Abstract

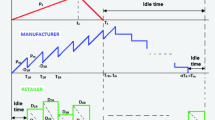

This paper explains an integrated production inventory supply chain model, which consists of a supplier, a manufacturer and a retailer under two-level credit period. One is manufacturer’s credit period offered by the supplier, and other is retailer’s credit period offered by the manufacturer. Here, the manufacturer replenishes raw materials from the supplier and produces non-deteriorating products in some cycles of equal length. It is noted that here four inventory structures have been considered to show the flow of the materials as either raw materials or finished products from supplier to retailer via manufacturer. Also in this model, manufacturer’s imperfect production has been considered. Here imperfect items are not repairable. The retailer receives good finished products from the manufacturer and sells these to his/her customers during some cycles of equal length in total time horizon. Our main objective is to find the optimal number of production and business cycles of the manufacturer such that the integrated system can get the maximum profit. The above discussed model is elaborated with the help of a numerical example, and a sensitivity analysis is done with respect to some parameters used in this model.

Similar content being viewed by others

Abbreviations

- \(A_\mathrm{m}\) :

-

Manufacturer’s ordering cost of raw material (per order) .

- \(A_\mathrm{r}\) :

-

Ordering cost for retailer (per order).

- \(C_\mathrm{hs}\) :

-

Supplier’s raw materials holding cost per unit time.

- \(C_\mathrm{mh}\) :

-

Manufacturer’s finished product holding cost per unit time.

- \(C_\mathrm{mr}\) :

-

Manufacturer’s raw material holding cost per unit item .

- \(C_\mathrm{ms}\) :

-

Screening cost of the manufacturer per unit produced product.

- \(C_\mathrm{p}\) :

-

Production cost of the manufacturer per unit finished product.

- \(C_\mathrm{rh}\) :

-

Retailer’s holding cost per unit time.

- \(C_\mathrm{s}\) :

-

Supplier purchase cost per unit item.

- \(C_1\) :

-

Manufacturer’s initial machinery setup cost.

- \(C_2\) :

-

Fixed process cost of manufacturer per cycle.

- \(D_\mathrm{r}\) :

-

Constant demand of the customer.

- EOQ:

-

Economic ordered quantity.

- EPQ:

-

Economic production quantity.

- \(I_\mathrm{e}\) :

-

Rate of interest earned per year.

- \(I_\mathrm{mb}\) :

-

Rate of interest paid for bank loan.

- \(I_\mathrm{p}\) :

-

Rate of interest payable per year.

- k :

-

Number of cycles (decision variable ), up to which manufacturer produces the item.

- M :

-

Manufacturer’s credit period given by supplier in years (\(M\leqslant T\)).

- MTP:

-

Manufacturer’s total profit.

- N :

-

Retailer’s credit period given by manufacturer in years (\(N\leqslant M\)).

- n :

-

No. of replenishment of the retailer (decision variable) .

- P :

-

Manufacturer’s production rate per unit time.

- \(Q_\mathrm{m}\) :

-

Quantity of raw materials purchased by manufacturer in each of the k cycles.

- \(Q_\mathrm{r}\) :

-

Order quantity of the retailer per cycle .

- S :

-

Supplier’s selling price of the raw materials per unit item.

- SCM:

-

Supply chain management.

- STP:

-

Supplier’s total profit.

- \(S_\mathrm{m}\) :

-

Unit selling price of the manufacturer.

- \(S_\mathrm{r}\) :

-

Unit selling price of the retailer.

- RTP:

-

Retailer’s total profit

- \(t_\mathrm{p}\) :

-

Production time of the manufacturer .

- \(\beta P\) :

-

Manufacturer’s perfect quality item production rate per unit time.

References

Banerjee, A.: A joint economic-lot-size for purchaser and vendor. Decis. Sci. 17, 292–311 (1986)

Zhang, X., Gerchak, Y.: Joint lotsizing and inspection policy in an EOQ model with random yield. IIE Trans. 22(1), 41–47 (1990)

Mondal, S.K., Maiti, M.: Multi-item fuzzy EOQ models using genetic algorithm. Comput. Ind. Eng. 44(1), 105–117 (2003)

Banu, A., Mondal, SK.: Analysis of credit linked demand in an inventory model with varying ordering cost. Springer plus, 5, 926. https://doi.org/10.1186/s40064-016-2567-9 (2016)

Manna, A.K., Dey, J.K., Mondal, S.K.: Imperfect production inventory model with production rate dependent defective rate and advertisement dependent demand. Comput. Ind. Eng. 104, 9–22 (2017)

Goyal, S.K.: An integrated inventory model for a single supplier-single customer problem. Int. J. Prod. Res. 15(1), 107–111 (1976)

Yang, C.P., Wee, M.H.: An integrated multi-lot-size production inventory model for deteriorating inventory item. Comput. Oper. Res. 30(5), 671–682 (2003)

Wee, H.M., Law, S.T.: An integrated production inventory model for ameliorating and deteriorating items taking account of time discounting. Math. Comput. Model. 43(5–6), 673–685 (2006)

Das, B.C., Das, B., Mondal, S.K.: Integrated supply chain model for deteriorating item with procurement cost dependent credit period. Comput. Ind. Eng. 64, 788–796 (2012)

Ouyang, L.Y., Wu, K.S., Ho, C.H.: An integrated vendor-buyer inventory model with quality improvement and lead time reduction. Int. J. Prod. Econ. 108, 349–358 (2007)

Das, B.C., Das, B., Mondal, S.K.: Optimal transportation and business cycles in an integrated production-inventory model with a discrete credit period. Transport. Res. E-Log. 68, 1–13 (2014)

Manna, A.K., Dey, J.K., Mondal, S.K.: Three-layer supply chain in an imperfect production inventory model with two storage facilities under fuzzy rough environment. J. Uncertain. Anal. Appl. 2(1), 17 (2014)

Das, B.C., Das, B., Mondal, S.K.: An integrated production inventory model under interactive fuzzycredit period for deteriorating item with several markets. Appl. Soft. Comput. 28, 453–465 (2015)

Das, B.C., Das, B., Mondal, S.K.: An integrated production-inventory model with defective item dependent stochastic credit period. Comput. Ind. Eng. 110, 255–263 (2017)

Goyal, S.K.: Economic order quantity under conditions of permissible delay in payments. J. Oper. Res. Soc. 36(4), 335–338 (1985)

Aggarwal, S.P., Jaggi, C.K.: Ordering policies of deteriorating items under permissible delay in payment. J. Oper. Res. Soc. 46, 658–662 (1995)

Chu, P., Chung, S.P., Lan, S.P.: Economic order quantity of deteriorating items under permissible delay in payments. Comput. Oper. Res. 25, 817–824 (1998)

Chung, K.J.: The inventory replenishment policy for deteriorating items under permissible delay in payments. Comput. Ind. Eng. 37, 267–281 (2000)

Huang, Y.F.: Optimal retailer’s replenishment policy for the EPQ model under the supplier’s trade credit policy. Prod. Plan. Control 15, 27–33 (2004)

Krichen, S., Laabidi, A., Abdelaziz, F.B.: Single supplier multiple cooperative retailer’s inventory model with quality discount and permissible delay in payments. Comput. Ind. Eng. 60, 164–172 (2011)

Abad, P.L., Jaggi, C.K.: A joint approach for setting unit price and the length of the credit period for a seller when end demand is price sensitive. Int. J. Prod. Econ. 83, 115–122 (2003)

Huang, Y.F.: Optimal retailers ordering policies in the EOQ model under trade credit financing. J. Oper. Res. Soc. 54, 1011–1015 (2003)

Ho, C.H.: The optimal integrated inventory policy with price—and—credit lined demand under two level trade credit. Comput. Ind. Eng. 60, 117–126 (2011)

Min, J., Zhou, Y.W., Zhao, J.: An inventory model for deteriorating items under stock dependent demand and tw level trade credit. Appl. Math. Model. 34, 3273–3285 (2010)

Huang, Y.F.: An inventory model under two level of trade credit and limited storage space derived without derivatives. Appl. Math. Model. 30, 418–436 (2006)

Sana, S.S., Chaudhuri, K.S.: A deterministic EOQ model with delays in payments and price-discount offers. Eur. J. Oper. Res. 184, 509–533 (2008)

Teng, J.T., Yang, H.L., Chern, M.S.: An inventory model for increasing demand under two levels of trade credit linked to order quantity. Appl. Math. Model. 37, 7624–7632 (2013)

Rosenblatt, M.J., Lee, H.L.: Economic production cycles with imperfect production processes”. IIE Trans. 18, 48–55 (1986)

Salameh, M.K., Jaber, M.Y.: Economic production quantity model for items with imperfect quality”. Int. J. Prod. Econ. 64, 59–64 (2000)

Cheng, T.C.E.: An economic order quantity model with demand-dependent unit production cost and imperfect production processes. IIE Trans. 23, 23–28 (1991)

Lin, C.S., Chen, C.H., Kroll, D.E.: Integrated production-inventory models for imperfect production processes under inspection schedules. Comput. Ind. Eng. 44, 633–650 (2003)

Manna, A.K., Dey, J.K., Mondal, S.K.: Two layers supply chain in an imperfect production inventory model with two storage facilities under reliability consideration. J. Ind. Prod. Eng. 35, 57–73 (2018)

Ganesan, T., Vasant, P., Elamvazuthi, I.: Advances in Metaheuristics: Applications in Engineering Systems, 1st Edition, CRC Press, (2016)

Vasant, P., Zelinka, I., Weber, GW.: Intelligent Computing & Optimization. Conference proceedings ICO 2018, Springer, Cham. (2018)

Acknowledgements

The authors thank the honorable reviewers for their valuable comments to improve the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research work was supported by Council of Scientific and Industrial Research, Human Resource Development Group, India (No. 25(0276)/17/EMR-II).

Appendix

Appendix

Some important terms are succinctly defined through the following discussions:

Supply chain management (SCM):

A supply chain is a system of organizations, people, activities, information and resources involved in moving a product or service from supplier to customer. In the 1980s, the term supply chain management (SCM) was developed to express the need to integrate the key business processes, from end user through original suppliers. The basic idea behind SCM is that companies and corporations involve themselves in a supply chain by exchanging information about market fluctuations and production capabilities.

Economic order quantity (EOQ) model:

In inventory management, economic order quantity (EOQ) is the order quantity that minimizes the total holding costs and ordering costs.

Economic production quantity (EPQ) model:

The economic production quantity (EPQ) model determines the quantity a company or a retailer should order to minimize the total inventory costs by balancing the inventory holding cost and average fixed ordering cost. The difference between the EOQ model and EPQ model is that the EPQ model assumes the company will produce its own quantity, while the EOQ model assumes the quantity is produced by another company.

Integrated inventory system:

When an inventory model is studied from the viewpoint of supply chain management regarding the supplier and manufacturer and other supply chain partners jointly to create a production or ordering strategies that are mutually beneficial and shares information completely in order to achieve the maximum profit or minimum cost of the system is known as integrated inventory system.

Two-level credit period:

In a supply chain system, when it is observed that there is trade credit facility under two stages of the supply chain members, then such type of credit facility is known as two-level trade credit policy. For example, suppose a supplier offers a credit period to the manufacturer and manufacturer also offers a credit period to his/her retailer, then it is a two-level credit policy under a supplier–manufacturer–retailer supply chain system.

Rights and permissions

About this article

Cite this article

Panja, S., Mondal, S.K. Analytics of an Imperfect Four-Layer Production Inventory Model Under Two-Level Credit Period Using Branch-and-Bound Technique. J. Oper. Res. Soc. China 10, 725–748 (2022). https://doi.org/10.1007/s40305-020-00300-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40305-020-00300-1

Keywords

- Supply chain

- Integrated production inventory

- Four-layer inventory system

- Imperfect production

- Two-level credit period