Abstract

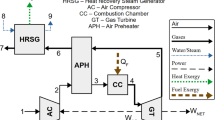

Global energy demand is expected to increase in the following two decades. Operational flexibility of power generation systems is a key aspect when assessing potential solutions seeking to help meeting this expected increase in global energy demand. In low calorific value (LCV) gaseous fuels-fired power plants, it is paramount to consider the effects of the employed LCV/lean-gases-based fuels on the associated gas turbine systems and surrounding equipment. Moreover, because of the industrial processes usually occurring upstream these power plants, the fuel supply conditions change significantly during their normal operation. Gas turbines based on LCV gaseous fuels thus present a quite distinct engine behavior, and their modeling is therefore challenging. The dynamic modeling of such engines is the main focus of this work. Accordingly, the gas turbine dynamic model developed here is initially discussed, along with topics, such as gas turbine mass flow rates, cooling systems effectiveness and gas turbine component characteristics, relevant to the dynamic modeling of LCV fuels-based power plants. The use of the developed model for the simulation of an actual combined cycle power plant with cogeneration based on a LCV fuel is next highlighted. The main results show that overall acceptable agreements between computed parameters and actual power plant operating data are obtained. The corresponding average discrepancies range from 1 to 6%. In spite of the large number of factors directly influencing the numerical results obtained from the real-time simulations carried out, the power plant operating data trends are in general well reproduced by the computed results. The obtained results highlight in particular both the model applicability to operating scenarios presenting significant gradients in gas turbine characteristic parameters, and the need of including in the modeling key processes present in power plants actual operation.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- a :

-

Characteristic parameter, constant (−)

- b :

-

Characteristic parameter, constant (−)

- Cp:

-

Specific heat at constant pressure (kJ/kg K)

- c :

-

Characteristic parameter, constant (−)

- h :

-

Specific enthalpy (kJ/kg)

- \( \hbar \) :

-

Heat transfer (film) coefficient (kW/m2K)

- I :

-

Inertia moment (kg m2)

- k :

-

Characteristic parameter, constant (−)

- M :

-

Mass (kg)

- \( \dot{m} \) :

-

Mass flow rate (kg/s)

- N :

-

Rotational speed (rad/s)

- N * :

-

Non-dimensional speed (−)

- PR:

-

Pressure ratio (−)

- p :

-

Pressure (kPa)

- \( \dot{Q} \) :

-

Heat rate (kW)

- T :

-

Temperature (K)

- t :

-

Time (s)

- U :

-

Heat transfer coefficient (kW/m2 K)

- u :

-

Specific Internal energy (kJ/kg)

- V :

-

Volume (m3)

- \( \dot{W} \) :

-

Power (kW)

- \( \varGamma \) :

-

Characteristic parameter (−)

- \( \Delta \) :

-

Delta (change) (−)

- \( \varepsilon \) :

-

Effectiveness (−)

- \( \eta \) :

-

Efficiency (−)

- \( \rho \) :

-

Density (kg/m3)

- \( \phi \) :

-

Equivalence ratio (−)

- amb:

-

Ambient

- c :

-

Cold side

- cc:

-

Combustion chamber

- db:

-

Dry bulb

- f:

-

Fuel, filter

- h:

-

Hot side

- i:

-

Inlet

- m:

-

Metal

- o:

-

Outlet

- r:

-

Reference

- s:

-

Shaft

- v:

-

Valve

- wb:

-

Wet bulb

- 2:

-

Combustion chamber entry

- 3:

-

Combustion chamber exit

- BFG:

-

Blast furnace gas

- BTU:

-

British thermal unit

- FAR:

-

Fuel-air ratio

- HRSG:

-

Heat recovery steam generator

- IGCC:

-

Integrated gasification combined cycle

- IGV:

-

Inlet guide vane

- ISO:

-

International Organization for Standardization

- LCV:

-

Low calorific value

- LHV:

-

Lower heating value

- OEM:

-

Original equipment manufacturer

- TIT:

-

Turbine inlet temperature

References

World Energy Outlook 2016, International Energy Agency, www.worldenergyoutlook.org

United Nations, Climate Change, The Paris Agreement, http://unfccc.int/paris_agreement/items/9485.php

Kakaras E, Doukelis A, Prelipceanu A, Karellas S (2006) Inlet air cooling methods for gas turbine based power plants. J Eng Gas Turbines Power 128:312–317

Al-Ibrahim AM, Varnham A (2010) A review of inlet air-cooling technologies for enhancing the performance of combustion turbines in Saudi Arabia. Appl Therm Eng 30:1879–1888

Farzaneh-Gord M, Deymi-Dashtebayaz M (2011) Effect of various inlet air cooling methods on gas turbine performance. Energy 36:1196–1205

Sahraei MH, McCalden D, Hughes R, Ricardez-Sandoval LA (2014) A survey on current advanced IGCC power plant technologies, sensors and control systems. Fuel 137:245–259

Tsakomakas NG, Pilavachi PA, Polyzakis AL (2012) An economic comparison assessment of lignite and biomass IGCC power plants. Appl Therm Eng 38:26–30

Modesto M, Nebra SA (2009) Exergoeconomic analysis of the power generation system using blast furnace and coke oven gas in a Brazilian steel mill. Appl Therm Eng 29:2127–2136

Zhou B, Ye H, Zhang H, Li M (2016) Process monitoring of iron-making process in a blast furnace with PCA-based methods. Control Eng Pract 47:1–14

Kim YS, Lee JJ, Kim TS, Sohn JL (2011) Effects of syngas type on the operation and performance of a gas turbine in integrated gasification combined cycle. Energy Convers Manag 52:2262–2271

Rodrigues M, Walter A, Faaij A (2007) Performance evaluation of atmospheric biomass integrated gasifier combined cycle systems under different strategies for the use of low calorific gases. Energy Conver Manag 48:1289–1301

Lee JJ, Kim YS, Cha KS, Kim TS, Sohn JL, Joo YJ (2009) Influence of system integration options on the performance of an integrated gasification combined cycle power plant. Appl Energy 86:1788–1796

Pinto GRS (2015) Avaliação do desempenho de usinas termelétricas a ciclo combinado integradas com gaseificação via integração de programas especialistas, M.Sc. Dissertation, COPPE/Universidade Federal do Rio de Janeiro, RJ, Brazil

Cellier FE, Kofman E (2006) Continuous system simulation. Springer, Berlin

Aminov Z, Nakagoshi N, Xuan TD, Higashi O, Alikulov K (2016) Evaluation of the energy efficiency of combined cycle gas turbine. Case study of Tashkent thermal power plant, Uzbekistan. Appl Therm Eng 103:501–509

Alobaid F, Mertens N, Starkloff R, Lanz T, Heinze C, Epple B (2016) Progress in dynamic simulation of thermal power plants. Prog Energy Combust Sci 59:79–162

Celis C, Pinto GRS, Teixeira T, Xavier E (2017) A steam turbine dynamic model for full scope power plant simulators. Appl Therm Eng 120:593–602

Mehrpanahi A, Payganeh G, Arbabtafti M (2017) Dynamic modeling an industrial gas turbine in loading and unloading condition using a gray box method. Energy 120:1012–1024

Mehrpanahi A, Payganeh G, Arbabtafti M, Hamidavi A (2017) Semi-simplified black-box dynamic modeling of an industrial gas turbine based on real performance characteristics. J Eng Gas Turbines Power 139:121601

Mehrpanahi A, Hamidavi A, Ghorbanifar A (2018) A novel dynamic modeling of an industrial gas turbine using condition monitoring data. Appl Therm Eng 143:507–520

Tsoutsanisa E, Meskinb N (2019) Dynamic performance simulation and control of gas turbines used for hybrid gas/wind energy applications. Appl Therm Eng 147:122–142

Barsali S, De Marco A, Giglioli R, Ludovici G, Possenti A (2015) Dynamic modelling of biomass power plant using micro gas turbine. Renew Energy 80:806–818

Chen M, Zhang Y, Liang Y, Peng D (2012) The application of optimization of gradual steps in blended-fuel power plant. In: Wang FL, Lei J, Lau RWH, Zhang J (eds) Multimedia and signal processing, communications in computer and information science, vol 346. Springer, Berlin, pp 491–498

Song J, Zhang A, Zheng H (2013) Study on dynamic optimization model of surplus gas distribution in iron and steel plant. Adv Mater Res 610–613:2228–2231

Mattos HAS, Bringhenti C, Cavalca DF, Silva OFR, Campos GB, Tomita JT (2016) Combined cycle performance evaluation and dynamic response simulation. J Aerosp Technol Manag 8:491–497

Leyzerovich AS (2008) Steam turbines for modern fossil-fuel power plants. The Fairmont Press, Lilburn

Electric Power Research Institute (EPRI) (1993) Justification of simulators for fossil fuel power plants, Technical Report TR-102690, EPRI, USA

Schobeiri MT, Attia M, Lippke C (1994) GETRAN: a generic, modularly structured computer code for simulation of dynamic behavior of aero- and power generation gas turbine engines. J Eng Gas Turbines Power 116:483–494

Kulikov GG, Thompson HA (eds) (2004) Dynamic modelling of gas turbines—identification, simulation, condition monitoring and optimal control. Springer, London

Kim JH, Song TW, Kim TS (2001) Model development and simulation of transient behavior of heavy duty gas turbines. J Eng Gas Turbines Power 123:589–594

Schobeiri MT (1986) A general computational method for simulation and prediction of transient behavior of gas turbines. In: ASME international gas turbine conference and exhibit, Dusseldorf, Germany

Crosa G, Pittaluga F, Trucco A, Beltrami F, Torelli A, Traverso F (1998) Heavy-duty gas turbine plant aerothermodynamic simulation using simulink. J Eng Gas Turbines Power 120:550–556

Simani S, Fantuzzi C (2006) Dynamic system identification and model-based fault diagnosis of an industrial gas turbine prototype. Mechatronics 16:341–363

Shin JY, Jeon YJ, Maeng DJ, Kim JS, Ro ST (2002) Analysis of the dynamic characteristics of a combined-cycle power plant. Energy 27:1085–1098

Alves, M. A., Transitório não-adiabático de turbinas a gás, PhD Thesis, Instituto Tecnológico de Aeronáutica, Brazil (2003)

Ferreira SB (2002) Thermoeconomic analysis and optimization of biomass fuel gas turbines, Ph.D. Thesis, Cranfield University, UK

Roldan-Villasana EJ, Cardoso-Goroztieta MJ, Tavira-Mondragon JA, Rossano MB (2010) Lumped Parameters modelling of the waterwalls of a power plant steam generator. In: IEEE fourth UKSim European symposium on computer modeling and simulation, Pisa, Italy

Cengel YA, Boles MA (2015) Thermodynamics, an engineering approach, 8th edn. McGraw-Hill Education, New York

Celis C, de Avellar VP, Ferreira SB, Braga SL (2007) Evaluation of different alternatives of power augmentation for an existing combined cycle power plant in Brazil, ASME Turbo Expo 2007: Power for Land, Sea, and Air

Razak AMY (2007) Industrial gas turbines—performance and operability. Woodhead Publishing Limited, Cambridge

Cohen H, Rogers GFC, Saravanamuttoo HIH (1996) Gas turbine theory, 4th edn. Longman Group Limited, Essex

Asgari H, Chen X, Morini M, Pinelli M, Sainudiin R, Spina PR, Venturini M (2016) NARX models for simulation of the start-up operation of a single-shaft gas turbine. Appl Therm Eng 93:368–376

Rossi I, Sorce A, Traverso A (2017) Gas turbine combined cycle start-up and stress evaluation: a simplified dynamic approach. Appl Energy 190:880–890

Ata AB, Alobaid F, Heinze C, Almoslh A, Sanfeliu A, Epple B (2020) Comparison and validation of three process simulation programs during warm start-up procedure of a combined cycle power plant. Energy Conver Manag 207:112547

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Jose A. R. Parise.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Celis, C., Pinto, G.R.S., de Souza, J.P.I. et al. On dynamic modeling of industrial gas turbines based on low calorific value (LCV) gaseous fuels. J Braz. Soc. Mech. Sci. Eng. 42, 238 (2020). https://doi.org/10.1007/s40430-020-02331-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02331-4