Abstract

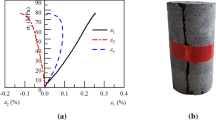

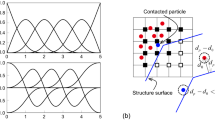

The rock-cutting phenomenon can be considered a challenging problem from a numerical modeling point of view due to the complexity of the physics that comes from the interaction between the rock and the cutter. The present research was aimed at the presentation of a numerical simulation of the rock-cutting process based on the finite element method coupled with smoothed-particle hydrodynamics that was able to provide reasonable estimations of cutting forces for both shallow and deep cuts. Experimental scratch tests on the Vosges sandstone were utilized as modeling targets because all indispensable characteristics of rock cutting were encompassed by these tests. Five well-known material models, namely the soil and foam model (MAT_005), geologic cap model (MAT_025), concrete damage model (MAT_072R3), Johnson and Holmquist concrete model (MAT_111), and continuous surface cap model (MAT_159) in LS-DYNA, were calibrated for Vosges sandstone via the experimental triaxial and hydrostatic compression tests. The calibration process for the determination of the material parameters for each model was discussed in detail. Besides, the accuracy of each model was evaluated in predicting stress–strain behaviors of the rock both in compression and tension under different confining pressures. It was concluded that for Vosges sandstone, the model based on the calibrated parameters of MAT_72R3 is capable of proposing the most robust and reasonable predictions. Moreover, the calibration method can be widely used by occasional users in engineering applications of different types of geomaterials such as concrete, stone, and soil for convenient calibration of constitutive material models.

Similar content being viewed by others

References

Jaime MC, Zhou Y, Lin J-S, Gamwo IK (2015) Finite element modeling of rock cutting and its fragmentation process. Int J Rock Mech Min Sci 80:137–146

Zhou Y, Zhang W, Gamwo I, Lin J-S (2017) Mechanical specific energy versus depth of cut in rock cutting and drilling. Int J Rock Mech Min Sci 100:287–297

Menezes PL (2017) Influence of rock mechanical properties and rake angle on the formation of rock fragments during cutting operation. The Int J Adv Manuf Technol 90:127–139

Menezes PL (2017) Influence of cutter velocity, friction coefficient and rake angle on the formation of discontinuous rock fragments during rock cutting process. Int J Adv Manuf Technol 90:3811–3827

Nishimatsu Y (1972) The mechanics of rock cutting. In: International journal of rock mechanics and mining sciences and geomechanics abstracts. Elsevier, pp 261–270

Molinari A, Moufki A (2008) The Merchant’s model of orthogonal cutting revisited: a new insight into the modeling of chip formation. Int J Mech Sci 50:124–131

Wang Q, Gao S, Jiang B, Li S, He M, Gao H, Qin Q (2018) Rock-cutting mechanics model and its application based on slip-line theory. Int J Geomech 18:04018025

Jiang H, Meng D (2018) 3D numerical modelling of rock fracture with a hybrid finite and cohesive element method. Eng Fract Mech 199:280–293

Menezes PL, Lovell MR, Avdeev IV, Higgs CF III (2014) Studies on the formation of discontinuous rock fragments during cutting operation. Int J Rock Mech Min Sci 71:131–142

Menezes PL, Lovell MR, Avdeev IV, Lin J-S, Higgs CF (2014) Studies on the formation of discontinuous chips during rock cutting using an explicit finite element model. Int J Adv Manuf Technol 70:635–648

Xiao N, Zhou X-P, Gong Q-M (2017) The modelling of rock breakage process by TBM rolling cutters using 3D FEM-SPH coupled method. Tunn Undergr Space Technol 61:90–103

Takabi B, Tajdari M, Tai BL (2017) Numerical study of smoothed particle hydrodynamics method in orthogonal cutting simulations-effects of damage criteria and particle density. J Manuf Process 30:523–531

Jiang H, Liu Z, Gao K (2017) Numerical simulation on rock fragmentation by discontinuous water-jet using coupled SPH/FEA method. Powder Technol 312:248–259

Mardalizad A, Saksala T, Manes A, Giglio M (2020) Numerical modeling of the tool-rock penetration process using FEM coupled with SPH technique. J Petrol Sci Eng 189:107008

Richard T (1999) Determination of rock strength from cutting tests. University of Minnesota

Chaput E (1991) Observations and analysis of hard rocks cutting failure mechanisms using PDC cutters. Ph.D. Thesis, Imperial College, London

Nicodeme P (1997) Transition between ductile and brittle mode in rock cutting. Rapport de stage d’Option Scientifique, Ecole Polytechnique

Zhou Y, Lin J-S (2013) On the critical failure mode transition depth for rock cutting. Int J Rock Mech Min Sci 62:131–137

Cho J-W, Jeon S, Yu S-H, Chang S-H (2010) Optimum spacing of TBM disc cutters: a numerical simulation using the three-dimensional dynamic fracturing method. Tunn Undergr Space Technol 25:230–244

Xia Y, Guo B, Cong G, Zhang X, Zeng G (2017) Numerical simulation of rock fragmentation induced by a single TBM disc cutter close to a side free surface. Int J Rock Mech Min Sci 91:40–48

Liu S, Ni H, Wang X, Wang P, Li N (2020) Numerical study of the compound vertical and horizontal impact cutting with a single PDC cutter. Energy Rep 6:1520–1527

Aquelet N, Souli M, Gabrys J, Olovson L (2003) A new ALE formulation for sloshing analysis. Struct Eng Mech 16:423–440

Souli MH, Ouahsine A, Lewin L (2000) ALE formulation for fluid–structure interaction problems. Comput Methods Appl Mech Eng 190:659–675

Raczy A, Elmadagli M, Altenhof W, Alpas A (2004) An Eulerian finite-element model for determination of deformation state of a copper subjected to orthogonal cutting. Metall Mater Trans A 35:2393–2400

Holmquist TJ, Johnson GR, Cook WH (1993) A computational constitutive model for concrete subjected to large strains, high strain rates, and high pressures. In: Proceeding of 14th international symposium on ballistics, Quebec, Canada, pp 591–600

Malvar L, Crawford J, Wesevich J, Simons D (1994) A new concrete material model for DYNA3D. In: Proceedings, 10th ASCE engineering mechanics conference, pp 142–146

Malvar L, Crawford J, Wesevich J, Simons D (1996) A new concrete material model for DYNA3D release II: shear dilation and directional rate enhancements, a report to Defense Nuclear Agency under Contract No DNA001-91-C-0059

Malvar LJ, Crawford JE, Wesevich JW, Simons D (1997) A plasticity concrete material model for DYNA3D. Int J Impact Eng 19:847–873

Riedel W, Thoma K, Hiermaier S, Schmolinske E (1999) Penetration of reinforced concrete by BETA-B-500 numerical analysis using a new macroscopic concrete model for hydrocodes. In: Proceedings of the 9th international symposium on the effects of munitions with structures, Berlin-Strausberg Germany

Malvar L, Crawford J, Morrill K (2000) K&C concrete material model release III-automated generation of material model input. Karagozian and case structural engineers, Technical Report TR-99-24.3

Murray YD (2007) Users manual for LS-DYNA concrete material model 159, in United States. Federal Highway Administration. Office of Research, Development, and Technology

Murray YD, Abu-Odeh AY, Bligh RP (2007) Evaluation of LS-DYNA concrete material model 159, in, United States. Federal Highway Administration. Office of Research, Development, and Technology

Xu H, Wen H (2016) A computational constitutive model for concrete subjected to dynamic loadings. Int J Impact Eng 91:116–125

Schei G, Fjær E, Detournay E, Kenter C, Fuh G, Zausa F (2000) The scratch test: an attractive technique for determining strength and elastic properties of sedimentary rocks. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers

Bésuelle P, Desrues J, Raynaud S (2000) Experimental characterisation of the localisation phenomenon inside a Vosges sandstone in a triaxial cell. Int J Rock Mech Min Sci 37:1223–1237

Isenberg J, Vaughan D, Sandler I (1978) Nonlinear soil-structure interaction. Final Report Weidlinger Associates

Tu Z, Lu Y (2009) Evaluation of typical concrete material models used in hydrocodes for high dynamic response simulations. Int J Impact Eng 36:132–146

Zhang G, Xiao C (2016) Experimental researches on friction coefficient for disc cutters. Int J Simul Syst Sci Technol 17:1911–1917

Wu C, Koishi M, Hu W (2015) A displacement smoothing induced strain gradient stabilization for the meshfree Galerkin nodal integration method. Comput Mech 56:19–37

Wu C, Hu W, Koishi M (2016) A smoothed particle galerkin formulation for extreme material flow analysis in bulk forming applications. Int J Comput Methods 13:1650019

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Togay Ozbakkaloglu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rokhy, H., Mostofi, T.M. & Ozbakkaloglu, T. Calibration of different constitutive material models for Vosges sandstone due to its application in rock-cutting processes. J Braz. Soc. Mech. Sci. Eng. 44, 468 (2022). https://doi.org/10.1007/s40430-022-03764-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03764-9