Abstract

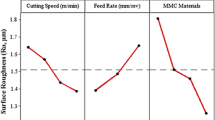

In this study, hybrid composite materials with Al 6061 matrix, boron carbide (B4C) and graphene nanoplate (GNP) being reinforced in different ratios were produced with the stir casting method. Afterward, machinability tests were carried out on the hybrid composites produced with the turning method. SNMG 12 04 08 NN LT 10 coded cutting tools were used in turning experiments. Experiments were realized at a fixed cutting depth of 1 mm, in dry machining conditions, using three different cutting speeds and three different feed rates. In the machinability tests, cutting forces and surface roughness values have been measured. At the same time, microscope images of the cutting tool tips were taken. When the data obtained as a result of the experiments were evaluated, it was observed that the cutting forces increased with the increase in the cutting speed, but the surface roughness values decreased to some extent. While the cutting forces increased with the increase in feed rate, there were no significant differences in roughness values and tool wear amounts. It was determined that the most effective parameter on cutting forces, surface roughness values and tool wear were constituted of the changes in B4C reinforcement ratio. It has been observed that the B4C reinforcement phase significantly increases tool wear. Besides, it was evaluated that GNP supplementation had a positive effect on machinability in some machining parameters and showed dry lubricant properties. It was concluded that the porosity and aggregation of the reinforcement element in the composite structure had a negative effect on the machinability properties. In addition, it was evaluated that it would be appropriate to use non-traditional manufacturing methods in addition to conventional machining processes in the processing of highly B4C reinforced composites.

Similar content being viewed by others

References

Shoba CH, Ramanaiah N, Nageswara Rao D (2017) Effect of reinforcement on the cutting forces while machining metal matrix compositese: an experimental approach. Eng Sci Technol Int J 18:658–663. https://doi.org/10.1016/j.jestch.2015.03.013

Nas E, Gökkaya H (2017) Experimental and statistical study on machinability of the composite materials with metal matrix Al/B4C/graphite. Metall Mater Trans 48A:5059–5067. https://doi.org/10.1007/s11661-017-4237-0

Anthony Xavior M, Ajith Kumar JP (2017) Machinability of hybrid metal matrix composite—a review. Procedia Eng 174:1110–1118. https://doi.org/10.1016/j.proeng.2017.01.26

Anshuman Srivastava A (2017) Recent advances in metal matrix composites (MMCs): a review. Biomed J Sci Tech Res 1(2):1–3. https://doi.org/10.26717/BJSTR.2017.01.000236

Thirumalai Kumaran S, Uthayakumar M (2014) Investigation on the machining studies of AA6351-SiC-B4C hybrid metal matrix composites. Int J Mach Mach Mater 15(3/4):174–185. https://doi.org/10.1504/IJMMM.2014.060548

Kala H, Mer KKS, Kumar S (2014) A review on mechanical and tribological behaviors of stir cast aluminum matrix composites. Procedia Mat Sci 6:1951–1960. https://doi.org/10.1016/j.mspro.2014.07.229

Rebba B, Ramanaiah N (2014) Studies on mechanical properties of 2024 Al-B4C composites. Adv Mater Manuf Charact 4(1):42–46. https://doi.org/10.11127/ijammc.2014.03.06

Kumar Sharma D, Sharma M, Upadhyay G (2019) Boron Carbide (B4C) Reinforced Aluminum Matrix Composites (AMCs). Int J Innov Technol Explor Eng 9(1):2194–2203. https://doi.org/10.35940/ijitee.A4766.119119

Niu Z, Cheng K (2019) Investigation on the material removal and surface roughness in ultraprecision machining of Al/B4C/50p metal matrix composites. Int J Adv Manuf Technol 105:2815–2831. https://doi.org/10.1007/s00170-019-04553-w

Nicholls CJ, Boswell B, Davies IJ, Islam N (2017) Review of machining metal matrix composites. Int J Adv Manuf Technol 90:2429–2441. https://doi.org/10.1007/s00170-016-9558-4

Karabulut Ş, Karakoç H, Çıtak R (2016) Influence of B4C particle reinforcement on mechanical and machining properties of Al6061/B4C composites. Compos B 101:87–98. https://doi.org/10.1016/j.compositesb.2016.07.006

Siddesh Kumar NG, Shiva Shankar GS, Basavarajappa S, Suresh R (2017) Some studies on mechanical and machining characteristics of Al2219/nB4C/MoS2 nano-hybrid metal matrix composites. Measurement 107:1–11. https://doi.org/10.1016/j.measurement.2017.05.003

Siddesh Kumar NG, Shiva Shankar GS, Ganesh MN, Vibudha LK (2017) Experimental investigations to study the cutting force and surface roughness during turning of aluminium metal matrix hybrid composites. Mater Today Proc 4(9):9371–9374. https://doi.org/10.1016/j.matpr.2017.06.187

Kannan C, Ramanujam R (2017) Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J Adv Res 8(4):309–319

Sharma VK, Kumar V, Joshi RS (2019) Experimental investigation on effect of RE oxides addition on tribological and mechanical properties of Al-6063 based hybrid composites. Mater Res Express. 6:0865d7. https://doi.org/10.1088/2053-1591/ab2504

Das S, Chandrasekaran M, Samanta S, Kayaroganam P, Davim P (2019) Fabrication and tribological study of AA6061 hybrid metal matrix composites reinforced with SiC/B4C nanoparticles. Ind Lubr Tribol. 71(1):83–89. https://doi.org/10.1108/ILT-05-2018-0166

Hariprasad T, Varatharajan K, Ravi S (2014) Wear characteristics of B4C and Al2O3 reinforced with Al 5083 metal matrix based hybrid composite. Procedia Eng 97:925–929. https://doi.org/10.1016/j.proeng.2014.12.368

Yuvaraj N, Aravindan S, Vipin, (2017) Wear characteristics of Al5083 surface hybrid nano-composites by friction stir processing. Trans Indian Inst Met 70(4):1111–1129. https://doi.org/10.1007/s12666-016-0905-9

Şenel CM, Gürbüz M, Koç E (2015) New generation composites with graphene reinforced aluminum matrix. J Eng Mach 56(669):36–47

Dharsan K, Santhosh Kumar S (2017) An Exploration of the influence in aluminium metal matrix composite reinforced with graphene. Int J Innov Res Sci Eng Technol 6(7):141–142

Md Ali A, Omar MZ, Hashim H, Salleh MS, Mohamed IF (2021) Recent development in graphene-reinforced aluminium matrix composite: a review. Rev Adv Mater Sci 60:801–817. https://doi.org/10.1515/rams-2021-0062

Li M, Gao H, Liang J, Gu S, You W, Shu D, Wang J, Sun B (2018) Microstructure evolution and properties of graphene nanoplatelets reinforced aluminum matrix composites. Mater Charact 140:172–178. https://doi.org/10.1016/j.matchar.2018.04.007

Joel J, Anthony Xavior M (2018) Machinability analysis of aluminum alloy-graphene metal matrix composites using uncoated and dlc-coated carbide insert. Int Mech Eng Congr Expos ASME 2017. https://doi.org/10.1115/IMECE2017-70098

Khan M, Din RU, Basit MA, Wadood A, Husain SW, Akhtar S, Aune RE (2021) Study of microstructure and mechanical behaviour of aluminium alloy hybrid composite with boron carbide and graphene nanoplatelets. Mater Chem Phys 271:124936. https://doi.org/10.1016/j.matchemphys.2021.124936

Abdelatty R, Khan A, Yusuf M, Alashraf A, Shakoor RA (2021) Article effect of silicon nitride and graphene nanoplatelets on the properties of aluminum metal matrix composites. Materials 14(8):1898. https://doi.org/10.3390/ma14081898

Basavarajappa S, Paulo Davim J (2013) Influence of graphite particles on surface roughness and chip formation studies in turning metal matrix composites. Mater Res 16(5):990–996. https://doi.org/10.1590/S1516-14392013005000098

Ajithkumar JP, Anthony Xavior M (2019) cutting force and surface roughness analysis during turning of Al 7075 based hybrid composites. Procedia Manuf 30:180–187. https://doi.org/10.1016/j.promfg.2019.02.026

Na HB, Xu LH, Han GC, Liu SK, Lu LH (2019) Machinability research on the micro-milling for graphene nano-flakes reinforced aluminum alloy. Metals 9(10):1102. https://doi.org/10.3390/met9101102

Joel J, Anthony Xavior M (2019) Optimization on machining parameters of aluminium alloy hybrid composite using carbide insert. Mater Res Express 6(11):116532. https://doi.org/10.1088/2053-1591/ab46c7

Montoya-Dávila M, Pech-Canul MA, Pech-Canul MI (2007) Effect of bi-and trimodal size distribution on the superficial hardness of al/sicp composites prepared by pressureless infiltration. Powder Technol 176:66–71. https://doi.org/10.1016/j.powtec.2007.02.008

Sur G, Şahin Y, Gökkaya H (2005) Production of aluminum based particulate reinforced composites using molten metal mixing and squeeze casting methods. J Fac Eng Arch Gazi Univ 20(2):233–238

Manna A, Bhattacharyya B (2003) A study on machinability ofAl/SiCMMC. J Mater Process Technol 140(1–3):711–716. https://doi.org/10.1016/S0924-0136(03)00905-1

Lin JT, Bhattacharyya B, Kecman D (2003) Multiple regression and neural networks analyses in composites machining. Compos Sci Technol 63(3–4):539–548. https://doi.org/10.1016/S0266-3538(02)00232-4

Venkatesan K, Ramanujam R, Joel J, Jeyapandiarajan P, Vignesh M, Tolia DJ, Venkata Krishna R (2014) Study of cutting force and surface roughness in machining of Al alloy hybrid composite and optimized using response surface methodology. Procedia Eng 97:677–686. https://doi.org/10.1016/j.proeng.2014.12.297

Verma N, Vettivel SC, Rao PS, Zafar S (2019) Processing tool wear measurement using machine vision system and optimization of machining parameters of boron carbide and rice husk ash reinforced AA 7075 hybrid composite. Mater Res Express 6(8):865f3. https://doi.org/10.1088/2053-1591/ab2509

Hameed Najem S (2013) Machinability of Al-2024 reinforced with Al2O3 and/or B4C. Univ Babylon J 21:84–96

Kannan S, Kishawy HA (2008) Tribological aspects of machining aluminium metal matrix composites. J Mater Process Technol 198:399–406. https://doi.org/10.1016/j.jmatprotec.2007.07.021

Kılıçkap E, Çakır O, Aksoy M, İnan A (2005) Study of tool wear and surface roughness in machining of homogenised SiC-p reinforced aluminium metal matrix composite. J Mater Process Technol 164–165:862–867. https://doi.org/10.1016/j.jmatprotec.2005.02.109

Özcatalbaş Y (2003) Chip and built-up edge formation in the machining of in situ Al4C3–Al composite. Mater Des 24(3):215–221. https://doi.org/10.1016/S0261-3069(02)00146-2

Gökkaya H, Nalbant M (2007) Investigating the effects of cutting speeds over the built-up layer and built-up edge formation with SEM. J Fac Eng Arch Gazi Univ 22(3):481–488

Ajithkumar JP, Anthony Xavior M (2019) Flank and crater wear analysis during turning of Al 7075 based hybrid composites. Mater Res Express 6:086560. https://doi.org/10.1088/2053-1591/ab196e

Na HB, Xu LH, Han GC, Liu SK, Lu LH (2019) Machinability research on the micro-milling for graphene nano-flakes reinforced aluminum alloy. Metals 9:1102. https://doi.org/10.3390/met9101102

Akgün M, Demir H (2021) Experimental and numerical analysis of the effect of cutting parameters on cutting force and chip formation in turning process. El-Cezeri 8(2):897–908. https://doi.org/10.31202/ecjse.892705

Memiş F, Turgut Y (2020) Experimental ınvestigation of surface roughness and cutting forces in machining of AISI 2205 duplex stainless steel on CNC lathe. Manuf Technol Appl 1(1):22–33

Dhand V, Rhee KY, Kim HJ, Jung DH (2013) A comprehensive review of graphene nanocmposites: research satatus and trends. J Nanomater 763953:1–14. https://doi.org/10.1155/2013/763953

Chen LY, Konishi H, Fehrenbacher A, Ma C, Xu JQ, Choi H, Xu HF, Pfeferkorn FE, Li XC (2012) Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scripta Mater 67(1):29–32. https://doi.org/10.1016/j.scriptamat.2012.03.013

Bastwros M, Kim GY, Zhang CZK, Wang S, Tang X (2014) Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos Part: B 60:111–118. https://doi.org/10.1016/j.compositesb.2013.12.043

Bartolucci SF, Paras J, Rafiee MA, Rafiee J, Lee S, Kapoor D, Koratkar N (2011) Graphene-aluminum nanocomposites. Mater Sci Eng A 528(27):7933–7937. https://doi.org/10.1016/j.msea.2011.07.043

Pérez-Bustamante R, Bolaños-Morales D, BonillaMartínez J, Estrada-Guel I, Martínez-Sánchez R (2014) Microstructural and hardness behavior of graphene-nanoplatelets/aluminum composites synthesized by mechanical alloying. J Alloy Compd 615(1):578–582. https://doi.org/10.1016/j.jallcom.2014.01.225

Wang J, Li Z, Fan G, Pan H, Chen Z, Zhang D (2012) Reinforcement with graphene nanosheets in aluminium matrix composites. Scripta Mater 66(8):594–597. https://doi.org/10.1016/j.scriptamat.2012.01.012

Pul M (2013) The effect of MgO ratio on surface roughness in Al-MgO composites. Mater Manuf Process 28:963–968. https://doi.org/10.1080/10426914.2012.677907

Sekmen M, Günay M, Şeker U (2015) Effect on formations of built-up edge and built-up layer, surface roughness of cutting speed and rake angle in the machining of aluminum alloys. J Polytech 18(3):141–148. https://doi.org/10.2339/2015.18.3141148

Özlü B, Akgün M, Demir H (2019) Analysis and optimization of effects on surface roughness of cutting parameters on turning of aa6061 alloy. Gazi J Eng Sci 5(2):151–158. https://doi.org/10.30855/gmbd.2019.02.04

Shoba C, Prasad DS, Sucharita A, Abishek M, Koundinya MS (2018) Investigations of surface roughness power consumption, MRR and tool wear while turning hybrid composites. Mater Today Proc 5(8):16565–16574. https://doi.org/10.1016/j.matpr.2018.06.012

Kannan S, Kishawy HA (2008) Tribological aspects of machining aluminium metal matrix composites. J Mater Process Technol 198(1–3):399–406. https://doi.org/10.1016/j.jmatprotec.2007.07.021

Bozkurt S (2019) Investigation of the effects of cutting parameters on geometric tolerances and surface roughness of AA7075 T651 aluminum alloy during the turning process. Dissertation, University of Karabuk, Turkey

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors do not have any financial or any other interests or obligations in the matter of publications of this research manuscript.

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pul, M., Yağmur, S. Examination of the effect of B4C and GNP reinforcements on machinability in the machining of Al 6061 matrix B4C/GNP reinforced hybrid composites. J Braz. Soc. Mech. Sci. Eng. 44, 469 (2022). https://doi.org/10.1007/s40430-022-03776-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03776-5