Abstract

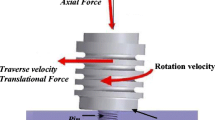

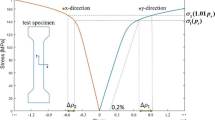

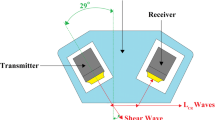

The present work evaluates the use of acoustoelasticity techniques to measure residual stresses produced by friction stir welding (FSW) in joints of 5052 aluminum alloys after milling to develop an inspection tool for production lines. A set of experiments was adequately planned to obtain the acoustoelastic coefficient of the material, considering the welding zones. Then, the magnitude and distribution of longitudinal residual stresses throughout the perpendicular direction were obtained using an improved measurement procedure for the ultrasonic method. The technique was shown to be effective for the proposed application, as the results were validated by another residual stress measurement method. It was demonstrated that the magnitude of the stresses depends on the combination of FSW parameters, which must be selected according to the characteristics of the alloy. The results showed that lower rotational and traverse tool speed produced higher residual stress levels, indicating a significant propensity to failure that results in a decrease in welding quality.

Similar content being viewed by others

References

Stojanovic B, Epler I, et al (2018) Application of aluminum and aluminum alloys in engineering. Applied Engineering Letters

Hernandez FCR, Ramírez JMH, Mackay R (2017) Al-Si alloys: automotive, aeronautical, and aerospace applications. Springer, Cham

Ueyama T, Tong H, Harada S, Passmore R, Ushio M (2005) Ac pulsed GMAW improves sheet metal joining. Weld J 84(2):40–45

Kang M, Kim C (2015) Joining al 5052 alloy to aluminized steel sheet using cold metal transfer process. Mater Des 81:95–103

Kumbhar N, Bhanumurthy K (2012) Friction stir welding of al 5052 with al 6061 alloys. J Metall 2012

Hansen SR, Vivek A, Daehn GS (2015) Impact welding of aluminum alloys 6061 and 5052 by vaporizing foil actuators: heat-affected zone size and peel strength. J Manuf Sci Eng 137:5

Akca E, Gürsel A (2016) Solid state welding and application in aeronautical industry. Period Eng Nat Sci (PEN) 4(1)

Rathod M, Karale T (2014) Friction stir welding of aluminium-alloys

Thomas W, Nicholas E, Needham J, Murch M, Templesmith P, Dawes C (1991) International patent application no. 9125978.8. Technical report, PCT/GB92/02203 and GB patent application

Mishra RS, Ma Z (2005) Friction stir welding and processing. Mater Sci Eng: R: Rep 50(1–2):1–78

Webster G, Ezeilo A (2001) Residual stress distributions and their influence on fatigue lifetimes. Int J Fatigue 23:375–383

Lu J (1996) Handbook of measurement of residual stresses. Fairmont press, Georgia

Rossini N, Dassisti M, Benyounis K, Olabi A-G (2012) Methods of measuring residual stresses in components. Mater Des 35:572–588

Hauk V (1997) Structural and residual stress analysis by nondestructive methods: Evaluation-application-assessment

Bahadur A, Kumar BR, Kumar AS, Sarkar G, Rao J (2004) Development and comparison of residual stress measurement on welds by various methods. Mater Sci Technol 20(2):261–269

Leon-Salamanca T, Bray D (1996) Residual stress measurement in steel plates and welds using critically refracted longitudinal (LCR) waves. Res Nondestruct Eval 7(4):169–184

Tanala E, Bourse G, Fremiot M, De Belleval J (1995) Determination of near surface residual stresses on welded joints using ultrasonic methods. NDT & E Int 28(2):83–88

Hughes DS, Kelly J (1953) Second-order elastic deformation of solids. Phys Rev 92(5):1145

Egle D, Bray D (1976) Measurement of acoustoelastic and third-order elastic constants for rail steel. J Acoust Soc Am 60(3):741–744

Vangi D, Virga A (2007) A practical application of ultrasonic thermal stress monitoring in continuous welded rails. Exper Mech 47(5):617–623

Minicuci DJ, dos Santos Júnior AA, Andrino MH, de Carvalho Santos F (2007) Stress evaluation of railroad forged wheels by ultrasonic testing. J Test Eval 35(1):66–74

Santos AA, dos Santos GF, de Santos FC, Andrino MH, Rosário JM (2009) Application of LCR waves to evaluate residual stresses in the RIM of railroad forged wheels. J Nondestruct Eval 28(2):91–100

Andrino M, Caetano S, dos Santos Junior A, Gonçalves R (2002) Avaliação das tensões em chapas de alumínio 7050 utilizando o efeito acustoelástico. In: 6th Conference About Technology for Equipments-COTEQ. Salvador-Brazil

Grzybowski IF, Zientarski RR, Buenos AA, dos Santos Junior AA (2022) Residual stresses in weld bead of low carbon steel plates welded by gmaw using lcr waves. J Brazilian Soc Mech Sci Eng 44(7):1–15

Walaszek H, Lieurade H, Peyrac C, Hoblos J, Rivenez J (2002) Potentialities of ultrasonics for evaluating residual stresses: Influence of microstructure. J Pressure Vessel Technol 124(3):349–353

Liu B, Li J, Dong S, Shu F (2020) Correction for microstructure effect on residual stress measurement of SR-FSW joint with LCR wave. Russian J Nondestruct Test 56(2):131–140

International A (1990) Metals handbook vol. 2: properties and selection: nonferrous alloys and special-purpose materials. ASM

Vasco G, Rudolf Z, Silvia L (2003) Friction stir weld zone evaluation by image analysing techniques

Buenos AA, dos Santos Junior AA, Rodrigues AR, Tokimatsu RC (2013) Application of acoustoelasticity to measure the stress generated by milling in ASTM a36 steel plates. J Brazilian Soc Mech Sci Eng 35(4):525–536

Jacobus K, DeVor R, Kapoor S (2000) Machining-induced residual stress: experimentation and modeling. J Manuf Sci Eng 122(1):20–31

Heinz B, Skrotzki B (2002) Characterization of a friction-stir-welded aluminum alloy 6013. Metall Mater Trans B 33(3):489–498

Threadgill L (1997) Friction stir welds in aluminium alloys-preliminary microstructural assessment. TWI Bull 30:33

Garcia Ruano SA, dos Santos Junior AA (2022) Quality index for friction stir welds in 7050 aluminum plates. Mater Des 222:111052

Bray DE, Stanley RK (2018) Nondestructive evaluation: A tool in design, manufacturing, and service. CRC Press, Boca Raton

Murnaghan F (1951) Finite deformation of an elastic solid. Chapman and Hall, London

Song W, Xu C, Pan Q, Song J (2016) Nondestructive testing and characterization of residual stress field using an ultrasonic method. Chin J Mech Eng 29(2):365–371

Liu H, Li Y, Li T, Zhang X, Liu Y, Liu K, Wang Y (2018) Influence factors analysis and accuracy improvement for stress measurement using ultrasonic longitudinal critically refracted (LCR) wave. Appl Acoust 141:178–187

ASTM E (2008) 837-08. Standard test method for determining residual stresses by the hole-drilling strain-gage method

Schajer G (1988) Measurement of non-uniform residual stresses using the hole-drilling method. part ii–practical application of the integral method

Rendler N, Vigness I (1966) Hole-drilling strain-gage method of measuring residual stresses. Exper Mech 6(12):577–586

Rutherford A (2011) Anova and ancova: a glm approach

Hadji I, Badji R, Gaceb M, Kherrouba N, Rabahi L (2018) Investigation of the effect of aluminum alloy position on residual stresses in dissimilar FSW weld by using the ultrasonic method. In: IOP Conference Series: Materials Science and Engineering, vol. 461, p 012022. IOP Publishing

Xu X, Yu H, Lin Z (2020) Study of residual stress variation with depth of friction stir welded aluminium plates with different thicknesses. Sci Technol Weld Join 25(4):297–302

Buenos AA, Pereira P, Mei PR, dos Santos AA (2014) Influence of grain size on the propagation of LCR waves in low carbon steell. J Nondestruct Eval 33(4):562–570

Hadji I, Badji R, Gaceb M, Kherrouba N, Rabahi L (2018) Investigation of the effect of aluminum alloy position on residual stresses in dissimilar fsw weld by using the ultrasonic method. In: IOP Conference Series: Materials Science and Engineering, vol. 461, p 012022. IOP Publishing

Acknowledgements

To Lightweight Structures Laboratory (LEL) at the Institute for Technological Research (IPT) in Brazil, especially Andre Ferrara Carunchio and Mario Batalha, for their collaboration in performing the welding. The authors acknowledge the financial support given by CAPES and the São Paulo Research Foundation, FAPESP (Fundação de Amparo à Pesquisa de São Paulo), grant number 2018/18546-3 and CNPq, grant number 315304/2018-9. Shirley Garcia is also grateful to SENESCYT (Secretaría de Educación Superior, Ciencia, Tecnología e Innovación), grant number 2015-AR2Q8297.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Garcia Ruano, S.A., Delijaicov, S. & dos Santos Junior, A.A. Acoustoelasticity to measure residual stresses in plates of 5052 aluminum joined by FSW. J Braz. Soc. Mech. Sci. Eng. 45, 82 (2023). https://doi.org/10.1007/s40430-022-03998-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03998-7