Abstract

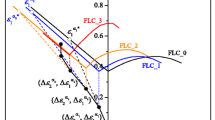

Since necking in some novel processes such as hydroforming and incremental forming can occur at locations where in addition to the in-plane stresses normal and through thickness shear stresses are exerted on the sheet metal, the plane stress assumption is not proper for predicting forming limits in these processes. Consequently in this research, conventional Marciniak-Kuczynski formability model has been generalized to consider all possible loading conditions including normal and through thickness shear stresses. For this purpose, additional force equilibrium and geometrical compatibility have been supposed between groove and matrix and Newton–Raphson trend has been applied for solving final system of equations in the numerical model to calculate limiting strains. In order to validate the theoretical model, subsequent theoretical forming limit curves have been compared with published experimental data. It has been shown that the extended M–K model is in good compatibility with experimental results and increase in normal and through thickness stresses enhances forming limits.

Similar content being viewed by others

References

Keeler SP, Backhofen WA (1963) Plastic instability and fracture in sheet stretched over rigid punches. ASM Trans 56:25–48

Keeler S (1968) Circular grid system—a valuable aid for evaluating sheet metal formability. SAE Paper 680092:1–9

Goodwin GM (1968) Application of strain analysis to sheet metal forming in the press shop. SAE Paper 680093

Sowerby R, Chakravarti PC (1983) The determination of the equivalent strain in finite, homogeneous deformation processes. J Strain Anal 18(2):119–123

Tan Z, Melin L, Magnusson C (1992) Application of an image processing technique in strain measurement in sheet metal forming. J Mat Proc Tech 33:299–310

Vacher P, Haddad A, Arrieux R (1999) Determination of the forming limit diagrams using image analysis by the correlation method. Ann ClRP 48(1):227–230

Geiger M, Merklein M (2003) Determination of forming limit diagrams—a new analysis method for characterization of materials formability. CIRP Ann - Manuf Technol 52(1):213–216

Marciniak Z, Kuczynski K (1967) Limit strains in the processes of stretch forming sheet steel. J Mech Phys Solids 1:609–620

Tadros AK, Mellor PB (1978) An experimental study of the in-plane stretching of sheet metal. Int J Mech Sci 20:121–134

Raghavan KS (1995) A simple technique to generate in-plane forming limit curves and selected applications. Metal Trans 26A:2075–2084

Hill R (1952) On discontinuous plastic states with special reference to localized necking in thin sheets. J Mech Phys Solids 1:19–30

Nakazima K, Kikuma T, Hasuka K (1972) Study on the formability of steel sheets, working group 1. In: 7th biennial congress IDDRG, Amsterdam

Giuliano G, Carrino L, Franchitti S (2005) Formability of superplastic PbSn60 alloy. Mater Lett 59:2156–2158

Kohara S (1993) Forming limit curves of aluminum and aluminum alloy sheets and effects of strain path on the curves. J Mater Proc Tech 38:723–753

Shakeri M, Sadough A, Dariani BM (2000) Effect of pre-straining and grain size on the limit strains in sheet metal forming. Proc IMechE Part B 214:821–827

Held C, Schleich R et al (2009) Investigation on the influence of combined shear load on the forming limit for high strength steels. Int J Mater Form 2:467–470

Shouler DR, Allwood JM (2010) Design and use of a novel sample design for formability testing in pure shear. J Mater Proc Tech 210:1304–1313

Hill R (1950) A theory of plastic bulging of a metal diaphragm by lateral pressure. Philos Mag Ser 7(41):1133–1142

Storen S, Rice JR (1975) Localized necking in thin sheets. J Mech Phys Solids 23:421–441

Gillis PP, Jones SE (1979) Tensile deformation of a flat sheet. Int J Mech Sci 21(2):109–117

Bressan JD, Williams JA (1983) The use of a shear instability criterion to predict local necking in sheet metal deformation. Int J Mech Sci 25:155–168

Boudeau N, Gelin JC, Salhi S (1998) Computational prediction of the localized necking in sheet forming based on microstructural material aspects. Comp Mat Sci 11(1):45–64

Hashiguchi K, Protasov A (2004) Localized necking analysis by the subloading surface model with tangential-strain rate and anisotropy. Int J Plast 20(10):1909–1930

Sowerby R, Duncan DL (1971) Failure in sheet metal in biaxial tension. Int J Mech Sci 13:217–229

Hutchinson JW, Neale KW (1977) Sheet necking II: time-independent behaviour. In: Koistinen DP, Wang N-M (eds) Mechanics of sheet metal forming: material behavior and deformation analysis GMR symposium. Plenum Press, New york, pp 127–153

Hecker SS (1972) A simple forming limit curve technique and results on aluminum alloys, sheet metal forming and formability. In: Proceedings of the 7th biennial congress of the IDDRG, Amsterdam, pp 5.1–5.8

Marciniak Z, Kuczynski K, Pokora T (1973) Influence of the plastic properties of a material on the sheet forming limit diagram for sheet metal in tension. Int J Mech Sci 15:789–805

Hutchinson JW, Neale KW (1977) Sheet necking III: strain-rate effects. In: Koistinen DP, Wang N-M (eds) Mechanics of sheet metal forming: material behavior and deformation analysis: GMR symposium. Plenum Press, New york, pp 269–285

Ghosh AK (1977) Plastic flow properties in relation to localized necking in sheets. In: Koistinen DP, Wang N-M (eds) Mechanics of sheet metal forming: material behavior and deformation analysis: GMR symposium. Plenum Press, New york, pp 287–312

Cao J, Yao H, Karafillis A (2000) Prediction of localized thinning in sheet metal using a general anisotropic yield criterion. Int J Plast 16(9):1105–1129

Barata da Rocha A, Barlat F, Jalinier JM (1984) Prediction of the forming limit diagram of anisotropic sheets in linear and nonlinear loading. Mater Sci Eng 68:151–164

McCarron TJ, Kain KE et al (1988) Effect of geometrical defects in forming sheet steel by biaxial stretching. Metall Trans A 19A:2067–2074

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—Yield criteria and flow rules for porous ductile media. J Eng Mater Tech 99(2):2–15

Tvergaard V, Needleman A (1984) Cup-cone fracture in a round tensile bar. Acta Metal 32(1):139–157

Regab AR, Saleh Ch, Zaafarani NN (2002) Forming limit diagram for kinematically hardened voided sheet metals. J Mater Proc Tech 128:302–312

Parmer A (1978) Mellor PB Prediction of limit strains in sheet metal using a more general yield criterion. Int J Mech Sci 20:385–391

Thomason CIA, Worswick MJ et al (1999) Modeling void nucleation and growth within periodic cluster of particles. Mech Phys Solids 47:1–26

Brunet Morestin (2001) Experimental and analytical necking studies of anisotropic sheet. Int J Mater Proc Tech 112:214–226

Azodi HD, Dariani BM (2003) Finding the optimum hill index in the determination of the forming limit diagram. Proc Mech Eng Part B 217:1677–1683

Gerdooei M, Dariani BM (2008) Strain-rate-dependent forming limit diagrams for sheet metals. Proc Mech Eng Part B 222:1651–1659

Knockaert R, Chastel Y, Massoni E (2002) Forming limits prediction using rate-independent polycrystalline plasticity. Int J Plast 18(2):231–247

Wu PD, McEwen SR et al (2004) Effect of cube texture on sheet metal formability. Mat Sci Eng A364(1–2):182–187

Makkouk R, Bourgeois N, Serri et al (2008) Experimental and theoretical analysis of the limits to ductility of type 304 stainless steel sheet. Eur J Mech A—Solids 27:181–194

Aretz H (2008) A simple isotropic-distortional hardening model and its application in elastic–plastic analysis of localized necking in orthotropic sheet metals. Int J Plast 24:1457–1480

Signorelli JW, Bertinetti MA, Turner PA (2009) Predictions of forming limit diagrams using a rate-dependent polycrystal self-consistent plasticity model. Int J Plast 25(1):1–25

Neil CJ, Agnew SR (2009) Crystal plasticity-based forming limit prediction for non-cubic metals: application to Mg alloy Az31b. Int J Plast 25(3):379–398

Ahmadi S, Eivani AR, Akbarzadeh A (2009) An experimental and theoretical study on the prediction of forming limit diagrams using new BBC yield criteria and MK analysis. Comp Mater Sci 44:1272–1280

Charca RG, Stout M et al (2010) Study of a drawing-quality sheet steel. II: forming limit curves by experiments and micromechanical simulations. Int J Sol Struct 47:2294–2299

Chung K, Ahn K et al (2011) Formability of TWIP (twinning induced plasticity) automotive sheets. Int J Plast 27:52–81

Barata da Rocha A, Santos AD et al (2009) Analysis of plastic flow localization under strain paths changes and its coupling with finite element simulation in sheet metal forming. J Mater Proc Tech 209:5097–5109

Yoshida K, Tadano Y, Kuroda M (2009) Improvement in formability of aluminum alloy sheet by enhancing geometrical hardening. Comput Mater Sci 46:459–468

Matin PH, Smith LM (2005) Practical limitations to the influence of through-thickness normal stress on sheet metal formability. Int J Plast 21:671–690

Assempour A, Nejadkhaki HK, Hashemi R (2010) Forming limit diagrams with the existence of through-thickness normal stress. Comput Mater Sci 48:504–508

Banabic D, Soare S (2008) On the effect of the normal pressure upon the forming limit strains. In: Hora P (Ed) Proceedings of the 7th international conference and workshop on numerical simulation of 3D sheet metal forming processes, pp 199–204. Interlaken, Switzerland

Wu PD, Embury JD et al (2009) Effects of superimposed hydrostatic pressure on sheet metal formability. Int J Plast 25:1711–1725

Eyckens P, Van Bael A, Van Houtte P (2009) Marciniak-Kuczynski type modelling of the effect of through-thickness shear on the forming limits of sheet metal. Int J Plast 25:2249–2268

Eyckens P, Van Bael A, Van Houtte P (2011) An extended Marciniak-Kuczynski model for anisotropic sheet subjected to monotonic strain paths with through-thickness shear. Int J Plast 27:1577–1597

Allwood JM, Shouler DR (2009) Generalized forming limit diagrams showing increased forming limits with non-planar stress states. Int J Plast 25:1207–1230

Stachowicz F (1988) Effect of annealing temperature on plastic flow properties and forming limit diagrams of titanium and titanium alloy sheets. Trans Jpn Inst Met 29:484–493

Sing WM, Rao KP (1995) Influence of material properties on sheet metal formability limits. J Mater Proc Tech 48:35–41

Hwang YM, Lin YK, Chuang HC (2009) Forming limit diagrams of tubular materials by bulge tests. J Mat Proc Tech 209:5024–5034

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Alexandre Mendes Abrao.

Rights and permissions

About this article

Cite this article

Fatemi, A., Dariani, B.M. The effect of normal and through thickness shear stresses on the formability of isotropic sheet metals. J Braz. Soc. Mech. Sci. Eng. 38, 119–131 (2016). https://doi.org/10.1007/s40430-015-0424-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-015-0424-3