Abstract

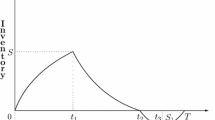

Nowadays, it is common for suppliers to be separated from their buyers by great distances. This means that, if some items in the lot turn out to be defective, the distance makes it uneconomical to order replacements from the original supplier. Moreover, both Type I and Type II errors may occur in the screening process for eliminating defective items and the combination of defective items and inspection errors may lead to shortages. Working with these assumptions, this paper develops two distinct models. Under the first model, defective items are repaired by a local repair shop subject to a repair charge and a mark-up margin. Under the second model, a local supplier replaces the defective with good ones, but at a higher cost. The expected total profit per cycle is developed, together with the expected cycle time, and, employing the renewal reward theorem, the objective function is derived, from which the optimum values are obtained for the order and shortage quantities. The paper presents numerical results and a discussion for both models. The study finds that repairing defective items generally leads to greater total profit than purchasing local replacements.

Similar content being viewed by others

References

Harris, F.W.: How many parts to make at once. Factory, Mag. Manag. 10(2), 135–136, 152 (1913): reprinted Oper. Res. 38, 947–950 (1990).

Shih, W.: Optimal inventory policies when stockouts result from defective products. Int. J. Prod. Res. 18(6), 677–686 (1980)

Porteus, E.L.: Optimal lot sizing, process quality improvement and setup cost reduction. Oper. Res. 34(1), 137–144 (1986)

Rosenblatt, M.J., Lee, H.L.: Economic production cycles with imperfect production processes. IIE Trans. 18(1), 48–55 (1986)

Lee, H.L., Rosenblatt, M.J.: Simultaneous determination of production cycle and inspection schedules in a production system. Manag. Sci. 33(9), 1125–1136 (1987)

Schwaller, R.L.: EOQ under inspection costs. Product. Inventory Manag. J. 29(3), 22–24 (1988)

Zhang, X., Gerchak, Y.: Joint lot sizing and inspection policy in an EOQ model with random yield. IIE Trans. 22(1), 41–47 (1990)

Cheng, T.C.E.: An economic order quantity model with demand-dependent unit production cost and imperfect production processes. IIE Trans. 23(1), 23–28 (1991)

Ben-Daya, M., Hariga, M.: Economic lot scheduling problem with imperfect production processes. J. Oper. Res. Soc. 51(7), 875–881 (2000)

Salameh, M.K., Jaber, M.Y.: Economic production quantity model for items with imperfect quality. Int. J. Prod. Econ. 64(1–3), 59–64 (2000)

Cárdenas-Barrón, L.E.: Observation on: “Economic production quantity model for items with imperfect quality”. Int. J. Prod. Econ. 67(2), 201 (2000)

Hayek, P.A., Salameh, M.K.: Production lot sizing with the reworking of imperfect quality items produced. Prod. Plan. Control 12, 584–590 (2001)

Chiu, Y.P.: Determining the optimal lot size for the finite production model with random defective rate, the rework process, and backlogging. Eng. Optim. 35(4), 427–437 (2003)

Chan, W.M., Ibrahim, R.N., Lochert, P.B.: A new EPQ model: integrating lower pricing, rework and reject situations. Prod. Plan. Control 14, 588–595 (2003)

Papachristos, S., Konstantaras, I.: Economic ordering quantity models for items with imperfect quality. Int. J. Prod. Econ. 100(1), 148–154 (2006)

Liao, G.L.: Optimal production correction and maintenance policy for imperfect process. Eur. J. Oper. Res. 182(3), 1140–1149 (2007)

Wee, H.M., Yu, J., Chen, M.C.: Optimal inventory model for items with imperfect quality and shortage backordering. Omega 35(1), 7–11 (2007)

Eroglu, A., Ozdemir, G.: An economic order quantity model with defective items and shortages. Int. J. Prod. Econ. 106(2), 544–549 (2007)

Maddah, B., Jaber, M.Y.: Economic order quantity for items with imperfect quality: revisited. Int. J. Prod. Econ. 112(2), 808–815 (2008)

Cárdenas-Barrón, L.E.: Economic production quantity with rework process at a single-stage manufacturing system with planned backorders. Comput. Ind. Eng. 57(3), 1105–1113 (2009)

Sana, S.S.: An economic production lot size model in an imperfect production system. Eur. J. Oper. Res. 201(1), 158–170 (2010)

Maddah, B., Salameh, M.K., Moussawi-Haidar, L.: Order overlapping: A practical approach for preventing shortages during screening. Comput. Ind. Eng. 58(4), 691–695 (2010)

Chang, H.C., Ho, C.H.: Exact closed-form solutions for “optimal inventory model for items with imperfect quality and shortage backordering. Omega 38(3–4), 233–237 (2010)

Chung, K.J.: The economic production quantity with rework process in supply chain management. Comput. Math. Appl. 62(6), 2547–2550 (2011)

Liao, G.L., Sheu, S.H.: Economic production quantity model for randomly failing production process with minimal repair and imperfect maintenance. Int. J. Prod. Econ. 130(1), 118–124 (2011)

Hsu, J.-T., Hsu, L.-F.: A note on “Optimal inventory model for items with imperfect quality and shortage backordering. Int. J. Ind. Eng. Comput. 3(5), 939–948 (2012)

Khan, M., Jaber, M.Y., Guiffrida, A.L., Zolfaghari, S.: A review of the extensions of a modified EOQ model for imperfect quality items. Int. J. Prod. Econ. 132(1), 1–12 (2011)

Jaber, M.Y., Zanoni, S., Zavanella, L.E.: Economic order quantity models for imperfect items with buy and repair options. Int. J. Prod. Econ. 155, 126–131 (2014)

Taleizadeh, A.A., Khanbaglo, M.P.S., Cárdenas-Barrón, L.E.: An EOQ inventory model with partial backordering and reparation of imperfect products. Int. J. Prod. Econ. 182, 418–434 (2016)

Li, N., Chan, F.T., Chung, S.H., Tai, A.H.: A stochastic production-inventory model in a two-state production system with inventory deterioration, rework process, and backordering. IEEE Trans. Syst. Man Cybern. Syst. 47(6), 916–926 (2017)

Skouri, K.: An EOQ model with backlog-dependent demand. Oper. Res. Int. Journal 18(2), 561–574 (2018)

Ross, S.: Probability and statistics for engineers and scientists. Elsevier Academic Press, Canada (2004)

Yoo, S.H., Kim, D., Park, M.S.: Economic production quantity model with imperfect-quality items, two-way imperfect inspection and sales return. Int. J. Prod. Econ. 121(1), 255–265 (2009)

Khan, M., Jaber, M.Y., Bonney, M.: An economic order quantity (EOQ) for items with imperfect quality and inspection errors. Int. J. Prod. Econ. 133(1), 113–118 (2011)

Hsu, L.-F.: A note on An economic order quantity (EOQ) for items with imperfect quality and inspection errors. Int. J. Ind. Eng. Comput. 3(4), 695–702 (2012)

Hsu, L.-F.: Erratum to “An economic order quantity (EOQ) for items with imperfect quality and inspection errors”. Int. J. Prod. Econ. 136(1), 253 (2012)

Hsu, J.-T., Hsu, L.-F.: Two EPQ models with imperfect production processes, inspection errors, planned backorders, and sales returns. Comput. Ind. Eng. 64(1), 389–402 (2013)

Glock, C.H., Jaber, M.Y.: A multi-stage production-inventory model with learning and forgetting effects, rework and scrap. Comput. Ind. Eng. 64(2), 708–720 (2013)

Khan, M., Jaber, M.Y., Ahmad, A.-R.: An integrated supply chain model with errors in quality inspection and learning in production. Omega 42(1), 16–24 (2014)

Mohammadi, B., Taleizadeh, A.A., Noorossana, R., Samimi, H.: Optimizing integrated manufacturing and products inspection policy for deteriorating manufacturing system with imperfect inspection. J. Manuf. Syst. 37(1), 299–315 (2015)

Zhou, Y., Chen, C., Li, C., Zhong, Y.: A synergic economic order quantity model with trade credit, shortages, imperfect quality and inspection errors. Appl. Math. Model. 40, 1012–1028 (2016)

Sarkar, B., Saren, S.: Product inspection policy for an imperfect production system with inspection errors and warranty cost. Eur. J. Oper. Res. 248(1), 263–271 (2016)

Cheikhrouhou, N., Sarkar, B., Ganguly, B., Malik, A.I., Batista, R., Lee, Y.H.: Optimization of sample size and order size in an inventory model with quality inspection and return of defective items. Ann. Oper. Res. 271(2), 445–467 (2018)

Yang, C.T., Ho, C.H., Lee, H.M., Ouyang, L.Y.: Supplier-retailer production and inventory models with defective items and inspection errors in non-cooperative and cooperative environments. RAIRO Oper. Res. 52(2), 453–471 (2018)

Dey, O., Giri, B.C.: A new approach to deal with learning in inspection in an integrated vendor-buyer model with imperfect production process. Comput. Ind. Eng. 131, 515–523 (2019)

Flapper, S.D.P., Fransoo, J.C., Broekmeulen, R.A.C.M., Inderfurth, K.: Planning and control of rework in the process industries: a review. Prod. Plan. Control 13(1), 26–34 (2002)

Duffuaa, S.O., Khan, M.: A general repeat inspection plan for dependent multicharacteristic critical components. Eur. J. Oper. Res. 191, 374–385 (2008)

Raouf, A., Jain, J.K., Sathe, P.T.: A cost-minimization model for multi characteristic component inspection. IIE Trans. 15(3), 187–194 (1983)

Duffuaa, S.O., Khan, M.: An optimal repeat inspection plan with several classifications. J. Oper. Res. Soc. 53(9), 1016–1026 (2002)

Duffuaa, S.O., Khan, M.: Impact of inspection errors on the performance measures of a general repeat inspection plan. Int. J. Prod. Res. 43(23), 4945–4967 (2005)

Khan, M., Ahmad, A.-R., Hussain, M.: Integrated decision models for a vendor–buyer supply chain with inspection errors and purchase and repair options. Int. J. Adv. Manuf. Technol. 104, 3221–3228 (2019)

Ross, S.M.: Introduction to Probability Models. Academic Press Inc., Cambridge (1989)

Duffuaa, S.O., Nadeem, I.A.: A complete inspection plan for dependent multicharacteristic critical components. Int. J. Prod. Res. 32(8), 1897–1907 (1994)

Lee, H.L.: On the optimality of a simplified multicharacteristic component inspection model. IIE Trans. 20(4), 392–398 (1988)

Buscher, U., Lindner, G.: Optimizing a production system with rework and equal sized batch shipments. Comput. Oper. Res. 34, 515–535 (2007)

Dorris, A. L., Hoag, L. L., Kasiviswanathan, G.: Inspector error models: an empirical investigation. In: Proceedings of the Human Factors Society 21st Annual Meeting, pp. 137–141 (1977). https://doi.org/10.1177/107118137702100211

Reddy, J.N.: An Introduction to the Finite Element Method. McGraw-Hill, New York (1993)

Hughes, T.J.R.: The Finite Element Method: Linear Static and Dynamic Finite Element Analysis. Prentice-Hall, Englewood Cliffs (1987)

Rao, S.S.: The Finite Element Method in Engineering. Elsevier Inc., Amsterdam (2011)

Lopes, R.: Integrated model of quality inspection, preventive maintenance and buffer stock in an imperfect production system. Comput. Ind. Eng. 126, 650–656 (2018)

Acknowledgements

The author is grateful for the valuable comments from the Editors and two anonymous reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Öztürk, H. Modelling Economic Order Quantities, Considering Buy and Repair Options for Defective Items, and Allowing for Shortages and Inspection Errors. J. Oper. Res. Soc. China 9, 757–795 (2021). https://doi.org/10.1007/s40305-021-00339-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40305-021-00339-8

Keywords

- Economic order quantity

- Inspection errors

- Optimization

- Gaussian numerical integration

- Shortages

- Repair/emergency purchase