Abstract

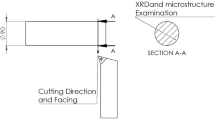

Austempered ductile iron (ADI) is a heat-treated ductile cast iron with ausferrite microstructure. ADI has high strength and hardness with good ductility and toughness. However, because of the high strength and hardness of ADI, there is a concern regarding its machinability. In the present study, machinability of ADI is assessed using tool life and the surface roughness. Machining tests are conducted using Taguchi experimental design. The effects of machining parameters, heat treatment parameters, on manganese alloyed ADI in the dry turning operation are studied and it was found that austempering temperature and cutting speed have the major contributions on tool life, whereas feed rate has the major contribution on surface roughness of the material within the range of values under study. Metallographic study has revealed coarser structure at higher austempering temperature of 420° which resulted in better tool life. 0.64 wt% of manganese in the ADI has resulted in lower surface roughness value.

Similar content being viewed by others

References

Keough JR, Hayrynen KL (2003) World ADI conference on austempered ductile iron. The State of the Industry, Louisville

Parez MJ, Cisneros MM, Lopez HF (2006) Wear resistance of Cu–Ni–Mo austempered ductile iron. Wear 260:879–885

Lerner YS, Kingsbury GR (1997) Wear resistance properties of austempered ductile iron. J Mater Eng Perform 7:48–52

Olawale JO, Oluwasegun KM (2016) Austempered ductile iron (ADI): a review. Mater Perform Charact 5:289–311

Narasimha Murthy K, Sampathkumaran P, Seetharamu S (2009) Abrasion and erosion behaviour of manganese alloyed permanent moulded austempered ductile iron. Wear 267:1393–1398

Barbosa PA, Costa ÉS, Guesser WL et al (2015) Comparative study of the machinability of austempered and pearlitic ductile irons in drilling process. J Braz Soc Mech Sci Eng 37:115–122

Cemal Cakir M, Isik Yahya (2008) Investigating the machinability of austempered ductile irons having different austempering temperatures and times. Mater Des 29(5):937–939

Ulvi Seker and Hasan Hasirci (2006) Evaluation of machinability of austempered ductile irons in terms of cutting forces and surface quality. J Mater Process Technol 173:260–268

Klocke F, Arft M, Lung D (2010) Material-related aspects of the machinability of austempered ductile iron. Prod Eng Res Devel 4:433–441

de Carvalho MV, Montenegro DM, de Oliveira Gomes J (2013) An analysis of the machinability of ASTM grades 2 and 3 austempered ductile iron. J Mater Process Technol 213:560–573

Seah KHW, Sharma SC (1995) Machinability of alloyed austempered ductile iron. Int J Mach Tools Manuf 35:1475–1479

Arft M, Klocke F (2013) 14th CIRP conference on modeling of machining operations (CIRP CMMO), vol 8, pp 129–134

Bayati H, Elliot R (1995) Influence of austenitising temperature on mechanical properties of high manganese alloyed ductile iron. Mater Sci Technol 11:908–913

ASTM A897/A897M-15 (2015) Standard specification for austempered ductile iron castings. In: Annual book of ASTM standards, vol 01.02. ASTM International, West Conshohocken

ISO 3685: 1993 (E) (1993) Tool-life testing with single point tools

Manivel D, Gandhinathan R (2016) Optimization of surface roughness and tool wear in hard turning of austempered ductile iron (grade 3) using Taguchi method. Measurement 93:108–116

ISO 4287: 1997 Geometrical product specifications (GPS)—surface texture: profile method—terms, definitions and surface texture parameters

Junjun Cui and Liqing Chen (2015) Microstructures and mechanical properties of a wear-resistant alloyed ductile iron austempered at various temperatures. Metall Mater Trans A 46:3627–3634

Chawla V, Batra U, Puri D, Chawla A (2008) To study the effect of austempering temperature on fracture behaviour of Ni–Mo austempered ductile iron (ADI). J Miner Mater Charact Eng 7:307–316

Astakhov VP (2010) Surface integrity in machining. Springer, London

Çelik YH, Kilickap E, Güney M (2017) Investigation of cutting parameters affecting on tool wear and surface roughness in dry turning of Ti-6Al-4 V using CVD and PVD coated tools. J Braz Soc Mech Sci Eng 39:2085–2093

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Hegde, A., Sharma, S. Machinability study of manganese alloyed austempered ductile iron. J Braz. Soc. Mech. Sci. Eng. 40, 338 (2018). https://doi.org/10.1007/s40430-018-1258-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1258-6