Abstract

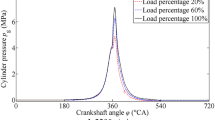

Connecting rod of an internal combustion engine is subjected to complex loading conditions. These mainly include the forces created through combustion in the combustion chamber of cylinder causing compression and bending of the connecting rod. This paper reports the results of a project objected to design the connecting rod of a heavy duty marine diesel engine and to modify its structural details based on finite element analysis. For this purpose, the initial design of the connecting rod was conducted by CATIA software and imported as stp file in Abaqus software. Results of the FEM model were utilized to modify the CAD model based on critical stress spots and magnitude of deformations of different sections of analyzed connecting rod model. Also, these results were used to introduce appropriate materials to tolerate the magnitude of forces developed under maximum combustion pressure of 190 bar. Further FEM analyses were carried out to modify the design in order to reduce the weight of final model of connecting rod. Results of finite element analysis of the final model revealed that the levels of stresses of the designed connecting rod are reduced significantly below the yield stresses of suggested materials for production of the connecting rod.

Similar content being viewed by others

References

Lee MK, Lee H, Lee TS, Jang H (2010) Buckling sensitivity of a connecting rod to the shank sectional area reduction. Mater Des 31:2796–2803

Pathade VC, Patle B, Ingale AN (2012) Stress analysis of I.C. engine connecting rod by FEM. IOSR J Mech Civ Eng 1:117–125

Wang Q, He F (2004) A review of developments in the forging of connecting rods in China. J Mater Process Technol 151:192–195

Khare S, Singh OP, Dora KB, Sasun C (2012) Spalling investigation of connecting rod. Eng Fail Anal 19:77–86

Griza S, Bertoni F, Zanon G, Reguly A, Strohaecker TR (2009) Fatigue in engine connecting rod bolt due to forming laps. Eng Fail Anal 16:1542–1548

Shaari MS, Rahman MM, Noor MM, Kadirgama K, Amirruddin AK (2010) Design of connecting rod of internal combustion engine: a topology optimization approach. In: National Conference in Mechanical Engineering Research and Postgraduate Studies (2nd NCMER), Malaysia, UMP Pekan, pp 155–166

Ramani HB, Kumar N, Kasundra PM (2012) Analysis of connecting rod under different loading condition using analysis software. Int J Innov Eng Res Technol 1(9):1–5

He BY, Shi GD, Sun JB, Chen S, Nie R (2013) Crack analysis on the toothed mating surfaces of a diesel engine connecting rod. Eng Fail Anal 34:443–450

4340 High tensile steel, Bõhler UDDEHOLM. http://www.bucorp.com/. Accessed 14 Feb 2012

Bolt grade markings and strength properties (2017). https://www.boltdepot.com/

Hu Z, Lynne K, Delfanian L (2015) Characterization of materials’ elasticity and yield strength through micro-/nano-indentation testing with a cylindrical flat-tip indenter. J Mater Res 30:578–591

Wang E, Nelson T, Rauch R (2004) Back to elements-tetrahedra vs. hexahedra. In: Proceedings of the 2004 international ANSYS conference

Cummins Inc., Columbus, USA (2016). https://cumminsengines.com/

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça.

Rights and permissions

About this article

Cite this article

Seyedzavvar, M., Seyedzavvar, M. Design of high duty diesel engine connecting rod based on finite element analysis. J Braz. Soc. Mech. Sci. Eng. 40, 59 (2018). https://doi.org/10.1007/s40430-018-0988-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-0988-9