Abstract

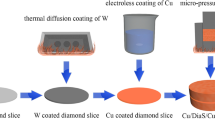

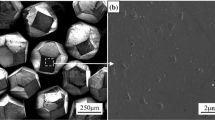

Diamond has poor interface tolerance with Al. To enhance interface bonding, in this study, tungsten carbide (WC) nanocoatings on the surface of diamond particles were prepared using sol–gel and in-situ reaction methods. WO3 sol–gel with two concentrations, 0.2 mol/L, and 0.5 mol/L, was, respectively, coated on diamond particles, then sintered at 1250 °C for 2 h to produce WC nanocoatings. The concentration of 0.2 mol/L WO3 sol–gel was not enough to cover the surface of the diamond completely, while 0.5 mol/L WO3 sol–gel could fully cover it. Moreover, WO3 was preferentially deposited on {100} planes of the diamond. WO3 converted to WC in-situ nanocoatings after sintering due to the in-situ reaction of WO3 and diamond. The diamond-reinforced Al composites with and without WC coating were fabricated by powder metallurgy. The diamond/Al composite without coating has a thermal conductivity of 584.7 W/mK, while the composite with a coating formed by 0.2 mol/L and 0.5 mol/L WO3 sol–gel showed thermal conductivities of 626.1 W/mK and 584.2 W/mK, respectively. The moderate thickness of nanocoatings formed by 0.2 mol/L WO3 sol–gel could enhance interface bonding, therefore improving thermal conductivity. The nanocoating produced by 0.5 mol/L WO3 sol–gel cracked during the fabrication of the composite, leading to Al12W formation and a decrease in thermal conductivity.

Similar content being viewed by others

References

A.M. Abyzov, S.V. Kidalov, F.M. Shakhov, J. Mater. Sci. 46, 1424 (2011)

K. Yoshida, H. Morigami, Microelectron. Reliab. 44, 303 (2004)

A.L. Moore, L. Shi, Mater. Today 17, 163 (2014)

J.D. Mathias, P.M. Geffroy, J.F. Silvain, Appl. Therm. Eng. 29, 2391 (2009)

T.H. Nam, G. Requena, P. Degischer, Compos. Part A Appl. Sci. Manuf. 39, 856 (2008)

C. Xue, J.K. Yu, X.M. Zhu, Mater. Des. 32, 4225 (2011)

Y. Yamamoto, T. Imai, K. Tanabe, T. Tsuno, Y. Kumazawa, N. Fujimori, Diam. Relat. Mater. 6, 1057 (1997)

L. Wei, P.K. Kuo, R.L. Thomas, T.R. Anthony, W.F. Banholzer, Phys. Rev. Lett. 70, 3764 (1993)

Y. Zhang, J.W. Li, L.L. Zhao, X.T. Wang, J. Mater. Sci. 50, 688 (2015)

W.L. Yang, K. Peng, J.J. Zhu, D.Y. Li, L.P. Zhou, Diam. Relat. Mater. 46, 35 (2014)

C.Y. Guo, X.B. He, S.B. Ren, X.H. Qu, J. Alloy. Compd. 664, 777 (2016)

C. Edtmaier, J. Segl, E. Rosenberg, G. Liedl, R. Pospichal, A. Steiger-Thirsfeld, J. Mater. Sci. 53, 15514 (2018)

C. Azina, I. Cornu, J.F. Silvain, Y.F. Lu, J.L. Battaglia, AIP Adv. 9, 055315 (2019)

W.S. Yang, G.Q. Chen, P.P. Wan, J. Qiao, F.J. Hu, S.F. Liu, Q. Zhang, M. Hussain, R.H. Dong, G.H. Wu, J. Alloy. Compd. 726, 623 (2017)

Z.Q. Tan, G. Ji, A. Addad, Z.Q. Li, J.F. Silvain, D. Zhang, Compos. Part A Appl. Sci. Manuf. 91, 9 (2016)

X.Y. Liu, W.G. Wang, D. Wang, D.R. Ni, L.Q. Chen, Z.Y. Ma, Mater. Chem. Phys. 182, 256 (2016)

G. Ji, Z.Q. Tan, Y.G. Lu, D. Schryvers, Z.Q. Li, D. Zhang, Mater. Charact. 112, 129 (2016)

Z. Tan, Z. Li, G. Fan, Q. Guo, X. Kai, G. Ji, L. Zhang, D. Zhang, Mater. Des. 47, 160 (2013)

Y. Zhang, H.L. Zhang, J.H. Wu, X.T. Wang, Scr. Mater. 65, 1097 (2011)

S. Ren, X. Shen, C. Guo, N. Liu, J. Zang, X. He, X. Qu, Compos. Sci. Technol. 71, 1550 (2011)

L. Wang, J. Li, M. Catalano, G. Bai, N. Li, J. Dai, X. Wang, H. Zhang, J. Wang, M.J. Kim, Compos. Part A Appl. Sci. Manuf. 113, 76 (2018)

G. Chang, F.Y. Sun, J.L. Duan, Z.F. Che, X.T. Wang, J.G. Wang, M.J. Kim, H.L. Zhang, Acta Mater. 160, 235 (2018)

C. Xue, J.K. Yu, Emerg. Mater. Res. 1, 99 (2012)

L.H. Wang, J.W. Li, Z.F. Che, X.T. Wang, H.L. Zhang, J.G. Wang, M.J. Kim, J. Alloys Compd. 749, 1098 (2018)

Y. Pan, X. He, S. Ren, M. Wu, X. Qu, Materials 12, 475 (2019)

Y.H. Sun, C. Zhang, L.K. He, Q.N. Meng, B.C. Liu, K. Gao, J.H. Wu, Sci. Rep. 8, 1 (2018)

X. Li, W. Yang, J. Sang, J. Zhu, L. Fu, D. Li, L. Zhou, J. Alloy. Compd. 846, 156258 (2020)

W.L. Yang, J.Q. Sang, L.P. Zhou, K. Peng, J.J. Zhu, D.Y. Li, Diam. Relat. Mater. 81, 127 (2018)

N. Li, L. Wang, J. Dai, X. Wang, J. Wang, M.J. Kim, H. Zhang, Diam. Relat. Mater. 100, 107565 (2019)

D.P.H. Hasselman, L.F. Johnson, J. Compos. Mater. 21, 508 (1987)

V. Sinha, J.E. Spowart, J. Mater. Sci. 48, 1330 (2013)

L.H. Wang, J.W. Li, G.Z. Bai, N. Li, X.T. Wang, H.L. Zhang, J.G. Wang, M.J. Kim, J. Alloy. Compd. 781, 800 (2019)

M.Y. Yuan, Z.Q. Tan, G.L. Fan, D.B. Xiong, Q. Guo, C.P. Guo, Z.Q. Li, D. Zhang, Diam. Relat. Mater. 81, 38 (2018)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51931009) and the Liaoning Revitalization Talents Program (No. XLYC2007009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, Z.Y., Wang, D., Wang, W.G. et al. Effect of Nanometer WC Coating on Thermal Conductivity of Diamond/6061 Composites. Acta Metall. Sin. (Engl. Lett.) 36, 118–126 (2023). https://doi.org/10.1007/s40195-022-01450-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-022-01450-2