Abstract

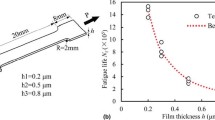

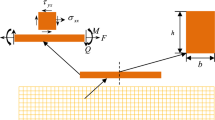

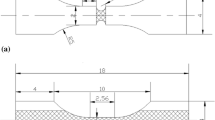

A damage model and simulation strategy are developed to simulate fatigue damage evolution and predict fatigue life of metallic films. The fatigue damage model is established based on the collective effect of current all micro/nanoscale cracks within material in a homogenized way, and block cycle jump method is used in the simulation strategy, which can speed up fatigue damage evolution simulation for metallic films reasonably. Based on numerical study, fatigue damage evolution and life of the smooth and notched specimens for copper films subjected to various stress levels are numerically analyzed and compared with the corresponding experimental results. It shows that the developed damage model and simulation strategy can be used to simulate the fatigue damage evolution and predict fatigue life for metallic films reasonably.

Similar content being viewed by others

Abbreviations

- D :

-

Damage variable

- L :

-

Size of the representative volume element (RVE)

- d :

-

Size of the micro-scale element

- a :

-

Crack length

- A, \(\alpha\) :

-

Model parameters

- \(\Delta \tilde{\sigma }\) :

-

Effective stress range

- \(\Delta \sigma\) :

-

Nominal stress range

- \(N\) :

-

Current cyclic number

- \(\Delta N\) :

-

Cyclic number within one standard loading block

- \(N_{f}\) :

-

Fatigue life

- \(\sigma_{ij}\) :

-

Stress components

- \(\varepsilon_{kl}\) :

-

Strain components

- \(\Delta \sigma\) :

-

Stress range

- \(\delta\) :

-

Kronecker delta

- \(C_{ijkl}\) :

-

Elastic constants

- \(E\) :

-

Initial elastic modulus

- \(v\) :

-

Poisson’s ratio

References

Su Y, Wang S, Huang YA et al (2015) Elasticity of fractal inspired interconnects. Small 11(3):367–373

Sun B, Li Z (2019) Kinematics analysis of scissor-type inspired interconnects. Acta Mech 230(8):2979–2988

Sun B, Li Z (2019) An efficient computational method for curved interconnects deformation. Eur J Mech-A/Solids 75:82–92

Gleskova H, Cheng IC, Wagner S et al (2006) Mechanics of thin-film transistors and solar cells on flexible substrates. Sol Energy 80(6):687–693

Song YM, Xie Y, Malyarchuk V et al (2013) Digital cameras with designs inspired by the arthropod eye. Nature 497(7447):95

Kim J, Lee M, Shim HJ et al (2014) Stretchable silicon nanoribbon electronics for skin prosthesis. Nat Commun 5:5747

Lee D, Lee J, Kim T et al (2019) Effect of the thermal annealing on the stretchability and fatigue failure of the copper film on the polymer substrate. J Electron Mater 48(7):4582–4588

Tripathi PN, Ojha SK, Nazarov A (2020) Development of highly reliable BiFeO3/HfO2/Silicon gate stacks for ferroelectric non-volatile memories in IoT applications. J Mater Sci: Mater Electron 31(24):22107–22118

Sodavaram NK, Arif KM (2019) Fatigue testing of integrated thin film metal membranes for implantable biomedical pressure sensors. J Mech Sci Technol 33(7):3383–3389

Bizouerne M, Pargon E, Petitetienne C et al (2018) Low damage patterning of In0.53Ga0.47As film for its integration as n-channel in a fin metal oxide semiconductor field effect transistor architecture. J Vacuum Sci Technol 36(6):061305

Kim BJ, Jung SY, Cho Y et al (2013) Crack nucleation during mechanical fatigue in thin metal films on flexible substrates. Acta Mater 61(9):3473–3481

Lee S, Yoo T, Han Y et al (2017) Polyimide-epoxy composites with superior bendable properties for application in flexible electronics. J Electron Mater 46(8):1–10

Schnabl K, Wentlent L, Mootoo K et al (2014) Nanocopper based solder-free electronic assembly. J Electron Mater 43(12):4515–4521

Zhu S, Hao Y, Liao D et al (2020) Probabilistic modeling and simulation of multiple surface crack propagation and coalescence. Appl Math Model 78:383–398

Liao D, Zhu S, Correia JA et al (2020) Recent advances on notch effects in metal fatigue: a review. Fatigue Fract Eng Mater Struct 43(4):637–659

Kraft O, Schwaiger R, Wellner P (2001) Fatigue in thin films: lifetime and damage formation. Mater Sci Eng, A 319:919–923

Wimmer A, Heinz W, Detzel T et al (2015) Cyclic bending experiments on free-standing Cu micron lines observed by electron backscatter diffraction. Acta Mater 83:460–469

Zhang GP, Sun KH, Zhang B et al (2008) Tensile and fatigue strength of ultrathin copper films. Mater Sci Eng, A 483:387–390

Kondo T, Bi XC, Hirakata H et al (2016) Mechanics of fatigue crack initiation in submicron-thick freestanding copper films. Int J Fatigue 82:12–28

Ostrowicki GT, Sitaraman SK (2016) Cyclic magnetic actuation technique for thin film interfacial fatigue crack propagation. Eng Fract Mech 168:1–10

Kondo T, Hirakata H, Minoshima K (2017) Thickness effects on fatigue crack propagation in submicrometer-thick freestanding copper films. Int J Fatigue 103:444–455

Kondo T, Shin A, Akasaka M, Hirakata H, Minoshima K (2019) Vacuum effects on fatigue crack growth in submicrometre-thick freestanding copper films. Fatigue Fract. Eng. Mater. Struct. 42(5):1118–1129

Liu XD, Shang DG, Li M et al (2013) Healing fatigue damage by laser shock peening for copper film. Int J Fatigue 54:127–132

Lee DY, Song JH (2012) Fatigue life and plastic deformation behavior of electrodeposited copper thin film under variable amplitude loading. Int J Fatigue 38:1–6

Samet D, Rambhatla VNNT, Kwatra A et al (2017) A fatigue crack propagation model with resistance curve effects for an epoxy/copper interface. Eng Fract Mech 180:60–72

Zhang B, Xiao TY, Luo XM et al (2015) Enhancing fatigue cracking resistance of nanocrystalline Cu films on a flexible substrate. Mater Sci Eng, A 627:61–64

Sun B, Li Z (2014) A multi-scale damage model for fatigue accumulation due to short cracks nucleation and growth. Eng Fract Mech 127:280–295

Sun B, Xu YL, Li Z (2016) Multi-scale fatigue model and image-based simulation of collective short cracks evolution process. Comput Mater Sci 117:24–32

Sun B, Xu YL, Li Z (2016) Multi-scale model for linking collective behavior of short and long cracks to continuous average fatigue damage. Eng Fract Mech 157:141–153

Kondo T, Shin A, Hirakata H et al (2016) Fatigue crack propagation properties of submicron-thick freestanding copper films in vacuum environment. Procedia Struct Integr 2:1359–1366

Lemaitre J (2012) A course on damage mechanics. Springer, London

Sun B (2018) A continuum model for damage evolution simulation of the high strength bridge wires due to corrosion fatigue. J Constr Steel Res 146:76–83

Sun B, Xu YL, Wang FY et al (2019) Multi-scale fatigue damage prognosis for long-span steel bridges under vehicle loading. Struct Infrastruct Eng 15:524–538

Fish J, Yu Q (2002) Computational mechanics of fatigue and life predictions for composite materials and structures. Comput Methods Appl Mech Eng 191:4827–4849

Sun B, Xu YL, Zhu Q et al (2019) Auto-adaptive multiblock cycle jump algorithm for fatigue damage simulation of long-span steel bridges. Fatigue Fract Eng Mater Struct 42(4):919–928

Sun B, Xu YL, Zhu Q et al (2019) Concurrent multi-scale fatigue damage evolution simulation method for long-span steel bridges. Int J Damage Mech 28(2):165–182

Liu H, Shang DG, Ma XP et al (2009) Tension-tension fatigue properties and life prediction of electroplated copper films. J Mech Eng 45(9):261–265

Acknowledgements

The works described in this paper are financially supported by National Program on Key Research and Development Project of China (2020YFB2103500-2) and National Natural Science Foundation of China (grant no. 52008104), to which the authors are most grateful.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no conflict of interest in the manuscript.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, B. A model and simulation strategy for fatigue damage evolution of copper films. J Braz. Soc. Mech. Sci. Eng. 43, 276 (2021). https://doi.org/10.1007/s40430-021-02996-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02996-5