Abstract

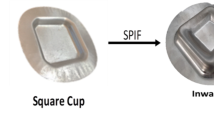

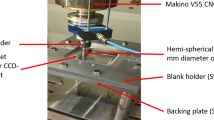

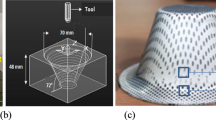

The adaption of circular economy strategies has become increasingly necessary in current times. Researches need to be addressed on finding alternative processes or the modification of the existing processes in order to reprocess End-of-Life (EoL) components and consequently recover both materials and their functions. This research paper focuses on the use of single point incremental forming (SPIF) process for the Reshaping of sheet metal EoL components. Uniaxial and biaxial pre-straining was performed on AA5754 sheets to imitate an end-of-life component, and SPIF operations were carried out so as to obtain reshaped components. In previous works, the authors have proven the technical feasibility of the said approach. The present work is focused on analyzing the possible variation in formability as well as in geometrical accuracy of SPIF process when utilized to reform components. An experimental campaign involving the variation of the pre-straining levels as well as the type (uniaxial and biaxial) was developed, and the resulting formability and geometrical accuracy of the subsequent SPIF operations were then analyzed. Results showed that SPIF is a perfect candidate as Reshaping process. In fact, a very limited reduction in formability as well as the no worsening in geometrical accuracy performance was observed on the different pre-straining paths here analyzed.

Similar content being viewed by others

References

Olivetti EA, Cullen JM (2019) Toward a sustainable materials system. Science 360(6396):1396–1398

IEA (2019) Material efficiency in clean energy transitions. IEA, Paris. https://doi.org/10.1787/aeaaccd8-en

Tolio T, Bernard A, Colledani M, Kara S, Seliger G, Duflou JR, Battaia O, Takata S (2017) Design, management and control of demanufacturing and remanufacturing systems. CIRP Ann Manuf Technol 66:585–609

Li X, Baffari D, Reynolds AP (2018) Friction stir consolidation of aluminum machining chips. Int J Adv Manuf Technol 94(5–8):2031–2042

Duflou JR, Tekkaya AE, Haase M, Welo T, Vanmeensel K, Kellens K, Dewulf W, Paraskevas D (2015) Environmental assessment of solid state recycling routes for aluminium alloys: Can solid state processes significantly reduce the environmental impact of aluminium recycling? CIRP Ann Manuf Technol 64:37–40

Baffari D, Reynolds AP, Masnata A, Fratini L, Ingarao G (2019) Friction stir extrusion to recycle aluminum alloys scraps: Energy efficiency characterization. J Manuf Process 43:63–69

Buffa G, Baffari D, Ingarao G, Fratini L (2020) Uncovering technological and environmental potentials of aluminum alloy scraps recycling through friction stir consolidation. Int J Precis Eng Manuf-Green Technol 7:955–964

Cooper DR, Allwood JM (2012) Reusing steel and aluminum components at end of product life. Environ Sci Technol 46:10334–10340

Sutherland JW, Adler DP, Haapala KR, Kumar V (2008) A comparison of manufacturing and remanufacturing energy intensities with application to diesel engine production. CIRP Ann Manuf Technol 57:5–8

D’Adamo I, Rosa P (2016) Remanufacturing in industry: advices from the field. Int J Adv Manuf Technol 86(9–12):2575–2584

Zhang K, Li D, Gui H, Li Z (2019) An adaptive slicing algorithm for laser cladding remanufacturing of complex components. Int J Adv Manuf Technol 101(9–12):2873–2887

Zhang X, Cui W, Li W, Liou F (2019) Effects of tool path in remanufacturing cylindrical components by laser metal deposition. Int J Adv Manuf Technol 100(5–8):1607–1617

Tilwankar AK, Mahindrakar AB, Asolekar SR (2008) Steel recycling resulting from ship dismantling in India: implications for green house gas emissions. Dismantl Obs Vessels 2008:1–10

Brosius A, Hermes M, Ben Khalif N, Trompeter M, Tekkaya AE (2019) Innovation by forming technology: motivation for research. Int J Mater Form 2:29–38

Takano H, Kitazawa K, Goto T (2008) Incremental forming of nonuniform sheet metal: possibility of cold recycling process of sheet metal waste. Int J Mach Tools Manuf 48:477–482

Abu-Farha FK, Khraisheh MK (2008) An integrated approach to the Superplastic Forming of lightweight alloys: towards sustainable manufacturing. Int J Sustain Manuf 1:18–40

Ingarao G, Zaheer O, Campanella D, Fratini L (2020) Re-forming end-of-life components through single point incremental forming. Manuf Lett 24:132–135

Zaheer O, Ingarao G, Di Lorenzo R, Fratini L (2021) On the effectiveness of spif process to re-form end-of-life components as compared to conventional forming approach. Key Eng Mater 883:201–208

Zaheer O, Ingarao G, Pirrotta A, Fratini L (2021) Geometrical deviation of end-of-life parts as a consequence of reshaping by single point incremental forming. Int J Adv Manuf Technol 115(5):1579–1588

Ingarao G, Zaheer O, Fratini L (2021) Manufacturing processes as material and energy efficiency strategies enablers: the case of single point incremental forming to reshape end-of-life metal components. CIRP J Manuf Sci Technol 32:145–153

McAnulty T, Jeswiet J, Doolan M (2017) Formability in single point incremental forming: a comparative analysis of the state of the art. CIRP J Manuf Sci Technol 16:43–54

Malhotra R, Xue L, Belytschko T, Cao J (2012) Mechanics of fracture in single point incremental forming. J Mater Process Technol 212:1573–1590

Silva MB, Nielsen PS, Bay N, Martins PAF (2011) Failure mechanisms in single-point incremental forming of metals. Int J Adv Manuf Technol 56(9–12):893–903

Cui Z, Cedric XZ, Ren F, Kiridena V, Gao L (2013) Modeling and validation of deformation process for incremental sheet forming. J Manuf Process 15(2):236–241

Li Y, Liu Z, Lu H, Daniel WB, Liu S, Meehan PA (2014) Efficient force prediction for incremental sheet forming and experimental validation. Int J Adv Manuf Technol 73(1–4):571–587

Bansal A, Lingam R, Yadav SK, Venkata RN (2017) Prediction of forming forces in single point incremental forming. J Manuf Process 28:486–493

Micari F, Ambrogio G, Filice L (2007) Shape and dimensional accuracy in single point incremental forming: state of the art and future trends. J Mater Process Technol 191(1–3):390–395

Najm SM, Paniti I (2021) Artificial neural network for modeling and investigating the effects of forming tool characteristics on the accuracy and formability of thin aluminum alloy blanks when using SPIF. Int J Adv Manuf Technol 114(9):2591–3261

Wang C, He A, Weegink KJ, Liu S, Meehan PA (2020) 3D surface representation and trajectory optimization with a learning-based adaptive model predictive controller in incremental forming. J Manuf Process 58:796–810

Duflou JR, Habraken AM, Cao J, Malhotra R, Bambach M, Adams D, Vanhove H, Amirahmad MA, Jeswiet J (2018) Single point incremental forming: state-of-the-art and prospects. IntJ Mater Form 11:743–773

Lora FA, Fritzen D, Alves De Sousa RJ (2021) Studying formability limits by combining conventional and incremental sheet forming process. Chin J Mech Eng 2021:34. https://doi.org/10.1186/s10033-021-00562-7

Jeswiet J, Young D (2005) Forming limit diagrams for single-point incremental forming of aluminum sheet. Proc Inst Mech Engrs Part B J Eng Manuf 219:359–364

Ingarao G, Di Lorenzo R, Micari F (2009) Analysis of stamping performances of dual phase steels: a multi-objective approach to reduce springback and thinning failure. Mater Des 30(10):4421–4433

Evans M (2009) Minitab manual. W H Freeman, New York

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214(8):1557–1565

Jawale K, Duarte JF, Reisa A, Silva MB (2018) Characterizing fracture forming limit and shear fracture forming limit for sheet metals. J Mater Process Technol 255:886–897

Soeiro JMC, Silva CMA, Silva MB, Martins PAF (2015) Revisiting the formability limits by fracture in sheet metal forming. J Mater Process Technol 217:184–192

Silva MB, Nielsen PS, Bay N, Martins PAF (2011) Failure mechanisms in single-point incremental forming of metals. Int J Adv Manuf Technol 56(9):893–903

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors disclose any financial and non-financial competing interest that could inappropriately influence, or be perceived to influence, this work.

Ethical approval

The authors disclose potential conflicts of interest; also, the research here presented does not involve neither human participants nor animals.

Additional information

Technical editor: Lincoln Cardoso Brandao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zaheer, O., Ingarao, G., Di Lorenzo, R. et al. Study of the implementation of SPIF as a Reshaping strategy in terms of formability and accuracy performance. J Braz. Soc. Mech. Sci. Eng. 44, 467 (2022). https://doi.org/10.1007/s40430-022-03779-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03779-2