Abstract

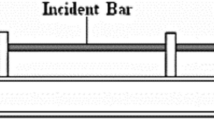

Quasi-static compression and tensile tests were conducted on Armox 500T steel in the range of strain rates from 10−4 to 10−1 s−1 to evaluate strength differential (S-D) effect. Dynamic flow behavior under compressive loading conditions at strain rates of 102–103 s−1 was measured by conducting a series of tests on split-Hopkinson pressure bar setup. Further, J–C material model parameters have been established considering static and dynamic compression test data at strain rates of 10−3–103 s−1. Subsequently, FE modeling was carried out to validate J–C material model parameters and compared with the set of previous studies. The comparative study revealed the presence of S-D effect on the plastic flow behavior of the test material. Strain–time pulse as well as stress–strain response of Armox 500T steel obtained from simulation had a good agreement with the experimental results. The data generated from the present work will be helpful in the design and development of armor vehicles and other military structures against different threat scenarios.

Similar content being viewed by others

References

Zejian Xu, Huang Fenglei (2012) Plastic behavior and constitutive modeling of armor steel over wide temperature and strain rate ranges. Acta Mech Solida Sin 25:598–608

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th international symposium on ballistics, vol 21, pp 541–547

Banerjee A, Dhar S, Acharyya S, Datta D, Nayak N (2015) Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of armour steel. Mater Sci Eng A 640:200–209

Kılıç N, Ekici B (2013) Ballistic resistance of high hardness armor steels against 7.62 mm armor piercing ammunition. Mater Des 44:35–48

Nilsson M (2003) Constitutive model for Armox 500T and Armox 600T at low and medium strain rates, weapons and protection SE-147/25

Bridgman PW (1952) Studies in large plastic flow and fracture, vol 177. McGraw-Hill, New York

Singh AP, Padmanabhan KA, Pandey GN, Murty GMD, Jha S (2000) Strength differential effect in four commercial steels. J Mater Sci 35:1379–1388

Merz MD (1973) Strength differential effect in α-Pu. Metall Mater Trans B 4:1186–1188

Mannan SL, Rodriguez P (1971) The strength-differential phenomenon in zircaloy-2. Scr Metall 5:71–74

Lowden MAW, Hutchinson WB (1975) Texture strengthening and strength differential in titanium–6Al–4V. Metall Trans A 6:441

Olsen RJ, Ansell GS (1969) Strength differential in two-phase alloys. ASM Trans Quart 62:711–720

Drucker DC (1973) Plasticity theory strength-differential (SD) phenomenon, and volume expansion in metals and plastics. Metall Mater Trans B 4:667–673

Arsenault RJ, Taya Minoru (1987) Thermal residual stress in metal matrix composite. Acta Metall 35:651–659

Yong Liu, Xie Zeliang, Van Humbeeck Jan, Delaeyet Luc (1998) Asymmetry of stress–strain curves under tension and compression for Ni–Ti shape memory alloys. Acta Mater 46:4325–4338

Chait R (1972) Factors influencing the strength differential of high strength steels. Metall Trans 3:369–375

Holmen JK, Frodal BH, Hopperstad OS, Børvik T (2017) Strength differential effect in age hardened aluminum alloys. Int J Plast 99:144–161

Seidt JD, Gilat A (2013) Plastic deformation of 2024-T351 aluminum plate over a wide range of loading conditions. Int J Solids Struct 50:1781–1790

Gao X, Zhang T, Zhou J, Graham SM, Hayden M, Roe C (2011) On stress-state dependent plasticity modeling: significance of the hydrostatic stress, the third invariant of stress deviator and the non-associated flow rule. Int J Plast 27:217–231

Lou Y, Huh H, Yoon JW (2013) Consideration of strength differential effect in sheet metals with symmetric yield functions. Int J Mech Sci 66:214–223

Luo M, Rousselier G (2014) Modeling of large strain multi-axial deformation of anisotropic metal sheets with strength-differential effect using a reduced texture methodology. Int J Plast 53:66–89

Yoon JW, Lou Y, Yoon J, Glazoff MV (2014) Asymmetric yield function based on the stress invariants for pressure sensitive metals. Int J Plast 56:184–202

Kleiser GJ, Revil-Baudard B, Cazacu O, Pasiliao CL (2015) Plastic deformation of polycrystalline molybdenum: experimental data and macroscopic model accounting for its anisotropy and tension–compression asymmetry. Int J Solids Struct 75:287–298

Nixon ME, Cazacu O, Lebensohn RA (2010) Anisotropic response of high-purity α-titanium: experimental characterization and constitutive modeling. Int J Plast 26:516–532

Tuninetti V, Gilles G, Milis O, Pardoen T, Habraken AM (2015) Anisotropy and tension–compression asymmetry modeling of the room temperature plastic response of Ti–6Al–4V. Int J Plast 67:53–68

Habib SA, Khan AS, Gnäupel-Herold T, Lloyd JT, Schoenfeld SE (2017) Anisotropy, tension–compression asymmetry and texture evolution of a rare-earth-containing magnesium alloy sheet, ZEK100, at different strain rates and temperatures: experiments and modeling. Int J Plast 95:163–190

Shahzad M, Wagner L (2009) The role of Zr-rich cores in strength differential effect in an extruded Mg–Zn–Zr alloy. J Alloy Compd 486:103–108

Rauch GC, Leslie WC (1972) The extent and nature of the strength-differential effect in steels. Metall Trans 3:377–389

Leslie WC, Sober RJ (1968) The strength of ferrite and of martensite as functions of composition, temperature, and strain rate. Trans ASM 60:459–484

Ellermann A, Scholtes B (2015) The strength differential effect in different heat treatment conditions of the steels 42CrMoS4 and 100Cr6. Mater Sci Eng A 620:262–272

Maeda T, Noma N, Kuwabara T, Barlat F, Korkolis YP (2018) Measurement of the strength differential effect of DP980 steel sheet and experimental validation using pure bending test. J Mater Process Technol 256:247–253

Pampillo CA, Davis LA, Li JCM (1972) Reply to “some comments on the effective modulus interpretation of the strength-differential effect in ferrous alloys. Scr Metall 6:765–768

Leslie WC (1972) The effective modulus interpretation of the strength-differential effect in ferrous alloys. Scr Metall 6:1145–1146

Pampillo CA, Davis LA, Li JCM (1973) Reply to “some comments on the effective modulus interpretation of the strength differential effect in ferrous alloys. Scr Metall 7:255–257

Pampillo CA, Davis LA, Li JCM (1974) Reply to further comments on the effective modulus interpretation of the strength differential effect in ferrous alloys. Scr Metall 8:685–688

Hirth JP, Cohen Morris (1970) On the strength-differential phenomenon in hardened steel. Metall Trans 1:3–8

Spitzig WA, Richmond O (1984) The effect of pressure on the flow stress of metals. Acta Metall 32:457–463

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. In: Proceedings of the physical society, section B, vol 62, p 676

Mohr D, Gary G, Lundberg B (2010) Evaluation of stress–strain curve estimates in dynamic experiments. Int J Impact Eng 37:161–169

Rodriguez J, Cortés R, Martínez MA, Sánchez-Gálvez V, Navarro C (1995) Numerical study of the specimen size effect in the split Hopkinson pressure bar tests. J Mater Sci 30:4720–4725

Bhadeshia HKDH and Institute of Materials (1992) Bainite in steels. Institute of Materials, London

David Kalish, Cohen Morris (1969) Anisotropy of properties in martensite as developed by thermomechanical treatments. ASM Trans Quart 62:353–361

Patel JR, Cohen Morris (1953) Criterion for the action of applied stress in the martensitic transformation. Acta Metall 1:531–538

Rauch GC, Leslie WC (1972) The extent and nature of the strength-differential effect in steels. Metall Trans 3:373–385

Radcliffe SV (1969) Reported at the 1969 spring meeting of TMS-AIME by GC Rauch and WC Leslie. J Met 21:27a

Snowden KU (1971) Comments on: the strength differential phenomenon in zircaloy-2. Scr Metall 5:467–468

Natal YD, Monteiro SN (1977) Strength-differential effect in 4340 steel. Met ABM 33(234):269–273

Wang ZG, Meyer LW (2010) On the plastic wave propagation along the specimen length in SHPB test. Exp Mech 50:1061–1074

Miao YG et al (2016) Determination of dynamic elastic modulus of polymeric materials using vertical split Hopkinson pressure bar. Int J Mech Sci 108:188–196

Jung JA (1981) Note on the influence of hydrostatic pressure on dislocations. Philos Mag A 43:1057–1061

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the FCC case. Prog Mater Sci 48:171–273

Lee WS, Chou JK (2005) The effect of strain rate on the impact behaviour of Fe-2 mass% Ni sintered alloy. Mater Trans 46:805–811

Acknowledgements

The authors are grateful to Vice Chancellor, DIAT (DU), Pune, for permitting to publish this paper in the journal. The authors are also thankful to Director, DMRL, Hyderabad, for extending the facilities for conducting a number of experiments. Acknowledgments are also due to the scientists and technical staff from Armor division, DMRL, Hyderabad.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça.

Rights and permissions

About this article

Cite this article

Saxena, A., Kumaraswamy, A. & Vemuri, M. Investigation of S-D effect on plastic flow behavior of Armox 500T steel. J Braz. Soc. Mech. Sci. Eng. 40, 463 (2018). https://doi.org/10.1007/s40430-018-1381-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1381-4