Abstract

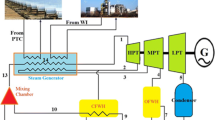

This article presents a novel and applied solution for increasing the efficiency and cost-effectiveness of waste-fired power plants and comprehensively analyzes the proposal from thermodynamic, economic, and environmental aspects. The idea is centered around the simultaneous use of passive (flue gas condensation) and active (solar thermal heaters comprising evacuated tube collectors and parabolic trough collectors) for feedwater preheating. In this way, the extracted heat from the turbines for this purpose could be used directly for power generation, and thus, higher waste-to-power efficiency of the cycle. The proposed configuration and the base-case power plant are both simulated in TRNSYS software for dynamic modeling and comparison of the results over an entire year of operation of the power plants. For making the results more reliable for real-life operation conditions, the simulations are run for a real case study in Qassim city, Saudi Arabia. The results of exergy analysis show that the waste incinerator with the annual exergy destruction of 128.3 GWh is the main source of irreversibility in both models. The results further indicate that the proposed novel system is the more suitable option with 11.36 GWh and 68.18 GWh more annual produced electricity and heat, respectively. With these numbers, although the unit product cost of the proposed novel system is 2.2 $/MWh higher than the conventional plant due to the high cost of solar systems, the new system results in a 205.08 ton/GWh lower CO2 emission index which is extremely important and even of high economic value preventing large emission taxes.

Similar content being viewed by others

Abbreviations

- c:

-

CHP product unit cost ($/GJ)

- Ċ:

-

Cost rate ($/h)

- Ė:

-

Electricity (kWh)

- Ėx:

-

Exergy rate (kWh)

- ir :

-

Interest rate

- LHV:

-

Lower heating value (kJ/kg)

- ṁ :

-

Mass flow rate (kg/s)

- P:

-

Pressure (kPa)

- \(\dot{Q}\) :

-

Heat rate (kWh)

- T:

-

Temperature (°C)

- V:

-

Volume (m3)

- x:

-

Extracted ratio of first preheating line

- y:

-

Extracted ratio of second preheating line

- Z:

-

Purchased cost ($)

- Ż:

-

Investment cost rate ($/hr

- CI:

-

CI

- COND:

-

COND

- CFWH:

-

CFWH

- CHP:

-

Combined heating and power

- CRF:

-

CRF

- D:

-

Destruction

- eco:

-

Economizer

- eva:

-

Evaporator

- ETC:

-

Evacuated tube collector

- HPT:

-

High-pressure turbine

- IPT:

-

Intermediate pressure turbine

- L:

-

Loss

- lm:

-

Logarithmic mean

- LPT:

-

Low-pressure turbine

- WI:

-

Waste incinerator

- MSW:

-

Municipal solid waste

- OFWH:

-

Open feedwater heater

- OM:

-

Operation and maintenance

- ORC:

-

Organic Rankine cycle

- P:

-

Product

- PTC:

-

Parabolic trough collector

- SG:

-

Steam generator

- WI:

-

Waste incinerator

- \({\upeta }_{{{\text{II}}}}\) :

-

Exergy efficiency

- \({\upeta }_{{\text{I}}}\) :

-

Energy efficiency

- \({\upeta }_{{{\text{is}}}}\) :

-

Isentropic efficiency

References

Alsagri AS, Arabkoohsar A, Milad Khosravi AAA (2019) Efficient and cost-effective district heating system with decentralizedheat storage units, and triple-pipes. Energy. https://doi.org/10.1016/j.energy.2019.116035

Taghizadeh A, Taghizadeh M, Azimi M, Alsagri AS, Alrobaian AA, Afrand M (2020) Influence of cerium oxide nanoparticles on thermal conductivity of antifreeze: preparation and stability of nanofluid using surfactant. J Therm Anal Calorim 139:225–236. https://doi.org/10.1007/s10973-019-08422-2

Alsagri AS, Arabkoohsar A, Rahbari HR, Alrobaian AA (2019) Partial load operation analysis of trigeneration subcooled compressed air energy storage system. J Clean Prod 238:117948. https://doi.org/10.1016/j.jclepro.2019.117948

Hosseini SS, Mehrpooya M, Alsagri AS, Alrobaian AA (2019) Introducing, evaluation and exergetic performance assessment of a novel hybrid system composed of MCFC, methanol synthesis process, and a combined power cycle. Energy Convers Manag 197:111878. https://doi.org/10.1016/j.enconman.2019.111878

Alrobaian AA, Alsagri AS, Ali JA, Hamad SM, Shafee A, Nguyen TK et al (2019) Investigation of convective nanomaterial flow and exergy drop considering CVFEM within a porous tank. J Therm Anal Calorim 139(3):2337–2350. https://doi.org/10.1007/s10973-019-08564-3

Elminshawy NAS, Mohamed AMI, Morad K, Elhenawy Y, Alrobaian AA (2019) Performance of PV panel coupled with geothermal air cooling system subjected to hot climatic. Appl Therm Eng 148:1–9. https://doi.org/10.1016/j.applthermaleng.2018.11.027

Alrobaian AA (2020) Improving waste incineration CHP plant efficiency by waste heat recovery for feedwater preheating process: energy, exergy, and economic (3E) analysis. J Braz Soc Mech Sci Eng 42:1–14. https://doi.org/10.1007/s40430-020-02460-w

Arabkoohsar A, Rahrabi HR, Alsagri AS, Alrobaian AA (2020) Impact of Off-design operation on the effectiveness of a low-temperature compressed air energy storage system. Energy 197:117176. https://doi.org/10.1016/j.energy.2020.117176

Alsagri AS, Chiasson A, Gadalla M (2019) Viability assessment of a concentrated solar power tower with a supercritical Co2 Brayton cycle power plant. J Sol Energy Eng 141:51006–51015

Behzadi A, Arabkoohsar A (2020) Comparative performance assessment of a novel cogeneration solar-driven building energy system integrating with various district heating designs. Energy Convers Manag 220:113101. https://doi.org/10.1016/j.enconman.2020.113101

Alrobaian A, Rajasekar V, Alagumalai A (2020) Critical insight into biowaste-derived biocatalyst for biodiesel production. Environ Prog Sustain Energy. https://doi.org/10.1002/ep.13391

Alrobaian AA, Alturki AS (2020) Investigation of numerical and optimization method in the new concept of solar panel cooling under the variable condition using nanofluid. J Therm Anal Calorim. https://doi.org/10.1007/s10973-019-09174-9

Alsagri AS, Arabkoohsar A, Alrobaian AA (2019) Combination of subcooled compressed air energy storage system with an organic Rankine cycle for better electricity efficiency, a thermodynamic analysis. J Clean Prod 239:118119. https://doi.org/10.1016/j.jclepro.2019.118119

Behzadi A, Gholamian E, Houshfar E, Habibollahzade A (2018) Multi-objective optimization and exergoeconomic analysis of waste heat recovery from Tehran’s waste-to-energy plant integrated with an ORC unit. Energy 160:1055–1068. https://doi.org/10.1016/j.energy.2018.07.074

Jannatkhah J, Najafi B, Ghaebi H (2020) Energy and exergy analysis of combined ORC—ERC system for biodiesel-fed diesel engine waste heat recovery. Energy Convers Manag 209:112658. https://doi.org/10.1016/j.enconman.2020.112658

Feng Y, Du Z, Shreka M, Zhu Y, Zhou S, Zhang W (2020) Thermodynamic analysis and performance optimization of the supercritical carbon dioxide Brayton cycle combined with the Kalina cycle for waste heat recovery from a marine low-speed diesel engine. Energy Convers Manag 206:112483. https://doi.org/10.1016/j.enconman.2020.112483

Neshat E, Asghari M (2020) Investigation on the effect of reformer gas on availability terms and waste heat recovery from exhaust gases of an HCCI engine considering radiation heat transfer. J Braz Soc Mech Sci Eng. https://doi.org/10.1007/s40430-019-2139-3

Yang F, Zhang H, Bei C, Song S, Wang E (2015) Parametric optimization and performance analysis of ORC (organic Rankine cycle) for diesel engine waste heat recovery with a fin-and-tube evaporator. Energy 91:128–141. https://doi.org/10.1016/j.energy.2015.08.034

Nami H, Arabkoohsar A (2019) Improving the power share of waste-driven CHP plants via parallelization with a small-scale Rankine cycle, a thermodynamic analysis. Energy 171:27–36. https://doi.org/10.1016/j.energy.2018.12.168

Mosleh HJ, Hakkaki-fard A, Daqiqshirazi M (2019) A year-round dynamic simulation of a solar combined, ejector cooling, heating and power generation system. Appl Therm Eng 153:1–14. https://doi.org/10.1016/j.applthermaleng.2019.02.114

Shoaib M, Khan A, Waheed A, Talha T, Wajahat M, Sarfraz F (2018) Configuration based modeling and performance analysis of single e ff ect solar absorption cooling system in TRNSYS. Energy Convers Manag 157:351–363. https://doi.org/10.1016/j.enconman.2017.12.024

Calise F, Dentice M, Macaluso A, Vanoli L, Piacentino A (2016) A novel solar-geothermal trigeneration system integrating water desalination : design, dynamic simulation and economic assessment. Energy 115:1533–1547. https://doi.org/10.1016/j.energy.2016.07.103

Ghorbani B, Borzoo K, Mehrpooya M, Hamedi M (2020) Introducing a hybrid renewable energy system for production of power and fresh water using parabolic trough solar collectors and LNG cold energy recovery. Renew Energy 148:1227–1243. https://doi.org/10.1016/j.renene.2019.10.063

El B, Martinez D, Ait R, Cadi E, Ihlal A (2017) Thermal plant based on parabolic trough collectors for industrial process heat generation in Morocco. Renew Energy 113:1261–1275. https://doi.org/10.1016/j.renene.2017.06.063

Ghaith FA, Razzaq H (2017) Performance of solar powered cooling system using parabolic trough collector in UAE. Sustain Energy Technol Assess 23:21–32. https://doi.org/10.1016/j.seta.2017.08.005

Eboh FC, Andersson B-Å (2019) Richards T. Economic evaluation of improvements in a waste-to-energy combined heat and power plant. Waste Manag 100:75–83

Chen H, Zhang M, Xue K, Xu G, Yang Y, Wang Z et al (2020) An innovative waste-to-energy system integrated with a coal-fired power plant. Energy. https://doi.org/10.1016/j.energy.2019.116893

Wisconsin-Madison SK, Station EE (1988) TRNSYS-A transient system simulation program. University of Wisconsin-Madison, Engineering Experiment Station Report, pp.38-12

Behzadi A, Arabkoohsar A, Gholamian E (2020) Multi-criteria optimization of a biomass-fired proton exchange membrane fuel cell integrated with organic Rankine cycle/thermoelectric generator using different gasification agents. Energy 201:117640. https://doi.org/10.1016/j.energy.2020.117640

Behzadi A, Houshfar E, Gholamian E, Ashjaee M, Habibollahzade A (2018) Multi-criteria optimization and comparative performance analysis of a power plant fed by municipal solid waste using a gasi fi er or digester. Energy Convers Manag 171:863–878. https://doi.org/10.1016/j.enconman.2018.06.014

Elsafi AM (2015) Exergy and exergoeconomic analysis of sustainable direct steam generation solar power plants. Energy Convers Manag 103:338–347

Dincer I, Rosen MA, Ahmadi P (2017) Optimization of energy systems. Wiley, New York

Habibollahzade A, Gholamian E, Houshfar E, Behzadi A (2018) Multi-objective optimization of biomass-based solid oxide fuel cell integrated with stirling engine and electrolyzer. Energy Convers Manag 171(1116):1133. https://doi.org/10.1016/j.enconman.2018.06.061

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Ahmad Arabkoohsar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been selected for a Topical Issue of this journal on Nanoparticles and Passive-Enhancement Methods in Energy.

Rights and permissions

About this article

Cite this article

Alrobaian, A.A. Combination of passive and active enhancement methods for higher efficiency of waste-fired plants; flue gas and solar thermal processing. J Braz. Soc. Mech. Sci. Eng. 42, 607 (2020). https://doi.org/10.1007/s40430-020-02692-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02692-w