Abstract

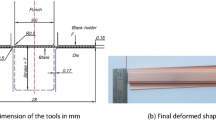

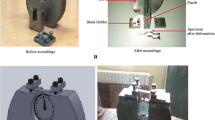

In sheet metal forming, residual stresses are related to springback and material failure after the deformation process or during service due to load history. Thus, being able to either calculate or measure such stresses is of great importance. This paper aims to evaluate the use of the Electronic Speckle Pattern Interferometry (ESPI) technique to measure residual stresses on TRIP steel. Residual stresses are measured after springback on specimens used in three-point bending tests; where three bending angles are considered. Experiments are compared with Finite Element calculations in terms of punch force, springback angle and residual stresses. Work-hardening and anisotropy parameters, used in simulations, are experimentally determined by the uniaxial tensile test. Results indicate that advanced hardening models are necessary to increase the accuracy of springback predictions. Nevertheless, residual stress calculations show a good correlation with experimental values. Also, it was proved that ESPI is a powerful technique to measure the residual stress on complex surfaces, as the ones typically encountered in sheet forming processes. Future work includes residual stress predictions for different forming processes.

Similar content being viewed by others

References

Farsi MA, Arezoo B (2007) Experimental and numerical study on the influence of die width and component material on spring-back and bending force of V-shape dies. In: Proceedings of the TICME2007 conference. Tehran, Iran

Huang YM, Chen T (2005) Influence of blank profile on the V-die bending camber process of sheet metal. Int J Manuf Technol 25:668–677

Vallelano C, Morales D, García-Lomas F (2008) On the study of the effect of bending in the formability of metal sheets. In: Numisheet conference. September 1–5. Interlaken, Switzerland

Kim K, Kimchi M, Altan T (2009) Control of springback in bending and flanging advanced high strength steels (AHSS). in: International automotive body congress (IABC). November 4–5 2009. Troy, Michigan

Kardes N, Mete O, Demiralp Y, Choi C, Altan T (2012) Springback prediction in bending of AHSS-DP780. In: Proceedings of NAMRI/SME, vol 40

Yoshida F, Hamasaki H, Uemori T (2013) A user-friendly 3D yield function to describe anisotropy of steel sheets. Int J Plast 45:119–139

Gotoh M (1977) Theory of plastic anisotropy based on a yield function of 4th order (plane stress state). Int J Mech Sci 19:505–512

Hill R (1948) A theory of yielding and plastic flow of anisotropy metals. Proc R Soc Lond A 193:281–297

Barlat F, Lege DJ, Brem JC (1991) A 6-component yield function for anisotropic materials. Int J Plast 7:693–712

Prager W (1956) A new method of analyzing stresses and strains in work hardening solids. ASME J Appl Mech 78:41–57

Ziegler H (1959) A modification of Prager’s hardening rule. Q Appl Math 17:55–65

Yoshida F, Uemori T, Fujiwara K (2002) Elastic-plastic behavior of steel sheets under in-plane cyclic tension-compression at large strain. Int J Plast 18:633–659

Yoshida F, Uemori T (2002) A model of large-strain cyclic plasticity describing the Bauschinger effect and work-hardening stagnation. Int J Mater Process Technol 18:661–686

Komgrit L (2011) An investigation on effect of residual stress on springback behavior of high strength in U-bending process. Adv Mater Res 189–193:2864–2868

Essa A, Nasr M, Ahmed H (2016) Variation of the residual stress and springback in sheet bending from plane-strain to plane stress condition using finite element modeling. In: 17th International conference on applied mechanics and mechanical engineering, pp 37–49

Kardan M, Parvizi A, Askari A (2018) Influence of process parameters on residual stress in deep-drawing process with FEM and experimental evaluations. J Braz Soc Mech Sci 157:1–12

Standard ASTM (2000) E837-13a. Test method for determining residual stresses by the hole-drilling strain-gage method, ASTM International Materials Park

Ricket T (2016) Residual stress measurement by ESPI hole-drilling. In: 3rd CIRP conference on surface integrity. Procedia CIRP, vol 45, pp 203–206

Ricket T, Fix R (2007) Comparison of residual stress measurements using x-ray diffraction and PRISM-electronic speckle pattern interferometry and hole-drilling. SAE Technical Paper. Berkeley, Cal

Steinzing M, Ponslet E (2003) Residual stress measurement using the hole drilling method and laser speckle interferometry: part I. Experimental techniques. Technol Appl Ser 27:43–46

Steinzing M, Takahashi T (2003) Residual stress measurement using the hole drilling method and laser speckle interferometry: part IV. Experimental techniques. Technol Appl Ser 27:59–63

Sugimoto K et al (1992) Effects of ductility volume fraction and stability of TRIP-aided dual-phase steels. ISIJ Int 32:1311–1318

Galán J et al (2012) Advanced high strength steels for automotive industry. Rev Metal 48:118–131

Standard ASTM (2004) E8-04 standard test methods for tension testing of metallic materials. ASTM International

Hill R (1990) Constitutive modelling of orthotropic plasticity in sheet metals. J Mech Phys Solids 38:405–417

Hill R (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond Ser A Math Phys Sci 193:281–297

Standard ASTM (2013) E290-13 Standard test methods for bend testing of material for ductility. ASTM International

DIN EN ISO 7438 (2005) Metallic materials-bend test

Hu H, Sun X, Golovashchenko S (2016) An integrated finite element-based simulation framework: from hole piercing to hole expansion. Finite Elem Anal Des 109:1–13

Marumo Y, Saiki H (1998) Evaluation of the forming limit of aluminum square cups. J Mater Proc Technol 80–81:427–432

Lee Y, Barlat F, Lee M (2015) Constitutive and friction modeling for accurate springback analysis of advanced high strength steel sheets. Int J Plast 71:113–135

Komgrit L, Hamasaki H, Hino R, Yoshida F (2016) Elimination of springback of high-strength steel sheet by using additional bending with counter punch. J Mater Proc Technol 229:199–206

Hosford W (2005) Mechanical behavior of materials. Waveland Press, Cambridge

Joudaki J, Sedighi M (2015) Effect of material´s behavior on residual stress distribution in elastic-plastic beam bending: an analytical solution. J Mater Des Appl 231:361–372

Schilling R (1994) Sheet bending and determination of residual stress by means of FEM. Steel Res 5:255–291

Acknowledgments

The first author would like to express its gratitude for the financial support of the Mexican government through the “Consejo Nacional de Ciencia y Tecnología” (CONACYT). Also, we would like to thank to the company Pintura, Estampado y Montaje S.A.P.I. de C.V. (PEMSA) for providing the material used for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Díaz-Mendoza, A.E., Capilla-González, G., Martínez-Ramírez, I. et al. Experimental and numerical analysis of the residual stress distribution in a three-point bending test of a TRIP sheet by using ESPI. J Braz. Soc. Mech. Sci. Eng. 42, 544 (2020). https://doi.org/10.1007/s40430-020-02640-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02640-8