Abstract

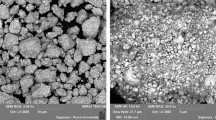

The laser remelting technique is considered a promising and effective method for improving the surface of thermally sprayed coatings, eliminating microstructural defects such as pores and cracks, increasing the life of parts and equipment by increasing microhardness and increasing anchoring force between coating and substrate. In the present work, tungsten carbide alloy (WC–12Co–4Cr) coatings were deposited on properly prepared SAE 1016 substrates using the high velocity oxy-fuel technique. An ytterbium fiber laser was used to remelt the surface of the coating by accurately varying the scanning speed and laser beam power to achieve a pore and crack-free coating and better metallurgical anchorage to the substrate through the optimization of the studied parameters. The samples were characterized by scanning electron microscopy and microhardness. The results show that it is possible to obtain higher hardness coatings after the laser remelting process, free of pores or pronounced imperfections and metallurgically bonded to the substrate. We also found a processing range for the ytterbium laser remelting of the WC–12Co–4Cr coating aiming at high productivity and microstructural optimization of the coating for different thicknesses.

Similar content being viewed by others

References

Masuku ZH, Olubambi PA, Potgieter JH, Obadele BA (2015) Tribological and corrosion behavior of HVOF-sprayed WC–Co-based composite coatings in simulated mine water environments. Tribol Trans 58(2):337–348

La Barbera-Sosa JG, Santana Y, Caro J, Chicot D, Lesage J, Staia MH, Puchi-Cabrera ES (2014) Mechanical properties of WC coatings evaluated using instrumented indentation technique. Surf Eng 30(7):498–510

Hong S, Wu YP, Gao WW, Wang B, Guo WM, Lin JR (2014) Microstructural characterisation and microhardness distribution of HVOF sprayed WC–10Co–4Cr coating. Surf Eng 30(1):53–58

Pokhmurska A, Ciach R (2000) Microstructure and properties of laser treated arc sprayed and plasma sprayed coatings. Surf Coat Technol 125(1–3):415–418

Uyulgan B, Dokumaci E, Celik E, Kayatekin I, Azem N, Ozdemir I, Toparli M (2007) Wear behaviour of thermal flame sprayed FeCr coatings on plain carbon steel substrate. J Mater Process Technol 190(1–3):204–210

Matikainen V, Bolelli G, Koivuluoto H, Sassatelli P, Lusvarghi L, Vuoristo P (2017) Sliding wear behaviour of HVOF and HVAF sprayed Cr3C2-based coatings. Wear 388:57–71

Das B, Gopinath M, Nath AK, Bandyopadhyay PP (2018) Effect of cooling rate on residual stress and mechanical properties of laser remelted ceramic coating. J Eur Ceram Soc 38(11):3932–3944

Hou GL, An YL, Zhao XQ, Chen J, Chen JM, Zhou HD, Liu G (2012) Effect of heat treatment on wear behaviour of WC–(W, Cr)2C–Ni coating. Surf Eng 28(10):786–790

Mateen A, Saha GC, Khan TI, Khalid FA (2011) Tribological behaviour of HVOF sprayed near-nanostructured and microstructured WC-17wt.% Co coatings. Surf Coat Technol 206(6):1077–1084

Hazra S, Das J, Bandyopadhyay PP (2015) Synthesis of mullite-based coatings from alumina and zircon powder mixtures by plasma spraying and laser remelting. Mater Chem Phys 154:22–29

Zhou S, Xu Y, Liao B, Sun Y, Dai X, Yang J, Li Z (2018) Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding. Opt Laser Technol 103:8–16

Vostřák M, Tesař J, Houdková Š, Smazalová E, Hruška M (2017) Diagnostic of laser remelting of HVOF sprayed Stellite coatings using an infrared camera. Surf Coat Technol 318:360–364

Rakhes M, Koroleva E, Liu Z (2011) Improvement of corrosion performance of HVOF MMC coatings by laser surface treatment. Surf Eng 10:729–733

Dejun K, Tianyuan S (2017) Wear behaviors of HVOF sprayed WC–12Co coatings by laser remelting under lubricated condition. Opt Laser Technol 89:86–91

Cui C, Ye F, Song G (2012) Laser surface remelting of Fe-based alloy coatings deposited by HVOF. Surf Coat Technol 206(8–9):2388–2395

Ciubotariu CR, Frunzăverde D, Mărginean G, Șerban VA, Bîrdeanu AV (2016) Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Opt Laser Technol 77:98–103

Astarita A, Genna S, Leone C, Minutolo FMC, Rubino F, Squillace A (2015) Study of the laser remelting of a cold sprayed titanium layer. Procedia CIRP 33:452–457

Kang N, Verdy C, Coddet P, Xie Y, Fu Y, Liao H, Coddet C (2017) Effects of laser remelting process on the microstructure, roughness and microhardness of in situ cold sprayed hypoeutectic Al–Si coating. Surf Coat Technol 318:355–359

Cai Z, Cui X, Liu Z, Li Y, Dong M, Jin G (2018) Microstructure and wear resistance of laser cladded Ni–Cr–Co–Ti–V high-entropy alloy coating after laser remelting processing. Opt Laser Technol 99:276–281

Li Y, Dong S, Yan S, Liu X, Li E, He P, Xu B (2019) Elimination of voids by laser remelting during laser cladding Ni based alloy on gray cast iron. Opt Laser Technol 112:30–38

Yu J, Wang Y, Zhou F, Wang L, Pan Z (2018) Laser remelting of plasma-sprayed nanostructured Al2O3–20 wt.% ZrO2 coatings onto 316L stainless steel. Appl Surf Sci 431:112–121

Panziera RC, Flores WH, Tier MAD, de Oliveira ACC (2019) Comparison of abrasive wear by rice husk of an HVOF WC–Co–Cr-based coating and an electric arc sprayed coating based on Fe–Cr–B–Si. J Braz Soc Mech Sci Eng 41(8):331

Muvvala G, Karmakar DP, Nath AK (2017) Online monitoring of thermo-cycles and its correlation with microstructure in laser cladding of nickel based super alloy. Opt Lasers Eng 88:139–152

Scendo M, Trela J, Radek N (2014) Influence of laser power on the corrosive resistance of WC–Cu coating. Surf Coat Technol 259:401–407

Houdková Š, Pala Z, Smazalová E, Vostřák M, Česánek Z (2017) Microstructure and sliding wear properties of HVOF sprayed, laser remelted and laser clad Stellite 6 coatings. Surf Coat Technol 318:129–141

Dong S, Wang Y, Zeng J, Yang X, Liang P, Wang D et al (2019) Performance of plasma-sprayed CuNiIn coatings and Mo coatings subjected to fretting fatigue. Nano Mater Sci. https://doi.org/10.1016/j.nanoms.2019.07.003

Gisario A, Puopolo M, Venettacci S, Veniali F (2015) Improvement of thermally sprayed WC–Co/NiCr coatings by surface laser processing. Int J Refract Metal Hard Mater 52:123–130

de Sousa JMS, Ratusznei F, Pereira M, de Medeiros Castro R, Curi EIM (2020) Abrasion resistance of Ni–Cr–B–Si coating deposited by laser cladding process. Tribol Int 143:106002

Li R, Li Z, Huang J, Zhu Y (2012) Dilution effect on the formation of amorphous phase in the laser cladded Ni–Fe–B–Si–Nb coatings after laser remelting process. Appl Surf Sci 258(20):7956–7961

Acknowledgements

The authors thank the company Rijeza Metalurgia, Brazil, for the production of tungsten carbide coating. Precision Mechanics Laboratory—LMP, Department of Mechanical Engineering—EMC, Federal University of Santa Catarina—UFSC and Federal University of Pampa—UNIPAMPA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Izabel Fernanda Machado, Dr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Panziera, R.C., de Oliveira, A.C.C., Pereira, M. et al. Study of the effects of the laser remelting process on the microstructure and properties of the WC–10Co–4Cr coating sprayed by HVOF. J Braz. Soc. Mech. Sci. Eng. 42, 119 (2020). https://doi.org/10.1007/s40430-020-2201-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-2201-1