Abstract

A three-dimensional numerical model has been prepared for the simulation of temperature profile and temperature gradient in similar and dissimilar laser welding. A three-dimensional Gaussian heat distribution equation for moving heat source with conical shape has been incorporated in the present study. A finite element code using software ANSYS APDL has been developed which takes into account the thermal and mechanical aspect of the materials. Properties of the materials AISI 304 austenitic stainless steel and St37 low carbon steel are taken as temperature dependent in the present simulation, which has great influence on the temperature profile. The laser welding temperature distribution was measured using K-type thermocouples with the help of data logger. A good agreement was found between the numerical and experimental results.

Similar content being viewed by others

References

Rosenthal D (1946) The theory of moving sources of heat and its application of metal treatments. Tran ASME 68:849–866

Frewin MR, Scott DA (1999) Finite element model of pulsed laser welding. Weld J New York 78:15-s

Shanmugam NS, Buvanashekaran G, Sankaranarayanasamy K, Manonmani K (2009) Some studies on temperature profiles in AISI 304 stainless steel sheet during laser beam welding using FE simulation. Int J of Adv Manuf Technol 43:78–94

Tsirkas SA, Papanikos P, Kermanidis T (2003) Numerical simulation of the laser welding process in butt-joint specimens. J Mater Process Technol 134:59–69

Casalino G, Mortello M, Peyre P (2016) FEM analysis of fiber laser welding of titanium and aluminum. Proc CIRP 41:992–997

GuoMing H, Jian Z, JianQang L (2007) Dynamic simulation of the temperature field of stainless steel laser welding. Mater Des 28:240–245

Chukkan JR, Vasudevan M, Muthukumaran S, Kumar RR, Chandrasekhar N (2015) Simulation of laser butt welding of AISI 316L stainless steel sheet using various heat sources and experimental validation. J Mater Process Technol 219:48–59

Spina R, Tricarico L, Basile G, Sibillano T (2007) Thermo-mechanical modeling of laser welding of AA5083 sheets. J Mater Process Technol 191:215–219

Wang R, Lei Y, Shi Y (2011) Numerical simulation of transient temperature field during laser keyhole welding of 304 stainless steel sheet. Opt Laser Technol 43:870–873

Kim K, Lee J, Cho H (2010) Analysis of pulsed Nd:YAG laser welding of AISI 304 steel. J Mech Sci Technol 24:2253–2259

Akman E, Demir A, Canel T, Sınmazçelik T (2009) Laser welding of Ti6Al4V titanium alloys. J Mater Process Technol 209:3705–3713

Kumar KS (2015) Numerical modeling and simulation of a butt joint welding of AISI 316L stainless steels using a pulsed laser beam. Mater Today Proc 2:2256–2266

Attarha MJ, Sattari-Far I (2011) Study on welding temperature distribution in thin welded plates through experimental measurements and finite element simulation. J Mater Process Technol 211:688–694

Dowden J (ed) (2009) The theory of laser materials processing. Heat and mass transfer in modern technology. Springer, Netherlands

Iordachescu M, Ruiz Hervías J, Iordachescu D, Valiente Cancho A, Caballero Molano L (2010) Thermal influence of welding process on strength overmatching of thin dissimilar sheets joints. In: Iberian conference on fracture and structural integrity

Ji Z, Wu S (1998) FEM simulation of the temperature field during the laser forming of sheet metal. J Mater Process Technol 74:89–95

Carmignani C, Mares R, Toselli G (1999) Transient finite element analysis of deep penetration laser welding process in a singlepass butt-welded thick steel plate. Comp Method Appl Mech Eng 179:197–214

Xie J, Kar A (1999) Laser welding of thin sheet steel with surface oxidation. Weld J-New York 78:343-s

Acknowledgements

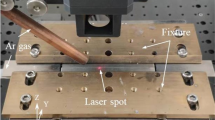

The laser welding was done at Central Mechanical Engineering Research Institute (CMERI) Durgapur, funded by National Institute of Technology Patna, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Kumar, P., Sinha, A.N. Studies of temperature distribution for laser welding of dissimilar thin sheets through finite element method. J Braz. Soc. Mech. Sci. Eng. 40, 455 (2018). https://doi.org/10.1007/s40430-018-1380-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1380-5