Abstract

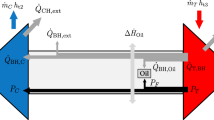

Transient is considered an important operation mode of an engine since most of its working cycles happen in this mode. In this paper, GT-Power software is used to model the engine and the turbocharger; moreover, the experimental results from the IPCO Company are used for validation and calibration. The simulation is calibrated for the engine’s steady state in the part- and full-load conditions. Then, since the transient simulation cannot be performed based on the steady-state settings, the engine transient simulation is calibrated. Upon the performed simulation, the calibration differences of the transient and the steady state are investigated. These differences are analyzed during four processes of combustion, injection, heat transfer in the exhaust manifold and the turbocharger performance; then the various parameters’ effect on the engine transient are studied. The considered transient is the one during which the engine load increases with the throttle opening at a constant engine speed. It is concluded that the produced maps of the combustion and injection parameters, which are achieved from the quasi-steady conditions, can properly predict these parameters’ behavior. However, the turbocharger performance and the heat transfer inside the exhaust manifold must be calibrated, transiently. With this procedure for model calibration, the error between the model and the experimental results were decreased significantly. For example, in the speed of 1900 rpm, the error between the model and the experimental data for transient simulation is reduced from 1.57 to 0.18%. The studied engine is 1.65 L EF7-TC which is a spark ignition engine equipped with a turbocharger.

Similar content being viewed by others

Abbreviations

- aTDC:

-

After top dead center

- BMEP:

-

Brake mean effective pressure (bar)

- CAD:

-

Crank angle degree

- CA50 :

-

50% Burned fuel point (°)

- HTM:

-

Heat transfer multiplier

- IMEP:

-

Indicated mean effective pressure (bar)

- IPCO:

-

Iran Khodro Powertrain Company

- MVEM:

-

Mean value engine model

- PSO:

-

Particle swarm optimization

- QS:

-

Quasi-steady

- SI:

-

Spark ignition

- SS:

-

Steady state

- TEM:

-

Turbine efficiency multiplier

- TC:

-

Turbocharger

- VGT:

-

Variable geometery turbin

- VVT:

-

Variable valve timing

- VNT:

-

Variable nozzle turbine

- WG:

-

Wastegate

- WGD:

-

Wastegate effective diameter (mm)

- WOT:

-

Wide open throttle

- λ:

-

1/Equivalence ratio

References

Muller M, Hendricks E, Sorenson SC (1998) Mean value modelling of turbocharged spark ignition engines. SAE Technical Paper, pp 125–145

Hendricks E, Sorenson S (1990) Mean value SI engine model for control studies. In: American control conference, pp 1882–1887

Andersson P, Eriksson L (2004) Cylinder air charge estimator in turbocharged SI engine. SAE Technical Paper 2004-01-1366

Eriksson L, Frie S, Onder S, Guzzella L (2002) Control and optimization of turbocharged spark ignited engines. In: 15th Triennial world congress, Barcelona

Mueller M (1997) Mean value modeling of turbocharged spark ignition engines. Master’s thesis, DTU

Moraal P, Kolmanovsky L (1999) Turbocharger modeling for automotive control applications. SAE Technical Paper. https://doi.org/10.4271/1999-01-0908

Khiar D, Lauber J, Guerra TM, Floquet T, Chamaillard Y, Colin G (2006) Nonlinear modeling and control approach for a turbocharged SI engine. In: Annual conference on industrial electronics IECON, pp 325–330

Jensen JP, Kristensen AF, Sorenson SC, Houbak N, Hendricks E (1991) Mean value modeling of a small turbocharged diesel engine. SAE Technical Paper. https://doi.org/10.4271/910070

Pettersson F (2000) Simulation of a turbo charged spark ignited engine LiTH-ISY-EX-3010. Master’s thesis, Vehicular Systems Dept. of Electrical Engineering

Rong K (2014) Modeling of turbocharged spark ignited engine and model predictive control of hybrid turbocharger. A thesis presented to the Graduate School of the University of Florida in partial fulfillment of the requirements for the degree of Master of Science

Westin F (2007) Simulation of turbocharged SI engines with focus on the turbine. Doctoral thesis KTH School of Industrial Engineering and Management, Royal Institute of Technology, SE-100 44 Stockholm

Bodin E (2008) Calibration of a transient GT-power model of a SI PFI turbo Engine. Master of Science Thesis MMK 2008:1 MFM117 KTH Industrial Engineering and Management Machine Design SE-100 44 Stockholm

Ericsson G, Angstrom H, Westin F (2010) Optimizing the transient of an SI engine equipped with variable cam timing and variable turbine. SAE Int J Engines 3(1):903–915. https://doi.org/10.4271/2010-01-1233

Ushida H (2006) Transient performance prediction for turbocharging systems incorporating variable-geometry turbochargers. R&D Rev Toyota CRDL 41(3):22–28 (Special issue: turbocharging technologies)

Flardh O, Ericsson G, Klingborg E, Martensson J (2014) Optimal air path control during load transients on a spark ignited engine with variable geometry turbine and variable valve timing. IEEE Trans Control Syst Technol 22(1):83–93

Bozza F, Gimelli A, Strazzullo L, Torella E, et al. (2007) Steady-state and transient operation simulation of a “downsized” turbocharged SI engine. SAE Technical Paper 2007-01-0381, https://doi.org/10.4271/2007-01-0381

Lefebvre A, Guilain S (2005) Modelling and measurement of the transient response of a turbocharged SI engine. In SAE World Congress, Detroit, SAE Technical Paper 2005-01-0691

Kakaee A, Keshavarz M (2017) Simultaneous dynamic optimization of valves timing and waste gate to improve the load step transient response of a turbocharged spark ignition engine. J Braz Soc Mech Sci Eng 39(7):2383–2394. https://doi.org/10.1007/s40430-017-0786-9

Lawler EL, Bell MD (1966) A method for solving discrete optimization problems. J Oper Res Soc Am 14(6):1098–1112

GT-Power v7.3 user’s manual

Kennedy J, Eberhart RC (1995) Particle swarm optimization. In: Proceedings of the 1995 IEEE international conference on neural networks. IEEE Service Center, Piscataway

Liu JL, Lin JH (2007) Evolutionary computation of unconstrained and constrained problems using a novel momentum-type particle swarm optimization. Eng Optim 39:287–305

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Fernando Marcelo Pereira.

Rights and permissions

About this article

Cite this article

Keshavarz, M., Kakaee, AH. & Fajri, H. Analysis and dynamic calibration of the transient of an SI-engine equipped with turbocharger. J Braz. Soc. Mech. Sci. Eng. 40, 358 (2018). https://doi.org/10.1007/s40430-018-1278-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1278-2