Abstract

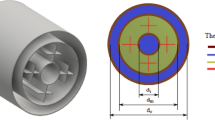

In this study, novel longitudinal arc fins were proposed to increase the melting performance of phase change material in a latent heat thermal energy storage device. In order to optimize these innovative arc fins, various configurations of these fins were designed by changing the arc length, fin angle and eccentricity of the inner tube. In order to evaluate the performance of the new fins, five arrangements of traditional rectangular plate fins as well as a bare tube case were also numerically simulated. In all examined cases, the volume fraction of fins was considered constant and equal to 6.13%. Consequently, the best configuration of innovative fins was found by comparing melting characteristics of them with those of traditional rectangular plate fins. In addition, the effects of Al2O3 nanoparticles on melting performance of some designed arc fins including the most efficient ones were evaluated. Results revealed that the best case was able to reduce the total melting time by 96.5% with respect to the bare tube and 67.7% with respect to 12 number of rectangular fins. In comparison with the pure PCM as the base case, addition of 2% and 5% nanoparticles can lead to time savings of 10.44% and 12.36%, respectively.

Similar content being viewed by others

Abbreviations

- \(k\) :

-

Thermal conductivity (W m−1 K−1)

- Cp:

-

Specific heat (J Kg−1 K−1)

- \(L_{{\text{f}}}\) :

-

Latent heat of fusion (J Kg−1)

- P :

-

Pressure

- \({\varvec{u}}\) :

-

Velocity vector

- g :

-

Gravity acceleration

- t :

-

Time

- \(C_{{{\text{mz}}}}\) :

-

Mushy zone constant (Kg m− 3 s− 1)

- \(T_{{\text{s}}}\) :

-

Solidus temperature phases (K)

- \(T_{{\text{l}}}\) :

-

Liquidus temperature (K)

- \(T_{{{\text{ref}}}}\) :

-

Reference temperature (K)

- \(h_{{{\text{sens}}}}\) :

-

Sensible enthalpy

- \(h_{{{\text{lat}}}}\) :

-

Latent enthalpy

- \(h_{{{\text{ref}}}}\) :

-

Enthalpy at reference temperature

- \(k_{{\text{b}}}\) :

-

Boltzmann constant

- \(h_{{\text{f}}}\) :

-

Fin height (mm)

- \(t_{{\text{f}}}\) :

-

Fin thickness (mm)

- e :

-

Eccentric distance (mm)

- E :

-

Eccentricity ratio (mm)

- \(R_{{\text{s}}}\) :

-

Shell radius (mm)

- \(R_{{\text{t}}}\) :

-

Tube radius (mm)

- a :

-

Internal and external radius (mm)

- \(V_{{\text{f}}}\) :

-

Fin volume (m3)

- \(V_{{\text{t}}}\) :

-

Total volume (m3)

- \(\lambda\) :

-

Liquid fraction

- \(\theta\) :

-

Angle between two fins

- \(\varepsilon\) :

-

A small number

- \(\beta\) :

-

Thermal expansion coefficient (k−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\mu\) :

-

Kinematic viscosity (N s m− 2)

- \(\varphi_{{\text{n}}}\) :

-

Percentage of nanoparticles

- \(\phi_{{\text{f}}}\) :

-

Fin volume fraction

- FVM:

-

Finite volume method

- PCM:

-

Phase change material

- NEPCM:

-

Nano-phase change material

- HTF:

-

Heat transfer fluid

- TES:

-

Thermal energy storage

- LH-TES:

-

Latent heat thermal energy storage

- TC-TES:

-

Thermochemical thermal energy storage

- SH-TES:

-

Sensible heat thermal energy storage

- RF:

-

Rectangular fin

- CAF:

-

Concentric arc fin

- BT:

-

Bare tube

- EAF:

-

Eccentric arc fin

- PCM:

-

Phase change material

- n :

-

Nanoparticle

- NEPCM:

-

Nano-phase change material

- s :

-

Solidus

- l :

-

Liquidus

- ref:

-

Reference

References

Li G, Qian S, Lee H, Hwang Y, Radermacher R (2014) Experimental investigation of energy and exergy performance of short term adsorption heat storage for residential application. Energy 65:675–691

Han X, Wang L, Ling H, Ge Z, Lin X, Dai X, Chen H (2022) Critical review of thermochemical energy storage systems based on cobalt, manganese, and copper oxides. Renew Sustain Energy Rev 158:112076

Desai F, Sunku PJ, Muthukumar P, Rahman MM (2021) Thermochemical energy storage system for cooling and process heating applications: A review. Energy Convers Manage 229:113617

Li G (2016) Sensible heat thermal storage energy and exergy performance evaluations. Renew Sustain Energy Rev 53:897–923

Chaatouf D, Salhi M, Raillani B, Amraqui S, Mezrhab A, Naji H (2022) Parametric analysis of a sensible heat storage unit in an indirect solar dryer using computational fluid dynamics. J Energy Storage 49:104075

Santos A, Almeida F, Neto F (2021) Development of rock sensible heat storage system: Modeling of a hematite reservoir. J Energy Storage 40:102818

Du Y, Ding Y (2016) Towards improving charge/discharge rate of latent heat thermal energy storage (LHTES) by embedding metal foams in phase change materials (PCMs). Chem Eng Process 108:181–188

Shinde TU, Dalvi VH, Mathpati CS, Shenoy N, Panse SV, Joshi JB (2022) Heat transfer investigation of PCM pipe bank thermal storage for space heating application. Chem Eng Process - Process Intensificat 180:108791

Shehzad SA, Alshuraiaan B, Kamel MS, Izadi M, Ambreen T (2021) Influence of fin orientation on the natural convection of aqueous-based nano-encapsulated PCMs in a heat exchanger equipped with wing-like fins. Chem Eng Process - Process Intensificat 160:108287

Huu-Quan D, Sheremet M, Kamel MS, Izadi M (2020) Investigation of thermal-hydro dynamical behavior on nano-encapsulated PCM suspension: effect of fin position, fractioning and aspect ratio. Chem Eng Process - Process Intensificat 157:108122

Abdulateef AM, Mat S, Abdulateef J, Sopian K, Al-Abidi AA (2018) Geometric and design parameters of fins employed for enhancing thermal energy storage systems: a review. Renew Sustain Energy Rev 82:1620–1635

Alva G, Lin Y, Fang G (2018) An overview of thermal energy storage systems. Energy 144:341–378

Laing D, Bauer T, Breidenbach N, Hachmann B, Johnson M (2013) Development of high temperature phase-change-material storages. Appl Energy 109:497–504

Muhammad MD, Badr O (2017) Performance of a finned, latent-heat storage system for high temperature applications. Appl Therm Eng 116:799–810

Pizzolato A, Sharma A, Maute K, Sciacovelli A, Verda V (2017) Design of effective fins for fast PCM melting and solidification in shell-and-tube latent heat thermal energy storage through topology optimization. Appl Energy 208:210–227

Pizzolato A, Sharma A, Ge R, Maute K, Verda V, Sciacovelli A (2020) Maximization of performance in multi-tube latent heat storage – Optimization of fins topology, effect of materials selection and flow arrangements. Energy 203:114797

Vogel J, Johnson M (2019) Natural convection during melting in vertical finned tube latent thermal energy storage systems. Appl Energy 246:38–52

Mat S, Al-Abidi AA, Sopian K, Sulaiman MY, Mohammad AT (2013) Enhance heat transfer for PCM melting in triplex tube with internal–external fins. Energy Convers Manage 74:223–236

Dhaidan NS, Khodadadi JM, Al-Hattab TA, Al-Mashat SM (2013) Experimental and numerical investigation of melting of phase change material/nanoparticle suspensions in a square container subjected to a constant heat flux. Int J Heat Mass Transf 66:672–683

Mahdi JM, Nsofor EC (2016) Solidification of a PCM with nanoparticles in triplex-tube thermal energy storage system. Appl Therm Eng 108:596–604

Motahar S, Alemrajabi AA, Khodabandeh R (2017) Experimental study on solidification process of a phase change material containing TiO2 nanoparticles for thermal energy storage. Energy Convers Manage 138:162–170

Raam DG, Sreekumar A (2014) Influence of nanomaterials on properties of latent heat solar thermal energy storage materials – A review. Energy Convers Manage 83:133–148

Deng Z, Liu X, Zhang C, Huang Y, Chen Y (2017) Melting behaviors of PCM in porous metal foam characterized by fractal geometry. Int J Heat Mass Transf 113:1031–1042

Liu H, Ahmad S, Shi Y, Zhao J (2021) A parametric study of a hybrid battery thermal management system that couples PCM/copper foam composite with helical liquid channel cooling. Energy 231:120869

Huang S, Lu J, Li Y (2022) Numerical study on the influence of inclination angle on the melting behaviour of metal foam-PCM latent heat storage units. Energy 239:122489

Pu L, Zhang S, Xu L, Ma Z, Wang X (2021) Numerical study on the performance of shell-and-tube thermal energy storage using multiple PCMs and gradient copper foam. Renewable Energy 174:573–589

Yu XK, Tao YB, He Y, Lv ZC (2022) Temperature control performance of high thermal conductivity metal foam/paraffin composite phase change material: an experimental study. J Energy Storage 46:103930

Mahdi JM, Nsofor EC (2017) Melting enhancement in triplex-tube latent heat energy storage system using nanoparticles-metal foam combination. Appl Energy 191:22–34

Mahdi JM, Nsofor EC (2017) Solidification enhancement in a triplex-tube latent heat energy storage system using nanoparticles-metal foam combination. Energy 126:501–512

Hassani Soukht Abandani M, Domiri Ganji D (2021) Melting effect in triplex-tube thermal energy storage system using multiple PCMs-porous metal foam combination. J Energy Storage 43:103154

Rathod MK, Banerjee J (2015) Thermal performance enhancement of shell and tube Latent Heat Storage Unit using longitudinal fins. Appl Therm Eng 75:1084–1092

Sciacovelli A, Gagliardi F, Verda V (2015) Maximization of performance of a PCM latent heat storage system with innovative fins. Appl Energy 137:707–715

Wołoszyn J, Szopa K (2023) A combined heat transfer enhancement technique for shell-and-tube latent heat thermal energy storage. Renew Energy 202:1342–1356

Ye W, Khodadadi J (2022) Effects of arrow-shape fins on the melting performance of a horizontal shell-and-tube latent heat thermal energy storage unit. J Energy Storage 54:105201

Palmer B, Arshad A, Yang Y, Wen C (2023) Energy storage performance improvement of phase change materials-based triplex-tube heat exchanger (TTHX) using liquid–solid interface-informed fin configurations. Appl Energy 333:120576

Modi N, Wang X, Negnevitsky M (2023) Numerical investigation into selecting the most suitable shell-to-tube diameter ratio for horizontal latent heat thermal energy storage. Energy Sustain Dev 73:188–204

Mao Q, Zhu Y, Li T (2023) Study on heat storage performance of a novel bifurcated finned shell-tube heat storage tank. Energy 263:125636

Mao Q, Hu X, Li T (2022) Study on heat storage performance of a novel vertical shell and multi-finned tube tank. Renew Energy 193:76–88

Yusuf YM, Avcı M, Aydın O, Akgun M (2014) Effect of eccentricity on melting behavior of paraffin in a horizontal tube-in-shell storage unit: An experimental study. Sol Energy 101:291–298

Khan LA, Khan MM, Ahmed HF, Irfan M, Brabazon D, Ahad IU (2021) Dominant roles of eccentricity, fin design, and nanoparticles in performance enhancement of latent thermal energy storage unit. Journal of Energy Storage 43:103181

Zhou H, Wei L-Y, Cai Q-L, Ren X-Z, Bi C-W, Zhong D, Liu Y (2021) Annulus eccentric analysis of the melting and solidification behavior in a horizontal tube-in-shell storage unit. Appl Therm Eng 190:116752

Safari V, Abolghasemi H, Darvishvand L, Kamkari B (2021) Thermal performance investigation of concentric and eccentric shell and tube heat exchangers with different fin configurations containing phase change material. J Energy Storage 37:102458

Ul Hasnain F, Irfan M, Khan MM, Khan LA, Ahmed H (2021) Melting performance enhancement of a phase change material using branched fins and nanoparticles for energy storage applications. Journal of Energy Storage 38:102513

Liu X, Huang Y, Zhang X, Zhang C, Zhou B (2020) Investigation on charging enhancement of a latent thermal energy storage device with uneven tree-like fins. Appl Therm Eng 179:115749

Sciacovelli A, Colella F, Verda V (2013) Melting of PCM in a thermal energy storage unit: Numerical investigation and effect of nanoparticle enhancement. Int J Energy Res 37:1610–1623

Mahdi JM, Lohrasbi S, Ganji DD, Nsofor EC (2018) Accelerated melting of PCM in energy storage systems via novel configuration of fins in the triplex-tube heat exchanger. Int J Heat Mass Transf 124:663–676

Mahdi JM, Lohrasbi S, Ganji DD, Nsofor EC (2019) Simultaneous energy storage and recovery in the triplex-tube heat exchanger with PCM, copper fins and Al2O3 nanoparticles. Energy Convers Manage 180:949–961

Yuan Y, Cao X, Xiang B, Du Y (2016) Effect of installation angle of fins on melting characteristics of annular unit for latent heat thermal energy storage. Sol Energy 136:365–378

Voller VR, Prakash C (1987) A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int J Heat Mass Transf 30:1709–1719

Mahdi JM, Nsofor EC (2017) Melting enhancement in triplex-tube latent thermal energy storage system using nanoparticles-fins combination. Int J Heat Mass Transf 109:417–427

Alizadeh M, Pahlavanian MH, Tohidi M, Ganji DD (2020) Solidification expedition of phase change material in a triplex-tube storage unit via novel fins and SWCNT nanoparticles. J Energy Storage 28:101188

Vajjha RS, Das DK (2009) Experimental determination of thermal conductivity of three nanofluids and development of new correlations. Int J Heat Mass Transf 52:4675–4682

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amini, Y., Abbasirad, M.H. Melting performance enhancement of a latent thermal energy storage device using innovative arc fins and nanoparticles. J Braz. Soc. Mech. Sci. Eng. 45, 298 (2023). https://doi.org/10.1007/s40430-023-04227-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04227-5