Abstract

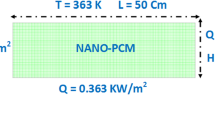

Latent heat thermal energy storage (LHTES) plays a main role in many industrial applications, especially in high-powered electronics cooling systems and providing the thermal energy demand when the energy supply is unavailable. In this study, the LHTES cycle process, including successive melting and solidification, investigates in a two-dimensional annular space of a square cavity filled with nanomaterial of paraffin–alumina as a nanoPCM. In the melting process, all sidewalls of the cavity are insulated. Meanwhile, a constant heat rate generates homogeneously within the central heat source. At the end of melting, the heat generation gets off, while a time-reducing temperature lower than the paraffin melting point imposes on the sidewalls, and then, solidification triggers. The numerical simulation was accomplished using control volume method and the governing equations solved using the SIMPLE algorithm. The enthalpy-porosity method was employed to model the phase-change front. The value of thermal conductivity and the viscosity of the nanofluid have been experimentally measured before the numerical modeling. In this study, the effect of volume fraction of nanoparticles (0–0.03) has been investigated on the successive melting and solidification rate for a constant Rayleigh number of 5.74 × 105. The results show that adding nanoparticles to the PCM equal to the volume fractions of 0.01 and 0.02 improves melting rate, but the nanofluid with the volume fraction of 0.03 represents a poor heat transfer rate during melting even weaker than those for nanofluid with the volume fraction of 0.01. It also observed that the nanomaterial with the volume fraction of φ = 0.03 represents the highest solidification rate. However, taking the overall performance of successive melting and solidification system into account, the nanofluid with the volume fraction of 0.02 remarked the most effective heat transfer rate in comparison with the other examined cases.

Similar content being viewed by others

Abbreviations

- b :

-

Enthalpy-porosity coefficient (kg m−3 s−1)

- B :

-

Dimensionless enthalpy-porosity coefficient

- B z :

-

Boltzmann constant

- c :

-

Specific heat (J kg−1 K−1)

- f :

-

Liquid fraction

- g :

-

Gravity (m s−2)

- h :

-

Enthalpy (J kg−1 K−1)

- L, l :

-

Cavity and heat source dimension (m)

- k :

-

Thermal conductivity (W m−1 K−1)

- Nu :

-

Nusselt number, \(- k_{\text{nf}} /k_{\text{f}} (T_{\text{s}} - T_{\text{m}} )\partial T/\partial n\)

- p :

-

Pressure (N m−2)

- P :

-

Dimensionless pressure

- Pr :

-

Prandtl number, \(Pr = \nu_{\text{f}} /\alpha_{\text{f}}\)

- q′″:

-

Heat generation rate (W m−3)

- Ra :

-

Rayleigh number, \(g\beta_{\text{f}} q^{{{\prime \prime \prime }}} l^{5} /\nu_{\text{f}} \alpha_{\text{f}} k_{\text{s}}\)

- Ste :

-

Stefan number, \(c_{\text{f}} q^{{{\prime \prime \prime }}} l^{2} /h_{\text{nf}} k_{\text{s}}\)

- T :

-

Temperature (K)

- T m, T s :

-

Melting and solidification points (K)

- T h, T c :

-

Hot and cold temperatures (K)

- t :

-

Time (s)

- u, v :

-

Velocity in the x, y direction (m s−1)

- U, V :

-

Dimensionless velocity

- x, y :

-

Cartesian coordinate (m)

- X, Y :

-

Dimensionless Cartesian coordinate

- CLF:

-

Cavity liquid fraction

- PCM:

-

Phase-change material

- NePCM:

-

Nano-enhanced PCM

- α :

-

Thermal diffusivity (m2 s−1)

- β :

-

Expansion coefficient (K−1)

- μ :

-

Dynamic viscosity (N s m−2)

- ν :

-

Kinematic viscosity (m2 s−1)

- θ :

-

Dimensionless temperature

- ρ :

-

Density (kg m−3)

- ϕ :

-

Volume fraction

- σ :

-

Electrical conduction (S m−1)

- τ:

-

Dimensionless time

- f, s:

-

Fluid and solid

- m:

-

Melting point

- nf:

-

Fluid PCM with nanoparticles

- ns:

-

Solid PCM with nanoparticles

- np:

-

Nanoparticles

References

Alva G, Liu L, Huang X, Fang G (2017) Thermal energy storage materials and systems for solar energy applications. Renew Sustain Energy Rev 68:693–706

Py X, Azoumah Y, Olives R (2013) Concentrated solar power: current technologies, major innovative issues and applicability to West African countries. Renew Sustain Energy Rev 18:306–315

Agyenim F, Hewitt N, Eames P, Smyth M (2010) A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew Sustain Energy Rev 14:615–628

De Souza S, Vielmo HA (2005) Numerical analysis of water melting and solidification in the interior of tubes. J Braz Soc Mech Sci Eng 27:119–131

Tian Y, Zhao C-Y (2013) A review of solar collectors and thermal energy storage in solar thermal applications. Appl Energy 104:538–553

Xu B, Li P, Chan C (2015) Application of phase change materials for thermal energy storage in concentrated solar thermal power plants: a review to recent developments. Appl Energy 160:286–307

Jourabian M, Farhadi M, Darzi AR (2012) Simulation of natural convection melting in an inclined cavity using lattice Boltzmann method. Sci Iran 19:1066–1073

Babapoor A, Karimi G (2015) Thermal properties measurement and heat storage analysis of paraffinnanoparticles composites phase change material: comparison and optimization. Appl Therm Eng 90:945–951

Khodadadi J, Hosseinizadeh S (2007) Nanoparticle-enhanced phase change materials (NEPCM) with great potential for improved thermal energy storage. Int Commun Heat Mass Transf 34:534–543

Hu N, Zhu Z-Q, Li Z-R, Tu J, Fan L-W (2018) Close-contact melting heat transfer on a heated horizontal plate: revisited in the presence of nano-enhanced phase change materials (NePCM). Int J Heat Mass Transf 124:794–799

Sheikholeslami M (2018) Numerical simulation for solidification in a LHTESS by means of Nano-enhanced PCM. J Taiwan Inst Chem Eng 86:25–41

Iachachene F, Haddad Z, Oztop HF, Abu-Nada E (2019) Melting of phase change materials in a trapezoidal cavity: Orientation and nanoparticles effects. J Mol Liq 318:441–450

Sheikholeslami M, Mahian O (2019) Enhancement of PCM solidification using inorganic nanoparticles and an external magnetic field with application in energy storage systems. J Clean Prod 215:963–977

Dadvand A, Boukani NH, Dawoodian M (2018) Numerical simulation of the melting of a NePCM due to a heated thin plate with different positions in a square enclosure. Therm Sci Eng Prog 7:248–266

Feng Y, Li H, Li L, Bu L, Wang T (2015) Numerical investigation on the melting of nanoparticle-enhanced phase change materials (NEPCM) in a bottom-heated rectangular cavity using lattice Boltzmann method. Int J Heat Mass Transf 81:415–425

Arıcı M, Tütüncü E, Kan M, Karabay H (2017) Melting of nanoparticle-enhanced paraffin wax in a rectangular enclosure with partially active walls. Int J Heat Mass Transf 104:7–17

Sebti SS, Mastiani M, Mirzaei H, Dadvand A, Kashani S, Hosseini SA (2013) Numerical study of the melting of nano-enhanced phase change material in a square cavity. J Zhejiang Univ Sci A 14:307–316

Farsani RY, Raisi A, Nadooshan AA, Vanapalli S (2017) Does nanoparticles dispersed in a phase change material improve melting characteristics? Int Commun Heat Mass Transf 89:219–229

Darzi AR, Farhadi M, Jourabian M (2013) Lattice Boltzmann simulation of heat transfer enhancement during melting by using nanoparticles. Iran J Sci Technol Trans Mech Eng 37:23

Boukani NH, Dadvand A, Chamkha AJ (2018) Melting of a Nano-enhanced Phase Change Material (NePCM) in partially-filled horizontal elliptical capsules with different aspect ratios. Int J Mech Sci 149:164–177

Kashani S, Ranjbar A, Madani M, Mastiani M, Jalaly H (2013) Numerical study of solidification of a nano-enhanced phase change material (NEPCM) in a thermal storage system. J Appl Mech Tech Phys 54:702–712

Khodadadi J, Fan L (2009) Expedited freezing of nanoparticle-enhanced phase change materials (NEPCM) exhibited through a simple 1-D stefan problem formulation. In: ASME Summer Heat Transfer Conference, San Francisco, CA, July, 2009, pp 19–23

Maxwell JC (1881) A treatise on electricity and magnetism. Clarendon Press, Oxford

Kumar S, Bhoopal RS, Sharma PK, Beniwal RS, Singh R (2011) Non-linear effect of volume fraction of inclusions on the effective thermal conductivity of composite materials: a modified Maxwell model. Open J Compos Mater 1:10

Vand V (1948) Viscosity of solutions and suspensions. I. Theory. J Phys Chem 52:277–299

Mózes G (1983) Paraffin products. Elsevier, Amsterdam

Arasu AV, Mujumdar AS (2012) Numerical study on melting of paraffin wax with Al2O3 in a square enclosure. Int Commun Heat Mass Transf 39:8–16

Hammerschmidt U, Sabuga W (2000) Transient hot wire (THW) method: uncertainty assessment. Int J Thermophys 21:1255–1278

Shahsavar A, Bahiraei M (2017) Experimental investigation and modeling of thermal conductivity and viscosity for non-Newtonian hybrid nanofluid containing coated CNT/Fe3O4 nanoparticles. Powder Technol 318:441–450

Brent A, Voller V, Reid K (1988) Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer Heat Transf Part A Appl 13:297–318

Hunter L, Kuttler J (1989) The enthalpy method for heat conduction problems with moving boundaries. J Heat Transf Trans ASME 111:239–242

Zerroukat M, Chatwin CR (1994) Computational moving boundary problems. Research Studies Press, Baldock

Patankar S (1980) Numerical heat transfer and fluid flow. CRC Press, Boca Raton

Voller V, Swaminathan C, Thomas BG (1990) Fixed grid techniques for phase change problems: a review. Int J Numer Methods Eng 30:875–898

Date A (1991) A strong enthalpy formulation for the Stefan problem. Int J Heat Mass Transf 34:2231–2235

Gau C, Viskanta R (1986) Melting and solidification of a pure metal on a vertical wall. J Heat Transf 108:174–181

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Technical Editor: Francis HR Franca, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yadollahi Farsani, R., Raisi, A. & Mahmoudi, A. Successive melting and solidification of paraffin–alumina nanomaterial in a cavity as a latent heat thermal energy storage. J Braz. Soc. Mech. Sci. Eng. 41, 368 (2019). https://doi.org/10.1007/s40430-019-1859-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1859-8