Abstract

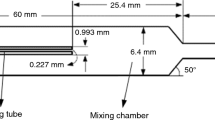

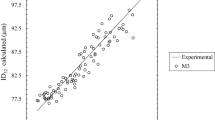

This research consists in the development of a frozen core-annular flow model to estimate the physical variables of the fluids at the exit orifice of the effervescent atomizer. The model is validated through experimental results of the mean thickness of the ligaments, obtaining excellent estimates for GLR ≥ 1.0%. The model is used to simulate five operating conditions in 17 effervescent atomizers. The results obtained show that the geometric variables defining the atomizer design have no significant influence on the estimated physical variables. The estimated physical variables are: (a) gas volume fraction, (b) dimensionless two-phase pressure, (c) dimensionless gas temperature, (d) dimensionless two-phase density, (e) liquid velocity, (f) gas velocity, and (g) liquid thickness. The ranges for the velocity and thickness of the liquid are [7.976, 26.892 m/s] and [165, 641 µm], respectively. Finally, a dimensionless model is established to estimate the integral Sauter mean diameter (ID32) of the spray droplets. The dimensionless model is characterized by having R2 = 0.734 and RMSE = 3.165, so it is considered good for making future predictions.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- \(\overline{c}_{{\text{v,L}}}\) :

-

Mean specific heat at constant volume for the liquid (kJ/(kg*K))

- \(\overline{c}_{{\text{p,G}}}\) :

-

Mean specific heat at constant pressure for the gas (kJ/(kg*K))

- d :

-

Diameter (mm)

- e :

-

Number of exit orifices of atomizer (–)

- E :

-

Energy transfer (kJ)

- g :

-

Gravity acceleration (m/s2)

- GLR:

-

Mass ratio of gas and liquid flow rates (–)

- h :

-

Specific enthalpy (kJ/kg)

- ID32 :

-

Integral Sauter mean diameter (µm)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- \(\overrightarrow {n}\) :

-

Unit normal vector for the control surface

- N :

-

Scalar or vector quantity in relation to the entire control volume

- p :

-

Polytropic index (–)

- P :

-

Absolute pressure (Pa)

- P Atm :

-

Atmospheric pressure (Pa)

- \(\dot{Q}\) :

-

Total volumetric flow rate (m3/s)

- \(\dot{q}\) :

-

Volumetric flow rate in a specific exit orifice of atomizer (m3/s)

- Re:

-

Reynolds number (–)

- R G :

-

Gas constant (kPa*m3/(kg*K))

- S :

-

Surface

- sr:

-

Slip ratio (–)

- T :

-

Temperature (K)

- t :

-

Time (s)

- u :

-

Specific internal energy (kJ/kg)

- \(\overrightarrow {V}\) :

-

Velocity vector

- V :

-

Velocity scalar (m/s)

- \(\overline{V}\) :

-

Mean velocity (m/s)

- We:

-

Weber number (–)

- η :

-

Variable for studying a scalar or vector quantity (N) in the control volume

- ρ :

-

Density (kg/m3)

- α :

-

Volume fraction (–)

- β :

-

Kinetic energy coefficient (–)

- γ :

-

Liquid surface tension (kg/s2)

- µ :

-

Viscosity (kg/(m*s))

- π P :

-

Ratio of the pressure in a position to the pressure in the storage tank (–)

- π T :

-

Ratio of the temperature in a position to the temperature in the storage tank (–)

- π ρ :

-

Ratio of the density in a position to the density of the two-phase mixture using the densities in their respective storage tanks (–)

- ∀ :

-

In the context of the use of the Reynolds transport theorem, it expresses volume, and in the context of some condition for a certain determined variable, it has the meaning of the logical symbol ∀

- e Thi :

-

Thickness of the liquid in the atomizer exit orifice (µm)

- L:

-

Refers to the liquid

- LT:

-

Refers to the liquid storage tank

- P,L:

-

Refers to the pressure of the liquid

- T,L:

-

Refers to the temperature of the liquid

- L,k :

-

Refers to liquid at the exit orifice number “k” of atomizer

- L,exi:

-

Refers to liquid in the exit orifice of the core-annular flow

- P,L,exi:

-

Refers to the liquid pressure in the exit orifice of the core-annular flow

- T,L,exi:

-

L,exi: Refers to the liquid temperature in the exit orifice of the core-annular flow

- G:

-

Refers to the gas

- GT:

-

Refers to the gas storage tank

- P,G:

-

Refers to the pressure of the gas

- T,G:

-

Refers to the temperature of the gas

- G,k :

-

Refers to gas at the exit orifice number “k” of atomizer

- G,exi:

-

Refers to gas in the exit orifice of the core-annular flow

- P,G,exi:

-

Refers to the gas pressure in the exit orifice of the core-annular flow

- T,G,exi:

-

Refers to the gas temperature in the exit orifice of the core-annular flow

- P,exi:

-

Refers to the pressure in the exit orifice of the core-annular flow

- Heat:

-

Refers to the transfer of energy by heat

- Work:

-

Refers to the transfer of energy by shaft work

- i:

-

Refers to the diameter of the interface

- i,ato:

-

Refers to the diameter of the interface for any exit orifice of the atomizer

- i,exi:

-

Refers to the diameter of the interface at the exit orifice of the core-annular flow

- i,k :

-

Refers to the diameter of the interface at the exit orifice number “k” of the atomizer

- o:

-

Refers to the largest diameter transversal to the core-annular flow

- o,ato:

-

Refers to the exit diameter for any exit orifice of the atomizer

- o,exi:

-

Refers to the exit diameter in the exit orifice of the core-annular flow

- o,k :

-

Refers to the exit diameter in the exit orifice number “k” of the atomizer

- T:

-

Refers to the storage tank

- T-P:

-

Refers to two-phase flow

References

Lefebvre AH, McDonell VG (2017) Atomization and sprays, 2nd edn. CRC Press, Boca Raton

Williams A (1990) Combustion of liquid fuel sprays, 1st edn. Butterworth & Co, Oxford

Sirignano WA (2010) Fluid dynamics and transport of droplets and sprays, 2nd edn. Cambridge University Press, Cambridge

Sazhin S (2014) Droplets and sprays, 1st edn. Springer, London

Ashgriz N (2011) Handbook of atomization and sprays, 1st edn. Springer, New York

Basu S, Agarwal AK, Mukhopadhyay A, Patel C (2018) Droplets and sprays, 1st edn. Springer, Singapore

Nasr GG, Yule AJ, Bendig L (2002) Industrial sprays and atomization, 1st edn. Springer, London

Lefebvre AH, Wang XF, Martin CA (1988) Spray characteristics of aerated-liquid pressure atomizers. J Propuls Power 4:293–298

Chin JS, Lefebvre AH (1995) A design procedure for effervescent atomizers. J Eng Gas Turbines Power 117:266–271

Sovani SD, Sojka PE, Lefebvre AH (2001) Effervescent atomization. Prog Energy Combust Sci 27:483–521

Panchagnula MV, Sojka PE, Santangelo PJ (1996) On the three-dimensional instability of a swirling, annular, inviscid liquid sheet subject to unequal gas velocities. Phys Fluids 8:3300–3312

Panchagnula MV, Sojka PE (1999) Spatial droplet velocity and size profiles in effervescent atomizer-produced sprays. Fuel 78:729–741

Lund MT, Sojka PE, Lefebvre AH, Gosselin PG (1993) Effervescent atomization at low mass flow rates. Part I: the influence of surface tension. At Sprays 3:77–89

Lund MT, Jian CQ, Sojka PE et al (1998) The influence of atomizing gas molecular weight on low mass flowrate effervescent atomizer performance. J Fluids Eng Trans ASME 120:750–754

Jedelsky J, Jicha M (2013) Energy conversion during effervescent atomization. Fuel 111:836–844

Mlkvik M, Zaremba M, Jedelsky J, Jicha M (2016) Comparison of Y-jet and OIL effervescent atomizers based on internal and external two-phase flow characteristics. EPJ Web Conf 114:02078

Jicha M, Jedelsky J, Otahal J, Slama J (2002) Influence of some geometrical parameters on the characteristics of effervescent atomization. In: 18th Annual conference on liquid atomization and spray systems. ILASS—Europe, Zaragoza—Spain, p 6

Jedelsky J, Jicha M (2006) Unsteadiness in effervescent sprays—measurement and evaluation using combined PIV—PLIF technique. In: 13th Int symposium on applications of laser techniques to fluid mechanics. Lisbon, Portugal, pp 1–10

Jedelsky J, Otahal J, Jicha M (2007) Effervescent atomizer: influence of the internal geometry on atomization performance. In: Proceedings of the 21th ILASS—Europe meeting. ILASS—Europe, Mugla, Turkey, pp 1–6

Roesler TC, Lefebvre AH (1989) Studies on aerated-liquid atomization. Int J Turbo Jet Engines 6:221–230

Lefebvre AH (1992) Twin-fluid atomization: factors influencing mean drop size. At Sprays 2:101–119

Buckner HN, Sojka PE (1991) Effervescent atomization of high-viscosity fluids: Part I. Newtonian liquids. At Sprays 1:239–252

Buckner HN, Sojka PE (1993) Effervescent atomization of high-viscosity fluids: Part II. Non-Newtonian liquids. At Sprays 3:157–170

Sutherland JJ, Sojka PE, Plesniak MW (1997) Ligament-controlled effervescent atomization. At Sprays 7:383–406

Xiong H-B, Lin J-Z, Zhu Z-F (2009) Three-dimensional simulation of effervescent atomization spray. At Sprays 19:75–90

Konstantinov D, Marsh R, Bowen P, Crayford A (2010) Effervescent atomization for industrial energy-technology review. At Sprays 20:525–552

Wang XF, Chin JS, Lefebvre AH (1989) Influence of gas-injector geometry on atomization performance of aerated-liquid nozzles. Int J Turbo Jet Engines 6:271–279

Otahal J, Fiser J, Jicha M (2007) Performance of pressure and effervescent atomizers. In: Colloquium fluid dynamics 2007. Institute of Thermomechanics AS CR, Prague, Czech Republic, pp 1–7

Broniarz-Press L, Ochowiak M, Woziwodzki S (2010) Atomization of PEO aqueous solutions in effervescent atomizers. Int J Heat Fluid Flow 31:651–658

Ochowiak M, Broniarz-Press L, Rozanska S, Rozanski J (2012) The effect of extensional viscosity on the effervescent atomization of polyacrylamide solutions. J Ind Eng Chem 18:2028–2035

Ochowiak M (2012) The effervescent atomization of oil-in-water emulsions. Chem Eng Process Process Intensif 52:92–101

Ochowiak M (2016) Discharge coefficient of effervescent atomizers with the swirl motion phenomenon. Exp Therm Fluid Sci 79:44–51

Ochowiak M, Broniarz-Press L, Rozanska S et al (2015) Characteristics of spray angle for effervescent-swirl atomizers. Chem Eng Process Process Intensif 98:52–59

Ochowiak M (2013) The experimental study on the viscosity effect on the discharge coefficient for effervescent atomizers. Exp Therm Fluid Sci 50:187–192

Jedelsky J, Jicha M, Slama J, Otahal J (2009) Development of an effervescent atomizer for industrial burners. Energy Fuels 23:6121–6130

Jedelsky J, Landsmann M, Jicha M, Kuritka I (2008) Effervescent atomizer: influence of the operation conditions and internal geometry on spray structure; study using PIV-PLIF. In: 29th European—conference liquid atomization and spray systems. ILASS—Europe, Como Lake, Italy, pp 1–8

Kourmatzis A, Lowe A, Masri AR (2017) Conditioned analysis of effervescent atomization. J Energy Eng 143:1–8

Landau LD, Lifshitz EM (1987) Fluid mechanics, 2nd edn. Pergamon Books, Oxford

Brennen CE (2005) Fundamentals of multiphase flows, 1st edn. Cambridge University Press, Cambridge

Çengel YA, Cimbala JM (2014) Fluid Mechanics, 3rd edn. McGraw Hill, New York

Kourmatzis A, Lowe A, Masri AR (2016) Combined effervescent and airblast atomization of a liquid jet. Exp Therm Fluid Sci 75:66–76

Çengel YA, Boles MA, Kanoğlu M (2019) Thermodynamics: an engineering approach, 9th edn. McGraw-Hill Education, New York

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Erick Franklin.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amaro, J., Mendiburu, A.Z., dos Santos, L.R. et al. Frozen core-annular flow model for effervescent atomizer. J Braz. Soc. Mech. Sci. Eng. 44, 452 (2022). https://doi.org/10.1007/s40430-022-03681-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03681-x