wei Q, Shi Y (2021) Investigation on the influence of heat treatment on Inconel 718 fabricated by selective laser melting: microstructure and high temperature tensile property. J Manuf Process 61:35–45. https://doi.org/10.1016/j.jmapro.2020.11.002

Fayed EM, Saadati M, Shahriari D, Brailovski V, Jahazi M, Medraj M (2021) Optimization of the post-process heat treatment of Inconel 718 superalloy fabricated by laser powder bed fusion process. Metals 11(1):144. https://doi.org/10.3390/met11010144

Balbaa M, Elbestawi M, McIsaac J (2019) An experimental investigation of surface integrity in selective laser melting of Inconel 625. Int J Adv Manuf Technol 104(9):3511–3529. https://doi.org/10.1007/s00170-019-03949-y

Liu F, Lin X, Yang G, Song M, Chen J, Huang W (2011) Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy. Opt Laser Technol 43(1):208–213. https://doi.org/10.1016/j.optlastec.2010.06.015

Kaya M, Sunay N, Kaynak Y (2021) Comparison of finite element and empirical model prediction of surface residual stress in Inconel 718 parts fabricated by laser powder bed fusion additive manufacturing. J Addit Manuf Technol 1(3):592–592

Cherry J, Davies H, Mehmood S, Lavery N, Brown S, Sienz J (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76(5):869–879. https://doi.org/10.1007/s00170-014-6297-2

Xu Y, Gong Y, Li P, Yang Y, Qi Y (2020) The effect of laser power on the microstructure and wear performance of IN718 superalloy fabricated by laser additive manufacturing. Int J Adv Manuf Technol 108(7):2245–2254. https://doi.org/10.1007/s00170-020-05172-6

Zhao X, Chen J, Lin X, Huang W (2008) Study on microstructure and mechanical properties of laser rapid forming Inconel 718. Mater Sci Eng A 478(1–2):119–124. https://doi.org/10.1016/j.msea.2007.05.079

Brown D, Li C, Liu Z, Fang X, Guo Y (2018) Surface integrity of Inconel 718 by hybrid selective laser melting and milling. Virtual Phys Prototyp 13(1):26–31. https://doi.org/10.1080/17452759.2017.1392681

Wang Z, Guan K, Gao M, Li X, Chen X, Zeng X (2012) The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J Alloys Compd 513:518–523. https://doi.org/10.1016/j.jallcom.2011.10.107

Vilaro T, Colin C, Bartout J-D, Nazé L, Sennour M (2012) Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater Sci Eng A 534:446–451. https://doi.org/10.1016/j.msea.2011.11.092

Yu Z, Xu Z, Guo Y, Sha P, Liu R, Xin R, Li L, Chen L, Wang X, Zhang Z (2022) Analysis of microstructure mechanical properties wear characteristics and corrosion behavior of SLM-NiTi under different process parameters. J Manuf Process 75:637–650. https://doi.org/10.1016/j.jmapro.2022.01.010

Zhao Z, Li J, Bai P, Qu H, Liang M, Liao H, Wu L, Huo P, Liu H, Zhang J (2019) Microstructure and mechanical properties of TiC-reinforced 316L stainless steel composites fabricated using selective laser melting. Metals 9(2):267. https://doi.org/10.3390/met9020267

Wang T, Wang C, Li J, Chai L, Hu X, Ma Y, Huang Y (2021) Microstructure and wear properties of laser-clad NiCo alloy coating on Inconel 718 alloy. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.160412

Sharma S, Sangal S, Mondal K (2013) On the optical microscopic method for the determination of ball-on-flat surface linearly reciprocating sliding wear volume. Wear 300(1–2):82–89. https://doi.org/10.1016/j.wear.2013.01.107

Yaman N, Sunay N, Kaya M, Kaynak Y (2022) Enhancing surface integrity of additively manufactured Inconel 718 by roller burnishing process. Procedia CIRP 108:681–686. https://doi.org/10.1016/j.procir.2022.03.106

Zhao Z, Qu H, Bai P, Li J, Wu L, Huo P (2018) Friction and wear behaviour of Inconel 718 alloy fabricated by selective laser melting after heat treatments. Philos Mag Lett 98(12):547–555. https://doi.org/10.1080/09500839.2019.1597991

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sunay, N., Kaya, M., Yılmaz, M.S. et al. Effects of heat treatment on surface integrity and wear performance of Inconel 718 alloy fabricated by laser powder bed fusion process additive manufacturing under different laser power and scanning speed parameters. J Braz. Soc. Mech. Sci. Eng. 45, 430 (2023). https://doi.org/10.1007/s40430-023-04298-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04298-4