Abstract

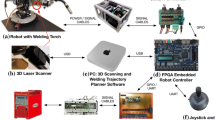

This paper presents the development of an FPGA-based platform for online discontinuity detection in a Gas Tungsten Arc Welding (GTAW) process, through the monitoring of its voltaic arc, using an optical infrared sensor. The FPGA-based platform uses a hardware/software co-design approach, in which the hardware part includes a change detection peripheral, apart from general purpose peripherals (e.g. UART, timer) and several customized ones such as memory for storing discontinuity data, timer and an ADC driver. The change detection peripheral comprises the filtering stage and the stopping rule stage, which include a Kalman filter and a cumulative sum (CUSUM) module, respectively. The overall system includes several processes running concurrently in the Microblaze embedded processor and several customized hardware modules, using floating point representation. In order to validate the FPGA-based platform, several experimental tests in the field have been done by introducing intentional discontinuities in the weld bead. These experimental results have shown a suitable performance of the overall system in the online discontinuity detection task. In this paper, the change detection peripheral is described as well as the synthesis results related to performance and resources consumption. In the overall co-design approach, the software part includes a MicroBlaze soft processor to control and manage the overall platform, including the interface issues.

Similar content being viewed by others

References

David SA, Babu SS, Vitek JM (2003) Welding. Encyclopedia of materials: science and technology, Elsevier, Oxford, pp 1–9. ISBN 978-0-08-043152-9. doi:10.1016/B0-08-043152-6/01889-1

Modenesi PJ, Marques PV. (2013) Soldagem I—Introdução aos processos de soldagem. Publicado por Anderson Vertuan. Belo Horizonte MG, p 53

Modenesi PJ (2001). Soldagem I—Descontinuidades e Inspeção em Juntas Soldas. Belo Horizonte, Universidade Federal de Minas Gerais Departamento de Engenharia Metalúrgica e de Materiais. Apostila Interna. p 29

Mirapeix J, Cobo A, Conde OM, Jaúregui C, López-Higuera JM (2006) Real-time arc welding defect detection technique by means of plasma spectrum optical analysis. NDT E Int 39(5):356–360. doi:10.1016/j.ndteint.2005.10.004

Sforza P, de Blasiis D (2002) On-line optical monitoring system for arc welding. NDT E Int 35(1):37–43. doi:10.1016/S0963-8695(01)00021-4

Hartenstein R, Kaiserslautern T (2007) Basics of reconfigurable computing. Designing embedded processors, Springer, Ed. Dordrecht, The Netherlands: Jörg Henkel and Sri Parameswaran, ch. 20, pp 451–501

Hurtado RH, Alfaro SCA, Llanos CH (2010) A methodology for on-line monitoring system in a welding process using FPGAs. Industrial Technology (ICIT), 2010 IEEE International Conference on, March 14–17 2010, pp 162–167. doi:10.1109/ICIT.2010.5472672

Gajski DD, Abdi S, Gerstlauer A, Schirner G (2009) Embedded system design, modeling. Synthesis and verification. Springer, New York

Göhringer D, Perschke T, Hübner M, Becker J (2009) A taxonomy of reconfigurable single-/multiprocessor systems-on-chip. Int J Reconfigurable Comput 395018:1–11. doi:10.1155/2009/395018

Knapp SK (1995) Using Programmable logic to accelerate DSP functions. Xilinx technical report, pp 1-8. Available at http://web.engr.oregonstate.edu/~sllu/fpga/dspintro.pdf

Göhringer D, Obie J, Braga ALS, Hübner M, Llanos CH, Becker J (2011) Exploration of the power-performance tradeoff through parameterization of FPGA-based multiprocessor systems. Int J Reconfigurable Comput 985931:1–17. doi:10.1155/2011/985931

Powell A, Savvas-Bouganis C, Cheung PYK (2013) High-level power and performance estimation of FPGA-based soft processors and its application to design space exploration. J Syst Arch 59(10):1144–1156. doi:10.1016/j.sysarc.2013.08.003

Huang C, Vahid F, Givargis T (2011) A custom FPGA processor for physical model ordinary differential equation solving. Emb Syst Lett IEEE 3(4):113–116. ISSN: 1943-0663. doi:10.1109/LES.2011.2170152

Nava F, Sciuto D, Santambrogio MD, Herbrechtsmeier S, Porrmann M, Witkowski U, Rueckert U (2011) Applying dynamic reconfiguration in the mobile robotics domain: a case study on computer vision algorithms. ACM Trans Reconfigurable Technol Syst 4:1–22. doi:10.1145/2000832.2000841

Shreejith S, Fahmy SA, Lukasiewycz M (2013). Reconfigurable computing in next-generation. Automot Netw Emb Syst Lett IEEE 5(1):12–15. ISSN: 1943–0663. doi:10.1109/LES.2013.2243698

Romero-Tronco DJ, Herrera-Ruiz HR, Terol-Villalobos I, Jáuregui-Correa JC (2004) FPGA based on-line tool breakage detection system for CNC milling machines. Mechatron Elsevier 4(4):439–454. doi:10.1016/S0957-4158(03)00069-2

Fung RF, Weng MH, Kung YS (2009) FPGA-based adaptive backstepping fuzzy control for a micro-positioning scott-russell mechanism. Mechan Syst Signal Process Elsevier 23(8):2671–2686. doi:10.1016/j.ymssp.2009.01.005

Trejo-Hernandez M, Osornio-Rios RA, Romero-Troncoso RDJ, Rodriguez-Donate C, Dominguez-Gonzalez A, Herrera-Ruiz G (2010) FPGA-based fused smart-sensor for tool-wear area quantitative estimation in CNC machine inserts. Sensors 10(4):3373–3388. doi:10.3390/s100403373

Maxfield C (2009) FPGAs. World Class Designs Newnes

Xilinx (2010) MicroBlaze Processor Reference Guide, ug081, vol 10.1, ed. 2010

Vera-Salas LA, Moreno-Tapia SV, Garcia-Perez A, Romero-Troncoso RDJ, Osornio-Rios RA, Serroukh I, Cabal-Yepez E (2011) FPGA-based smart sensor for online displacement measurements using a heterodyne Iinterferometer. Sensors 11:7710–7723. doi:10.3390/s110807710

Chang C, Ma KH, Yarn KF (2010) New frequency-tracking control method for ultrasound welding system by the FPGA Chip. Int J Phys Sci 5(13):2014–2019

Molino A, Martina M, Vacca F, Masera G, Terreno A, Pasquettaz G, D’Angelo G (2009) FPGA implementation of time–frequency analysis algorithms for laserwelding monitoring. Microprocess Microsyst Elsevier 33(3):179–190. doi:10.1016/j.micpro.2008.11.001

Rauma K, Luukko J, Härkönen T, Pajari I, Pyrhönen O (2005) A novel FPGA implementation of a welding control using a new bus architecture. In: Proceedings of the International Conference on Reconfigurable Computing and FPGAs (ReConFig 2005), IEEE, pp 1–4. doi:10.1109/RECONFIG.2005.6

Anzehaee MM, Haeri M (2012) A new method to control heat and mass transfer to work piece in a GMAW process. J Process Control 22(6):1087–1102. doi:10.1016/j.jprocont.2012.04.004

Bebiano D, Alfaro SA (2009) A weld defect detection system based on a spectrometer. Sensors 9(4):2851–2861. doi:10.3390/s90402851

Campbell S W, Galloway AM, McPherson NA (2012) Artificial neural network prediction of weld geometry performed using GMAW with alternating shielding gases. Weld J 91(6):174S–181S. ISSN 0043-2296

Shoeb M, Parvez M, Kumari P (2013). Effect of MIG welding input process parameters on weld bead geometry on HSLA steel. Int J Eng Sci Technol ISSN: 0975-5462, 5(01):200–212

Cayo EH, Alfaro, SCA (2012) Real-time assessment of the stability of metal transfer in GMAW-S process based on arc emissions. The 6th International Conference—Innovative technologies for joining advanced materials, vol 1, pp 1–4

Hurtado RH, Alfaro SCA, Llanos CH (2010) PFGA-based platform development for change detection in GTAW Welding Process. IEEE International Conference on Reconfigurable Computing and FPGAs (ReConFig), pp 61–66. doi:10.1109/ReConFig.2010.78

Gustafsson F (2000) Adaptative filtering and change detection. Wiley, New York

Grewal MS, Andrews AP (2001) Kalman filtering: theory and practic using Matlab. Second, Ed. Wiley, New York

Simon D. (2006) Optimal state estimation. Wiley, New York

Alfaro SA, Carvalho GC, da Cunha F (2006) A statistical approach for monitoring stochastic welding processes. J Mater Process Technol Achieve Mechan Mater Eng Elsevier 175(1–3):4–14. doi:10.1016/j.jmatprotec.2005.04.049

Franco FD (2008) Monitorização e localização de defeitos na soldagem TIG através do sensoriamento infravermelho. Master’s thesis, Universidade de Brasília. Faculdade de Tecnologia. Departamento de Engenharia Mecânica

TL-S, TL-GA (2004) User Manual. CALEX Electronics Ltd

Sánchez DF, Muñoz DM, Llanos CH, Ayala-Rincón M (2009) Parameterizable floating-point library for arithmetic operations in FPGAs. SBCCI ‘09. In: Proceedings of the 22nd Annual Symposium on Integrated Circuits and System Design, ACM, 2009, pp 253–258. doi:10.1145/1601896.1601948

Mentor Graphics, the ModelSim tutorial, available at http://model.com/

Digilent Inc; available at http://www.digilentinc.com/

Acknowledgments

This work was performed under the auspices of Brazilian Research Councils (CNPq and Capes) and sponsored by the University of Brasilia, UnB, Brasil.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Fernando Alves Rochinha.

Rights and permissions

About this article

Cite this article

Llanos, C.H., Hurtado, R.H. & Alfaro, S.C.A. FPGA-based approach for change detection in GTAW welding process. J Braz. Soc. Mech. Sci. Eng. 38, 913–929 (2016). https://doi.org/10.1007/s40430-015-0371-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-015-0371-z