Abstract

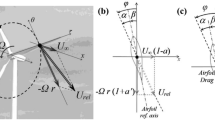

In this paper, a hardware in the loop (HIL) scheme using a polynomial approximation for the calculation of aerodynamic forces associated with wind turbine blades is presented. The proposed approach allows the real-time calculation of forces acting on a blade for use as input data for a force emulating system. The blade element momentum (BEM) theory was used to calculate the axial and tangential forces, but an iterative algorithm needs to be executed for each time of the system’s operation. In order to allow a real-time calculation, the BEM algorithm can be executed for a range of rotor angular speeds, wind velocities, and pitch angles covering the conditions under which the wind turbine will operate. The resulting power, torque, and forces are then approximated by polynomials and implemented in an HIL test facility. A comparison between the results obtained from the BEM algorithm and polynomials demonstrates the accuracy of the proposed approach. An experimental setup comprised of the software used for the force and pitch angle calculation and the hardware used for the force emulation and pitch angle control is presented. Experimental results obtained with the system running in real-time demonstrate the ability to apply effective moments without the need for an extensive test structure.

Similar content being viewed by others

Abbreviations

- α :

-

Angle of attack [rad]

- \(\alpha_{\text{o}}\) :

-

Optimal angle of attack [rad]

- β :

-

Pitch angle [rad]

- β ref :

-

Reference pitch angle [rad]

- β 0 :

-

Optimal twist angle [rad]

- κ :

-

Resultant aerodynamic force angle [rad]

- λ :

-

Specific velocity [1]

- λ r :

-

Local specific velocity [1]

- \(\mu\) :

-

Radius ratio [1]

- \(\mu_{{\rm r}}\) :

-

Bearing friction coefficient [1]

- ρ :

-

Air density [kg/m3]

- \(\rho_{\text{b}}\) :

-

Blade specific mass [kg/m3]

- \(\sigma_{\text{p}}\) :

-

Prandtl correction coefficient [1]

- ʋ :

-

Cinematic viscosity [m2/s]

- ϕ :

-

Total angle [rad]

- ω :

-

Rotor angular velocity [rad/s]

- ω max :

-

Optimal angular velocity [rad/s]

- \(a\) :

-

Axial interference factor [1]

- \(a_{ {\min} }\) :

-

Minimal axial interference factor [1]

- \(a^{\prime }\) :

-

Rotational interference factor [1]

- \(a_{\text{G}}\) :

-

Glauert’s axial interference factor [1]

- A r :

-

Actuator area ration [m2]

- B :

-

Number of blades [1]

- C :

-

Chord distance [m]

- \(C_{\text{D}}\) :

-

Drag coefficient [1]

- \(C_{\text{L}}\) :

-

Lift coefficient [1]

- \(C_{\text{Lo}}\) :

-

Optimal lift coefficient [1]

- \(C_{\text{M}}\) :

-

Moment coefficient [1]

- \(C_{\text{p}}\) :

-

Power coefficient [1]

- \(C_{Tr}\) :

-

Glauert’s coefficient [1]

- \({{\rm d}}F_{\text{a}}\) :

-

Infinitesimal axial force [N]

- \({{\rm d}}F_{\text{D}}\) :

-

Infinitesimal drag force [N]

- \({{\rm d}}F_{{\rm L}}\) :

-

Infinitesimal lift force [N]

- \({{\rm d}}F_{{\rm aMT}}\) :

-

Infinitesimal axial force from Moment Theory [N]

- \({{\rm d}}F_{{\rm CA,B}}\) :

-

Infinitesimal centrifugal force at points A or B [N]

- \({{\rm d}}F_{{\rm CIA,B}}\) :

-

Infinitesimal tangential centrifugal force at points A or B [N]

- \({{\rm d}}F_{{\rm t}}\) :

-

Infinitesimal tangential force [N]

- \({{\rm d}}F_{{\rm R}}\) :

-

Infinitesimal resultant force [N]

- \({{\rm d}}T_{{\rm ae}}\) :

-

Infinitesimal aerodynamic momentum [Nm]

- \(D_{{\rm mB}}\) :

-

Bearing average diameter [m]

- F a :

-

Axial force [N]

- \(F_{{\rm fE}}\) :

-

Actuator emulation system friction force [N]

- F aB :

-

Bearing axial force [N]

- F C ref :

-

Hydraulic compensated reference force [N]

- F C eff :

-

Hydraulic effective force [N]

- F H ref :

-

Hydraulic reference force [N]

- F rB :

-

Bearing radial force [N]

- F ref :

-

Reference force [N]

- F t :

-

Tangential force [N]

- \(I\) :

-

Blade polar inertia [kg m2]

- I max,min :

-

Maximum or minimum moment of inertia [m4]

- I p :

-

Centrifugal moment of inertia [m4]

- L :

-

Length of lever [m]

- m :

-

Blade mass [kg]

- mg :

-

Weight force [N]

- p A :

-

Pressure in the chamber A [Pa]

- p B :

-

Pressure in the chamber B [Pa]

- p S :

-

Hydraulic supply pressure [Pa]

- p T :

-

Hydraulic reservoir pressure [Pa]

- P T :

-

Turbine power [W]

- r :

-

Local blade radius [m]

- r GZ :

-

Distance between mass center and the longitudinal axis [m]

- R :

-

Turbine radius [m]

- R 0 :

-

Minimum effective turbine radius [m]

- Re :

-

Reynolds number [1]

- T a :

-

Axial moment [Nm]

- T ae :

-

Aerodynamic moment [Nm]

- T L :

-

Load moment [Nm]

- T C :

-

Centrifugal moment [Nm]

- T fB :

-

Bearing friction moment [Nm]

- \(T_{{\rm H}}\) :

-

Hydraulic moment [Nm]

- \(T_{{\rm I}}\) :

-

Blade inertia moment [Nm]

- T k :

-

Bearing resultant moment [Nm]

- \(T_{{\rm L}}\) :

-

Load torque [Nm]

- T t :

-

Tangential moment [Nm]

- \(T_{{\rm tB}}\) :

-

Bearing tangential moment [Nm]

- T g :

-

Weight force moment [Nm]

- T gi :

-

Instant weight force moment [Nm]

- v :

-

Wind velocity [m/s]

- v r :

-

Relative wind velocity [m/s]

- y AZ :

-

Distance between attack edge and gravity center [m/s]

- y ZC :

-

Distance between turbine rotational axis and blade gravity center [m]

References

Burton T, Sharpe D, Jenkins N, Bossanyi E (2001) Wind energy handbook. Wiley, Chichester, p 643

Yin X, Lin Y, Li W, Ye H, Gu Y, Liu H (2015) Reproduction of five degree-of-freedom loads for wind turbine using equispaced electro-hydraulic actuators. Renew Energy 83:626–637

Bossanyi EA, Jamieson P (1999) Blade pitch system modelling for wind turbines. In: European wind energy conference, Nice, France, pp 893–896

Yao X, Shan G, Su D (2006) Study on variable pitch system characteristics of big wind turbine. In: Technology and innovation conference, pp 2239–2243

Hansen MH, Kallesoe BS (2007) Servo-elastic dynamics of a hydraulic actuator pitching a blade with large deflections. J Phys Conf Ser 75:1742–6588. https://doi.org/10.1088/1742-6596/75/1/012077

Meisami-Azad M, Grigoriadis KM (2013) Anti-windup linear parameter-varying control of pitch actuators in wind turbines. Wind Energy 18(2):187–200

Juettner M, Hasse A, Tremmel S (2017) Flexure pitch bearing concept for individual pitch control of wind turbines. Wind Energy 21(2):129–138

Gertz D, Johnson DA (2011) An evaluation testbed for wind turbine blade tip designs-baseline case. Int J Energy Res 35(15):1360–1370

Lasheen A, Saad MS, Emara HM, Elshafei AL (2019) Tube-based explicit model predictive output-feedback controller for collective pitching of wind turbines. Renew Energy 139:549–562

Chiang MH (2011) A novel pitch control system for a wind turbine driven by a variable-speed pump-controlled hydraulic servo system. J Mechatron Sci Intell Mach 21:753–761

Caselitz P, Geyler M, Giebhardt J, Panahandeh B (2006) Hardware-in-the-loop development and testing of new pitch control algorithms. In: Proceedings of European wind energy conference (EWEC 2006), Athens, Greece, 27 Feb–2 Mar 2006

Wu X, Li Y, Li F, Yang Z, Teng W (2011) Adaptative estimation based leakage detection for a wind turbine hydraulic pitching system. IEEE Trans Mechatron 17:907–914

Clausen PD, Piddington DM, Wood DH (1987) An experimental investigation of blade element theory for wind turbines. Part 1. Mean flow results. J Wind Eng Ind Aerodyn 25:89–206

Hau E (2005) Wind turbines, fundamentals, technologies, application, economics. Springer, Krailling, p 791

Bianchi F, De Battista H, Mantz RJ (2006) Wind turbine control systems—principles, modelling and gain scheduling design. Advances in industrial control. Springer, London, p 218

Munteanu I, Bratcu AI, Cutululis NA, Ceanga E (2008) Optimal control of wind energy systems, towards a goal approach. Advances in industrial control. Springer, London, p 283

VESTAS (2000) Wind turbines catalog

Manwell JF, Mcgowan JG, Rogers AL (2009) Wind energy explained—theory, design and application, 2nd edn. Wiley, Chichester, p 704

Hansen MH, Hansen A, Larsen TJ, Oye S, Sorensen P, Fuglsang P (2005) Control design for a pitch regulated, variable speed wind turbine. Riso-R Report Riso National Laboratory, Roskilde, Denmark, p 84

Bertagnolio F, Sorensen N, Johansen J, Fuglsang P (2001) Wind turbine airfoil catalogue. Riso National Laboratory, Roskilde, Denmark, p 152

Abbot I, Von Doenhoff A, Stivers L (1945) Summary of airfoil data. National Advisory Committee of Aeronautics, Report No. 824

Gonzalez FE (2012) Study of the forces acting on pitch angle control mechanisms and development of a load emulator system (Estudo das Forças Atuantes em Mecanismos de Regulação de Ângulo de Passo e Desenvolvimento de um Sistema Emulador de Cargas). Master’s Thesis, Federal University of Santa Catarina, Florianópolis

Sun W, Wei Y, Luan S (2010) The design and research of largescale wind turbine blades automatic generation system. In: 3rd international conference on advanced computer theory and engineering

Betz A (1926) Wind-Energie und Ihre Ausnutzung durch Windmühlen. Vandenhoeck & Ruprecht, Göttingen

Dal Monte A, De Betta S, Castelli MR, Benini M (2017) Proposal for a coupled aerodynamic–structural wind turbine blade optimization. Compos Struct 159:144–159

Elgammi M, Sant T, Alshaikh M (2019) Predicting the stochastic aerodynamic loads on blades of two yawed downwind hawts in uncontrolled conditions using a bem algorithm. Renew Energy Int J 146:371–383

Saenz-Aguirre A, Fernandez-Gamiz U, Zulueta E, Aramendia I, Teso-Fz_Betono D (2020) Flow control based 5 MW Wind turbine enhanced energy production for hydrogen generation cost reduction. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2020.01.022

Lekou DJ, Mouzakis F, Savenije FJ (2010) Procedures for testing and measuring wind energy systems. Centre for Renewable Energy Sources and Saving, Pikermi

SKF (1989) Catálogo Geral. Stamperia ARtisitica Nazionale, Italia, p 976, ex 1

Fingerish L, Johnson K (2002) Controls advanced research turbine (CART) commissioning and baseline data collection technical report. National Renewable Energy Laboratory, Colorado, USA, October 2002

Miller NW, Sanchez-Gasca JJ, Price WW, Delmerico RW (2003) Dynamic modeling of GE 1.5 and 3.6 MW wind turbine generators for stability simulations. In: IEEE PES general meeting, Toronto, Canada

Pao LY, Johnson KE (2009) A tutorial on the dynamics and control of wind turbines and wind farms. In: Proceedings of American control conference, St. Louis, MO, June 2009, pp 2076–2089

Dai JC, Hu YP, Liu DS, Long X (2011) Aerodynamic loads calculation and analysis for large scale wind turbine based on combining BEM modified theory with dynamic stall model. Renew Energy 36:1095–1104

Rothe Erde (2011) Slewing bearings. Dortmund, Germany. http://www.rotheerde.com/download/info/Rothe_Erde_GWL_GB.pdf. Accessed 4 Aug 2019

Den Hartog JP (1948) Mechanics. McGraw-Hill, New York, p 472

D’errico J (2011) Polyfitn, polynomial modeling in 1 or n dimensions. Matlab Central File Exchange. http://www.mathworks.com/matlabcentral/fileexchange/34765-polyfitn. Accessed 4 Aug 2019

Destro CM, De Negri VJ (2018) Method for combining valves with symmetric and asymmetric cylinders for hydraulic systems. Int J Fluid Power 19(3):126–139

Acknowledgements

This work was carried out with the support of CAPES (Coordination for the Improvement of Higher Education Personnel), Reivax SA Control and Automation, and CNPq (National Council for Scientific and Technological Development).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Celso Kazuyuki Morooka.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nostrani, M.P., Gonzalez, F.E. & De Negri, V.J. Analysis and emulation of pitch control forces in wind turbines. J Braz. Soc. Mech. Sci. Eng. 42, 262 (2020). https://doi.org/10.1007/s40430-020-02350-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02350-1