Abstract

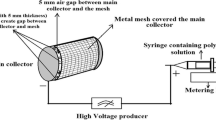

Tissue engineering opens a new horizon for biological tissue replacement applications. Scaffolds, appropriate cells, and signaling induction are the main three determinant parameters in any tissue engineering applications. Designing a suitable scaffold which can mimic the cellular inherent and natural habitation is of great importance for cellular growth and proliferation. Just like a natural extracellular matrix (ECM), scaffolds provide the cells with an environment for performing biological functions. Accordingly, vast surface area and three-dimensional nanofibrous structures are among the pivotal characteristics of functional scaffolds in tissue engineering, and enhancement of their properties is the main purpose of the present research. In our previous study, a patterned structure composed of continuous nanofibers and microparticles was introduced. In this work, a new modification is applied for adjustment of the surface area of an electrospun/electrosprayed scaffold. For this purpose, at predetermined stages during electrospinning/electrospraying, the nitrogen gas is flushed through the mesh holes of the collector in the opposite direction of the jet movement. This method has led to the formation of very thin nanofibrous layers at nitrogen flush intervals by providing a cooling effect of the sweeping nitrogen. As a consequence, a straticulated structure has been fabricated which possesses extremely high surface/volume ratio. The porosity, water absorption, and morphological analysis were conducted on the obtained scaffold. In vitro cytocompatibility assessments as well as histological analysis demonstrated that the fabricated scaffold provides a proper substrate for cellular attachment, proliferation and infiltration. These findings can be advantageous in three-dimensional tissue engineering such as bone tissue engineering applications. Furthermore, according to the advanced microstructure and vast surface area of the fabricated samples, they can be applied in many other applications, such as membrane, filtration, etc.

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

Buttafoco L, Kolkaman NG, Engbers-Buijtenhuijs P, Poot AA, Dijkstra PJ, Vermes I, Feijen J (2006) Electrospinning of collagen and elastin for tissue engineering applications. Biomaterials 27(5):724–734

Collins MN, Ren G, Young K, Pina S, Reis RL, Oliveira JM (2021) Scaffold fabrication technologies and structure/function properties in bone tissue engineering. Adv Funct Mat 31(21):202010609. https://doi.org/10.1002/adfm.202010609

Daraeinejad Z, Shabani I (2021) Enhancing cellular infiltration on fluffy polyaniline-based electrospun nanofibers. Front Bioeng Biotechnol 9:641371. https://doi.org/10.3389/fbioe.2021.641371

Deng A, Yang Y, Du S (2021) Tissue engineering 3D porous scaffolds prepared from electrospun recombinant human collagen (RHC) polypeptides/chitosan nanofibers. Appl Sci 11:5096. https://doi.org/10.3390/app11115096

Giannoudis PV, Dinopoulos H, Tsiridis E (2005) Bone substitutes: an update. Injury 36(3):S20–S27

Han S, Nie K, Li J, Sun Q, Wang X, Li X, Li Q (2021) 3D Electrospun nanofiber-based scaffolds: from preparations and properties to tissue regeneration applications. Stem Cell Int. https://doi.org/10.1155/2021/8790143

Hejazi F, Mirzadeh H (2016a) Novel 3D scaffold with enhanced physical and cell response properties for bone tissue regeneration, fabricated by patterned electrospinning/electrospraying. J Mater Sci Mater Med 27(9):1–17

Hejazi F, Mirzadeh H (2016b) Roll-designed 3D nanofibrous scaffold suitable for the regeneration of load bearing bone defects. Prog Biomater 5(3–4):199–211

Hejazi F, Mirzadeh H, Contessi N, Tanzi MC, Fare S (2017) Novel class of collector in electrospinning device for the fabrication of 3D nanofibrous structure for large defect load-bearing tissue engineering application. J Biomed Mater Res Part A 105(5):1535–1548

Hejazi F, Bagheri S, Olov N, Zeini D, Solouk A, Mirzadeh H (2021a) Fabrication of nanocomposite/nanofibrous functionally graded biomimetic scaffolds for osteochondral tissue regeneration. J Biomed Mat Res Part A 109(9):1657–1669. https://doi.org/10.1002/jbm.a.37161

Hejazi F, Ebrahimi V, Asgary M, Piryaei A, Fridoni MJ, Kermani AA, Zare F, Abdollahifar MA (2021b) Improved healing of critical-size femoral defect in osteoporosis rats model using 3D Elastin/Polycaprolactone/nHA scaffold in combination with mesenchymal stem cells. J Mater Sci Mater Med 32(3):27. https://doi.org/10.1007/s10856-021-06495-w

Hodge J, Quint C (2019) The improvement of cell infiltration in an electrospun scaffold with multiple synthetic biodegradable polymers using sacrificial PEO microparticles. J Biomed Mater Res A 107(9):1954–1964. https://doi.org/10.1002/jbm.a.36706

Khorshidi S, Solouk A, Mirzadeh H, Mazinani S, Lagaron JM, Sharifi S, Ramakrishna S (2016) A review of key challenges of electrospun scaffolds for tissue-engineering applications. J Tissue Eng Regen Med 10(9):715–738

Koyyada A, Orsu P (2021) Recent advancements and associated challenges of scaffold fabrication techniques in tissue engineering applications. Regen Eng Transl Med 7:147–159

Kumar M, Sharma V (2021) Additive manufacturing techniques for the fabrication of tissue engineering scaffolds: a review. Rapid Prototyp J 27(6):1230–1272. https://doi.org/10.1108/RPJ-01-2021-0011

Lee JB, Ko YG, Cho D, Park WH, Kwon OH (2017) Modification and optimization of electrospun gelatin sheets by electron beam irradiation for soft tissue engineering. Biomater Res 21:17. https://doi.org/10.1186/s40824-017-0100-z

Mao Z, Fan B, Wang X, Huang X, Guan J, Sun Z, Xu B, Yang M, Chen Z, Jiang D, Yu J (2021) A systematic review of tissue engineering scaffold in tendon bone healing in vivo. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2021.621483

Nguyen LT, Liao S, Chan CK, Ramakrishna S (2012) Enhanced osteogenic differentiation with 3D electrospun nanofibrous scaffolds. Nanomedicine (lond) 7(10):1561–1575

Pham QP, Sharma U, Mikos AG (2006) Electrospinning of polymeric nanofibers for tissue engineering applications: a review. Tissue Eng 12(5):1197–1211

Pina S, Oliveira JM, Reis RL (2015) Natural-based nanocomposites for bone tissue engineering and regenerative medicine: a review. Adv Mater 27(7):1143–1169

Riha SM, Maroof M, Fauzi MB (2021) Synergistic effect of biomaterial and stem cell for skin tissue engineering in cutaneous wound healing: a concise review. Polymers (basel) 13(10):1546. https://doi.org/10.3390/polym13101546

Rnjak-Kovacina J, Weiss AS (2011) Increasing the pore size of electrospun scaffolds. Tissue Eng Part B Rev 17(5):365–372

Sell SA, Wolfe PS, Ericksen JJ, Simpson DG, Bowlin GL (2011) Incorporating platelet-rich plasma into electrospun scaffolds for tissue engineering applications. Tissue Eng Part A 17:2723–2737. https://doi.org/10.1089/ten.tea.2010.0663

Sill TJ, von Recum HA (2008) Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29(13):1989–2006

Staehlke S, Rebl H, Nebe B (2019) Phenotypic stability of the human MG-63 osteoblastic cell line at different passages. Cell Bio Int 43(1):22–32. https://doi.org/10.1002/cbin.11073

Stampoultzis T, Karami P, Pioletti DP (2021) Thoughts on cartilage tissue engineering: a 21st century perspective. Curr Res Transl Med 69(3):103299

Szentivanyi A, Chakradeo T, Zernetsch H, Glasmacher B (2011) Electrospun cellular microenvironments: understanding controlled release and scaffold structure. Adv Drug Deliv Rev 63(4–5):209–220

Tupone MG, d’Angelo M, Castelli V, Catanesi M, Benedetti E, Cimini A (2021) A state-of-the-art of functional scaffolds for 3D nervous tissue regeneration. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2021.639765

Vacanti JP, Langer R (1999) Tissue engineering: the design and fabrication of living replacement devices for surgical reconstruction and transplantation. Lancet 354:S32–S34

Vonbrunn E, Mueller M, Pichlsberger M, Sundl M, Helmer A, Wallner SA, Rinner B, Tuca A-C, Kamolz L-P, Brislinger D, Glasmacher B, Lang-Olip I (2020) Electrospun PCL/PLA scaffolds are more suitable carriers of placental mesenchymal stromal cells than collagen/elastin scaffolds and prevent wound contraction in a mouse model of wound healing. Front Bioeng Biotech 8:604123. https://doi.org/10.3389/fbioe.2020.604123

Wu L, Ding J (2004) In vitro degradation of three-dimensional porous poly (D, L-lactide-co-glycolide) scaffolds for tissue engineering. Biomaterials 25(27):5821–5830

Xu B (1996) Measurement of pore characteristics in nonwoven fabrics using image analysis. Cloth Text Res J 14(1):81–88

Ziabari M, Mottaghitalab V, Haghi AK (2008) Evaluation of electrospun nanofiber pore structure parameters. Kor J Chem Eng 25(4):923–932

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hejazi, F., Mirzadeh, H. & Shojaei, S. PCL-based 3D nanofibrous structure with well-designed morphology and enhanced specific surface area for tissue engineering application. Prog Biomater 12, 113–122 (2023). https://doi.org/10.1007/s40204-022-00215-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40204-022-00215-5