Abstract

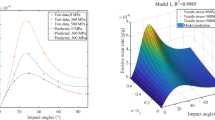

A finite element model was built to assess the combined effects of internal pressure and axial applied stress\(\left( {\sigma_{A} } \right)\) on localized stress concentration and electrochemical corrosion at defects on pipelines under the mechano-electrochemical (M-E) interaction. When defect angle \(\alpha\) (i.e., included angle between the major axis of the defect and longitudinal direction of the pipe) is 90°, the maximum stress of the defect is enlarged remarkably with the increase in \(\sigma_{A}\), leading to electrochemical corrosion at the defect affected greatly under the M-E interaction. However, when \(\alpha\) is 0°, the maximum stress and electrochemical corrosion are affected slightly by the \(\sigma_{A}\). Besides, when the hoop stress of the pipe is larger than its total axial stress, the largest corrosion rate at the defect with \(\alpha\) of 0° would be higher than that at the defect with \(\alpha\) of 90°. Thus, for the improvement of pipeline integrity management, the combined effects of internal pressure and \(\sigma_{A}\) should be taken into account for a more accurate prediction of local corrosion rate at the defect especially with \(\alpha\) of 90°.

Similar content being viewed by others

References

Xu LY, Cheng YF (2012) Corrosion of X100 pipeline steel under plastic strain in a neutral pH bicarbonate solution. Corros Sci 64:145–152. https://doi.org/10.1016/j.corsci.2012.07.012

Yajima A, Wang H, Liang RY, Castaneda H (2015) A clustering based method to evaluate soil corrosivity for pipeline external integrity management. Int J Pres Ves Pip 126:37–47. https://doi.org/10.1016/j.ijpvp.2014.12.004

Liu HW, Cheng YF (2017) Mechanism of microbiologically influenced corrosion of X52 pipeline steel in a wet soil containing sulfate-reduced bacteria. Electrochim Acta 253:368–378. https://doi.org/10.1016/j.electacta.2017.09.089

Dai MJ, Liu J, Huang F, Zhang YH, Cheng YF (2018) Effect of cathodic protection potential fluctuations on pitting corrosion of X100 pipeline steel in acidic soil environment. Corros Sci 143:428–437. https://doi.org/10.1016/j.corsci.2018.08.040

Lu YX, Jing HY, Han YD, Xu LY (2018) A finite element model of carbon steel welded joint corrosion under plastic strain. Mater Corros 69:227–238. https://doi.org/10.1002/maco.201709620

Gutman EM (1998) Mechanochemistry of materials. Cambridge Interscience Publishing, Cambridge

Wang HT, Han EH (2013) Simulation of metastable corrosion pit development under mechanical stress. Electrochim Acta 90:128–134. https://doi.org/10.1016/j.electacta.2012.11.056

Xu LY, Cheng YF (2017) A finite element based model for prediction of corrosion defect growth on pipelines. Int J Pres Ves Pip 153:70–79. https://doi.org/10.1016/j.ijpvp.2017.05.002

Fatoba OO, Leiva-Garcia R, Lishchuk SV, Larrosa NO, Akid R (2018) Simulation of stress-assisted localised corrosion using a cellular automaton finite element approach. Corros Sci 137:83–97. https://doi.org/10.1016/j.corsci.2018.03.029

González-Arévalo NE, Velázquez JC, Díaz-Cruz M, Cervantes-Tobón A, Terán G, Hernández-Sanchez E, Capula-Colindres S (2021) Influence of aging steel on pipeline burst pressure prediction and its impact on failure probability estimation. Eng Fail Anal 120:104950. https://doi.org/10.1016/j.engfailanal.2020.104950

Shuai Y, Shuai J, Xu K (2017) Probabilistic analysis of corroded pipelines based on a new failure pressure model. J Eng Fail Anal 81:216–233. https://doi.org/10.1016/j.engfailanal.2017.06.050

Noda NA, Hayashida H (2000) Interaction between elliptical and ellipsoidal inclusions under bending stress fields. Arch Appl Mech 70:612–624. https://doi.org/10.1007/s004190000093

Kishawy HA, Gabbar HA (2010) Review of pipeline integrity management practices. Int J Pres Ves Pip 87:373–380. https://doi.org/10.1016/j.ijpvp.2010.04.003

Meliani MH, Matvienko YG, Pluvinage G (2011) Corrosion defect assessment on pipes using limit analysis and notch fracture mechanics. Eng Fail Anal 18:271–283. https://doi.org/10.1016/j.engfailanal.2010.09.006

Sun JL, Cheng YF (2018) Assessment by finite element modeling of the interaction of multiple corrosion defects and the effect on failure pressure of corroded pipelines. Eng Struct 165:278–286. https://doi.org/10.1016/j.engstruct.2018.03.040

Sun JL, Cheng YF (2019) Investigation by numerical modeling of the mechano-electrochemical interaction of circumferentially aligned corrosion defects on pipelines. Thin Walled Struct 144:106314. https://doi.org/10.1016/j.tws.2019.106314

Xu LY, Cheng YF (2012) An experimental investigation of corrosion of X100 pipeline steel under uniaxial elastic stress in a near-neutral pH solution. Corros Sci 59:103–111. https://doi.org/10.1016/j.corsci.2012.02.022

Xu LY, Cheng YF (2013) Development of a finite element model for simulation and prediction of mechanoelectrochemical effect of pipeline corrosion. Corros Sci 73:150–160. https://doi.org/10.1016/j.corsci.2013.04.004

Kim YJ, Son BG (2004) Finite element based stress concentration factors for pipes with local wall thinning. Int J Pres Ves Pip 81:897–906. https://doi.org/10.1016/j.ijpvp.2004.06.002

Ji J, Zhang CS, Kodikara J, Yang SQ (2015) Prediction of stress concentration factor of corrosion pits on buried pipes by least squares support vector machine. Eng Fail Anal 55:131–138. https://doi.org/10.1016/j.engfailanal.2015.05.010

Zhang J, Liang Z, Han CJ (2015) Effects of ellipsoidal corrosion defects on failure pressure of corroded pipelines based on finite element analysis. Int J Electrochem Sci 10:5036–5047

Adib H, Jallouf S, Schmitt C, Carmasol A, Pluvinage G (2007) Evaluation of the effect of corrosion defects on the structural integrity of X52 gas pipelines using the SINTAP procedure and notch theory. Int J Pres Ves Pip 84:123–131. https://doi.org/10.1016/j.ijpvp.2006.10.005

Demofontim G, Mannucci G, Hillenbrand HG, Harris D (2004) Evaluation of the suitability of X100 steel pipes for high pressure gas transportation pipelines by full scale tests. Paper presented at the international pipeline conference, Calgary, Alberta, Canada, October 4–8

Chouchaoui BA, Pick RJ (1996) Behaviour of longitudinally aligned corrosion pits. Int J Pres Ves Pip 67:17–35. https://doi.org/10.1016/0308-0161(94)00057-3

ASME B31.4 (2009) Pipeline transportation systems for liquid hydrocarbons and other liquids. The American Society of Mechanical Engineers, New York

Park JJ, Pyun SI, Na KH, Lee SM, Kho YT (2002) Effect of passivity of the oxide film on low-pH stress corrosion cracking of API 5L X-65 pipeline steel in bicarbonate solution. Corros 58:329–336. https://doi.org/10.5006/1.3287682

Liu B, Liu XJ, Zhang H (2009) Strain-based design criteria of pipelines. J Loss Prev Process Ind 22:884–888. https://doi.org/10.1016/j.jlp.2009.07.010

Bagotsky VS (2006) Fundamentals of electrochemistry, 2nd edn. John Wiley and Sons Inc

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Chen, S. Finite element modeling of local corrosion accelerated by the mechano-electrochemical coupling effect at defects on pipelines under combined effects of internal pressure and axial applied stress. J Braz. Soc. Mech. Sci. Eng. 43, 269 (2021). https://doi.org/10.1007/s40430-021-02990-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02990-x