Abstract

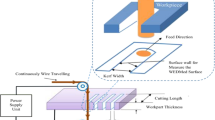

The present study analyzed the effects of cold treated brass wire electrode for the machining of hardened high-strength low-alloy (HSLA) steel on wire electric discharge machine. Cold treatment of brass wire at − 70 °C for 24 h has refined its microstructure which results in an increase in electrical conductivity by 24.5%. The experimental work is designed using fractional factorial design to determine the relationship of input variables including servo voltage (SV), pulse on time (Ton), pulse off time (Toff), wire type (Wt), wire tension (Tw), and flushing pressure (Fp) and response measures including cutting speed (CS), surface roughness (Ra), and kerf width (Kf). In Wt, two kinds of brass wires including cold treated (CT) and non-cold treated (NCT) have been used. Empirical models for cutting speed (CS), surface roughness (Ra), and kerf width (Kf) are developed, and their contribution is analyzed through the analysis of variance (ANOVA) technique. Desirability function offers the best combination of input variables to maximize CS and minimize both Ra and Kf simultaneously. Ton is observed as the most effective input variable for all response measures, followed by Wt and Toff. CT brass wire has been observed as the best alternative in multi-objective optimization.

Similar content being viewed by others

Abbreviations

- WEDM:

-

Wire electric discharge machining

- ECM:

-

Electric chemical machining

- WJM:

-

Water jet machining

- HSLA:

-

High-speed low alloy

- ANOVA:

-

Analysis of variance

- SV:

-

Servo voltage

- T on :

-

Pulse on time

- T off :

-

Pulse off time

- W t :

-

Wire type

- T w :

-

Wire tension

- F p :

-

Flushing pressure

- CT:

-

Cold treated

- NCT:

-

Non-cold treated

- CS:

-

Cutting speed

- Ra:

-

Surface roughness

- Kf:

-

Kerf width

- I :

-

Discharge current

- C :

-

Capacitance

- MRR:

-

Material removal rate

- SS:

-

Sum of square

- df :

-

Degree of freedom

- MS:

-

Mean square

- R 2 :

-

Coefficient of determination

- C.V:

-

Coefficient of variation

References

Show B et al (2010) Effect of vanadium and titanium modification on the microstructure and mechanical properties of a microalloyed HSLA steel. Mater Sci Eng A 527(6):1595–1604

Lu P et al (2017) Microstructure and failure analysis of flash butt welded HSLA 590CL steel joints in wheel rims. JOM 69(2):135–143

Rashid M (1980) High-strength, low-alloy steels. Science 208(4446):862–869

Pandey PC, Shan H (1980) Modern machining processes. Tata McGraw-Hill Education, New York

Manikandan N, Kumanan S, Sathiyanarayanan C (2017) Optimisation of electrochemical drilling process using Taguchi method and regression analysis. Int J Mach Mach Mater 19(2):136–159

Manikandan N, Kumanan S, Sathiyanarayanan C (2017) Multiple performance optimization of electrochemical drilling of Inconel 625 using Taguchi based grey relational analysis. Eng Sci Technol Int J 20(2):662–671

Manikandan N et al (2019) Influence of wire-EDM textured conventional tungsten carbide inserts in machining of aerospace materials (Ti–6Al–4V alloy). Mater Manuf Process 34(1):103–111

Soni H, Sannayellappa N, Rangarasaiah RM (2017) An experimental study of influence of wire electro discharge machining parameters on surface integrity of TiNiCo shape memory alloy. J Mater Res 32(16):3100–3108

Raju R et al (2018) Optimization of process parameters in electrical discharge machining of haste alloy C276 using Taguchi’s method. Mater Today Proc 5(6, Part 2):14432–14439

Das AK et al (2016) Influence of process parameters on the surface integrity of micro-holes of SS304 obtained by micro-EDM. J Braz Soc Mech Sci Eng 38(7):2029–2037

Meshram DB, Puri YM (2017) Review of research work in die sinking EDM for machining curved hole. J Braz Soc Mech Sci Eng 39(7):2593–2605

Ikram A et al (2013) Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J Mech Sci Technol 27(7):2133–2141

Shah A et al (2011) Material removal rate, kerf, and surface roughness of tungsten carbide machined with wire electrical discharge machining. J Mater Eng Perform 20(1):71–76

Singh V, Pradhan S (2014) Optimization of WEDM parameters using Taguchi technique and response surface methodology in machining of AISI D2 steel. Proc Eng 97:1597–1608

Rao PS, Ramji K, Satyanarayana B (2014) Experimental investigation and optimization of wire EDM parameters for surface roughness, MRR and white layer in machining of aluminium alloy. Proc Mater Sci 5:2197–2206

Saha P et al (2008) Soft computing models based prediction of cutting speed and surface roughness in wire electro-discharge machining of tungsten carbide cobalt composite. Int J Adv Manuf Technol 39(1):74–84

Mahapatra SS, Patnaik A (2007) Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method. Int J Adv Manuf Technol 34(9):911–925

Azam M et al (2016) Modeling of cutting speed (CS) for HSLA steel in wire electrical discharge machining (WEDM) using moly wire. J Chin Inst Eng 39(7):802–808

Bobbili R, Madhu V, Gogia A (2015) Modelling and analysis of material removal rate and surface roughness in wire-cut EDM of armour materials. Eng Sci Technol Int J 18(4):664–668

Shakeri S et al (2016) Investigation of material removal rate and surface roughness in wire electrical discharge machining process for cementation alloy steel using artificial neural network. Int J Adv Manuf Technol 82(1–4):549–557

Reitz W, Pendray J (2001) Cryoprocessing of materials: a review of current status. Mater Manuf Process 16(6):829–840

Isaak CJ, Reitz W (2007) The effects of cryogenic treatment on the thermal conductivity of GRCop-84. Mater Manuf Process 23(1):82–91

Jafferson J, Hariharan P (2013) Machining performance of cryogenically treated electrodes in microelectric discharge machining: a comparative experimental study. Mater Manuf Process 28(4):397–402

Gill SS et al (2010) Cryoprocessing of cutting tool materials—a review. Int J Adv Manuf Technol 48(1–4):175–192

Gill SS, Singh J (2010) Effect of deep cryogenic treatment on machinability of titanium alloy (Ti-6246) in electric discharge drilling. Mater Manuf Process 25(6):378–385

Arockia Jaswin M, Mohan Lal D (2010) Optimization of the cryogenic treatment process for En 52 valve steel using the Grey-Taguchi method. Mater Manuf Process 25(8):842–850

Smol’nikov E, Kossovich G (1980) Cold treatment of cutting tools. Met Sci Heat Treat 22(10):704–705

Kapoor J, Singh S, Khamba JS (2012) Effect of cryogenic treated brass wire electrode on material removal rate in wire electrical discharge machining. Proc Inst Mech Eng Part C J Mech Eng Sci 226(11):2750–2758

Goyal A (2017) Investigation of material removal rate and surface roughness during wire electrical discharge machining (WEDM) of Inconel 625 super alloy by cryogenic treated tool electrode. J King Saud Univ Sci 29(4):528–535

Nayak BB, Mahapatra SS (2016) Optimization of WEDM process parameters using deep cryo-treated Inconel 718 as work material. Eng Sci Technol Int J 19(1):161–170

Kapoor J, Khamba JS, Singh S (2012) Effect of shallow cryogenic treated brass wire electrode on workpiece surface roughness in wire-EDM. Int J Mater Eng Innov 3(3–4):190–203

Kapoor J, Khamba JS, Singh S (2011) Effects of cryogenic treated wire electrode on the surface of an EN-31 steel machined by WEDM. Int J Surf Eng Mater Technol 1(1):43–47

Tarng Y, Ma S, Chung L (1995) Determination of optimal cutting parameters in wire electrical discharge machining. Int J Mach Tools Manuf 35(12):1693–1701

Azam M et al (2016) Parametric analysis of recast layer formation in wire-cut EDM of HSLA steel. Int J Adv Manuf Technol 87(1–4):713–722

Sharma N et al (2013) Modeling and multiresponse optimization on WEDM for HSLA by RSM. Int J Adv Manuf Technol 67(9):2269–2281

Tosun N, Cogun C, Tosun G (2004) A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J Mater Process Technol 152(3):316–322

Manton RB (1988) High strength weldable seamless tube of low alloy steel. Google Patents

Azam M et al (2016) Parametric analysis of recast layer formation in wire-cut EDM of HSLA steel. Int J Adv Manuf Technol 87(1):713–722

Ishfaq K et al (2018) Investigation of wire electric discharge machining of stainless-clad steel for optimization of cutting speed. Int J Adv Manuf Technol 96(1):1429–1443

Akhtar MU, Raza MH, Shafiq M (2019) Role of batch size in scheduling optimization of flexible manufacturing system using genetic algorithm. J Ind Eng Int 15(1):135–146

Alidoosti A et al (2013) Electrical discharge machining characteristics of nickel–titanium shape memory alloy based on full factorial design. J Intell Mater Syst Struct 24(13):1546–1556

Jung JH, Kwon WT (2010) Optimization of EDM process for multiple performance characteristics using Taguchi method and Grey relational analysis. J Mech Sci Technol 24(5):1083–1090

Lin C, Lin J, Ko T (2002) Optimisation of the EDM process based on the orthogonal array with fuzzy logic and grey relational analysis method. Int J Adv Manuf Technol 19(4):271–277

Bal KS, Dutta Majumdar J, Roy Choudhury A (2018) Minimization of bead geometry by optimization of regression equations for laser-beam bead-on-plate welded Hastelloy C-276 sheet. J Braz Soc Mech Sci Eng 40(9):451

Montgomery DC (2017) Design and analysis of experiments. Wiley, New York

Abellan-Nebot JV, Subirón FR (2010) A review of machining monitoring systems based on artificial intelligence process models. Int J Adv Manuf Technol 47(1–4):237–257

Yu J et al (2017) Multi-objective optimizations of multidirectional forming mold based on fractional factorial design. Int J Adv Manuf Technol 88(1–4):1151–1160

Patil NG, Brahmankar PK (2010) Some studies into wire electro-discharge machining of alumina particulate-reinforced aluminum matrix composites. Int J Adv Manuf Technol 48(5):537–555

Singh V, Bhandari R, Yadav VK (2017) An experimental investigation on machining parameters of AISI D2 steel using WEDM. Int J Adv Manuf Technol 93(1):203–214

Aggarwal V, Khangura SS, Garg RK (2015) Parametric modeling and optimization for wire electrical discharge machining of Inconel 718 using response surface methodology. Int J Adv Manuf Technol 79(1):31–47

Manikandan N et al (2019) Investigations on wire spark erosion machining of aluminum-based metal matrix composites. Springer, Singapore

Tahir W et al (2019) Surface morphology evaluation of hardened HSLA steel using cryogenic-treated brass wire in WEDM process. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04301-0

Raza MH et al (2019) Modeling of the mechanical properties of directionally solidified Al–4.3% Cu alloy using response surface methodology. Int J Adv Manuf Technol 103(9–12):3913–3925

Raza MH et al (2018) Investigating the effects of different electrodes on Al6061-SiC-7.5 wt% during electric discharge machining. Int J Adv Manuf Technol 99(9–12):3017–3034

Ali MA et al (2018) Evaluating the effects of as-casted and aged overcasting of Al–Al joints. Int J Adv Manuf Technol 96(1):1377–1392

Chalisgaonkar R, Kumar J (2016) Investigation of the machining parameters and integrity of the work and wire surfaces after finish cut WEDM of commercially pure titanium. J Braz Soc Mech Sci Eng 38(3):883–911

Kumar H, Manna A, Kumar R (2018) Modeling and desirability approach-based multi-response optimization of WEDM parameters in machining of aluminum metal matrix composite. J Braz Soc Mech Sci Eng 40(9):458

Sarfraz S et al (2017) Investigating the effects of as-casted and in situ heat-treated squeeze casting of Al–3.5% Cu alloy. Int J Adv Manuf Technol 89(9–12):3547–3561

Patil NG, Brahmankar P (2010) Some studies into wire electro-discharge machining of alumina particulate-reinforced aluminum matrix composites. Int J Adv Manuf Technol 48(5–8):537–555

Sharma P, Chakradhar D, Narendranath S (2015) Evaluation of WEDM performance characteristics of Inconel 706 for turbine disk application. Mater Des 88:558–566

Rao TB, Krishna AG (2014) Selection of optimal process parameters in WEDM while machining Al7075/SiCp metal matrix composites. Int J Adv Manuf Technol 73(1):299–314

Khan MAR, Rahman M, Kadirgama K (2015) An experimental investigation on surface finish in die-sinking EDM of Ti–5Al–2.5 Sn. Int J Adv Manuf Technol 77(9–12):1727–1740

Abbasi JA et al (2017) Effects of wire-Cut EDM process parameters on surface roughness of HSLA steel. Int J Adv Manuf Technol 91(5–8):1867–1878

Rao TB, Krishna AG (2014) Selection of optimal process parameters in WEDM while machining Al7075/SiCp metal matrix composites. Int J Adv Manuf Technol 73(1–4):299–314

Yang RT et al (2012) Optimization of wire electrical discharge machining process parameters for cutting tungsten. Int J Adv Manuf Technol 60(1–4):135–147

Okada A et al (2010) Evaluations of spark distribution and wire vibration in wire EDM by high-speed observation. CIRP Ann 59(1):231–234

Prasad D, Krishna AG (2015) Empirical modeling and optimization of kerf and wire wear ratio in wire electrical discharge machining. Int J Adv Manuf Technol 77(1–4):427–441

Rajyalakshmi G, Ramaiah PV (2013) Multiple process parameter optimization of wire electrical discharge machining on Inconel 825 using Taguchi grey relational analysis. Int J Adv Manuf Technol 69(5–8):1249–1262

Derringer G, Suich R (1980) Simultaneous optimization of several response variables. J Qual Technol 12(4):214–219

Devarajaiah D, Muthumari C (2018) Evaluation of power consumption and MRR in WEDM of Ti–6Al–4 V alloy and its simultaneous optimization for sustainable production. J Braz Soc Mech Sci Eng 40(8):400

El-Taweel T (2009) Multi-response optimization of EDM with Al–Cu–Si–TiC P/M composite electrode. Int J Adv Manuf Technol 44(1–2):100–113

Natarajan U, Periyanan P, Yang S (2011) Multiple-response optimization for micro-endmilling process using response surface methodology. Int J Adv Manuf Technol 56(1–4):177–185

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Marcelo Areias Trindade.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tahir, W., Jahanzaib, M. Multi-objective optimization of WEDM using cold treated brass wire for HSLA hardened steel. J Braz. Soc. Mech. Sci. Eng. 41, 525 (2019). https://doi.org/10.1007/s40430-019-2028-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2028-9