Abstract

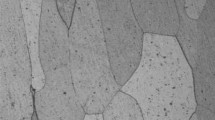

The influences of initial grain size (IGS) with 20 µm and 50 µm on the hot flow behavior and microstructural changes of pure copper were investigated using hot compression tests at a temperature range of 623–1073 K and strain rate range of 0.001–0.1 s−1. The effects of critical stress and corresponding critical strain were studied based on the internal and external processing parameters. The critical stress and strain decreased with increasing temperature and decreasing strain rate. The investigation results of the microstructure and true strain–stress diagrams showed that dynamic recovery, dynamic recrystallization (DRX), and twinning mechanisms were caused during the hot deformation of pure copper. Microstructure evolution indicated some DRXed fine-grain took place around grain boundary of hot deformed samples with IGS of 20 µm whereas DRXed fine-grain took place in interior grains for samples with larger IGS. The results also showed that grain growth is also dependent on IGS as the grain growth rate for samples with the larger IGS is greater than the smaller IGS. The critical strain rate and the temperature were obtained at 0.01 s−1 and 973 K, respectively, for the sudden change in the grain growth rate. Also, twinning highly depended on IGS which almost did not happen in fine grain size while the volume fraction of twinning increased with increasing grain size.

Similar content being viewed by others

References

W.H. Tian, A.L. Fan, H.Y. Gao, J. Luo, Z. Wang, Mater. Sci. Eng. A 350, 160 (2003)

J.Y. Yang, W.J. Kim, J. Mater. Res. Technol. 9, 960 (2020)

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Prog. Mater. Sci. 60, 130 (2014)

S. Sakui, T. Sakai, K. Takeishi, Trans. Iron Steel Inst. Jpn. 17, 718 (1977)

H.J. McQueen, J.J. Jonas, Recovery and Recrystallization during High Temperature Deformation, in Plastic Deformation of Materials. ed. by R.J. Arsenault (Elsevier, Amsterdam, 1975), pp. 393–493

Y. Liu, W. Xiong, Q. Yang, J.W. Zeng, W. Zhu, G. Sunkulp, J. Mater. Eng. Perform. 27, 1812 (2018)

S.H. Huang, D.Y. Shu, C.K. Hu, S.F. Zhu, Trans. Nonferrous Met. Soc. China (Engl. Ed.) 26, 1044 (2016)

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, L.T. Li, J. Alloys Compd. 640, 101 (2015)

G. Liu, W. Xie, A. Hadadzadeh, G. Wei, Z. Ma, J. Liu, Y. Yang, W. Xie, X. Peng, M. Wells, J. Alloys Compd. 766, 460 (2018)

B. Song, N. Guo, T. Liu, Q.S. Yang, Mater. Des. 62, 352 (2014)

F.Z. Hassani, M. Ketabchi, M.T. Hassani, J. Mater. Sci. 46, 7689 (2011)

R. Gehrmann, M.M. Frommert, G. Gottstein, Mater. Sci. Eng. A 395, 338 (2005)

F. Guo, D. Zhang, X. Fan, J. Li, L. Jiang, F. Pan, Mater. Sci. Eng. A 655, 92 (2016)

Y.T. Zhu, X.Z. Liao, X.L. Wu, J. Narayan, J. Mater. Sci. 48, 4467 (2013)

C.H. Park, C.S. Oh, S. Kim, Mater. Sci. Eng. A 542, 127 (2012)

A. Berger, P.J. Wilbrandt, F. Ernst, U. Klement, P. Haasen, Prog. Mater. Sci. 32, 1 (1988)

S.W. Wang, H.W. Song, Y. Chen, S.H. Zhang, H.H. Li, Acta Metall. Sin. (Engl. Lett.) 33, 1618 (2020)

Y.H. Zhao, Z. Horita, T.G. Langdon, Y.T. Zhu, Mater. Sci. Eng. A 474, 342 (2008)

Y.T. Zhu, X.Z. Liao, X.L. Wu, Prog. Mater. Sci. 57, 1 (2012)

X.J. Wang, X.J. Sun, C. Song, H. Chen, S. Tong, W. Han, F. Pan, Acta Metall. Sin. (Engl. Lett.) 32, 746 (2019)

M.A. Meyers, U.R. Andrade, A.H. Chokshi, Metall. Mater. Trans. A 26, 2881 (1995)

Q. Yang, M. Ma, Y. Tan, S. Xiang, F. Zhao, Y. Liang, Metals (Basel) 9, 891 (2019)

Y. Yang, Z. Zhang, X. Li, Q. Wang, Y. Zhang, Mater. Des. 51, 592 (2013)

H. Ahmadi, H.R. Rezaei Ashtiani, M. Heidari, Mater. Today Commun. 25, 101528 (2020)

H.R.R. Ashtiani, A.A. Shayanpoor, Trans. Nonferrous Met. Soc. China 31, 345 (2021)

A.M. Wusatowska-Sarnek, H. Miura, T. Sakai, Mater. Sci. Eng. A 323, 177 (2002)

M.A. Meyers, O. Vöhringer, V.A. Lubarda, Acta Mater. 49, 4025 (2001)

G. Liang, Y. Ali, G. You, M.X. Zhang, Materialia 3, 113 (2018)

Y. Ali, G. You, F. Pan, M.X. Zhang, Mater. Trans. A Phys. Metall. Mater. Sci. 48, 474 (2017)

J. Dai, M.A. Easton, M. Zhang, D. Qiu, X. Xiong, W. Liu, G. Wu, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 45, 4665 (2014)

H. Miura, M. Ozama, R. Mogawa, T. Sakai, Scr. Mater. 48, 1501 (2003)

H. Beladi, P. Cizek, P.D. Hodgson, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 40, 1175 (2009)

H. Mirzadeh, J.M. Cabrera, A. Najafizadeh, P.R. Calvillo, Mater. Sci. Eng. A 538, 236 (2012)

P.D. Littlewood, T.B. Britton, A.J. Wilkinson, Acta Mater. 59, 6489 (2011)

H.R. Rezaei Ashtiani, P. Shahsavari, Trans. Nonferrous Met. Soc. China 30, 2927 (2020)

B. Verlinden, J. Driver, I. Samajdar, R. Doherty, Thermo-Mechanical Processing of Metallic Materials, n.d.

R. Ding, Z.X. Guo, Acta Mater. 49, 3163 (2001)

Y.Q. Jiang, Y.C. Lin, G.Q. Wang, G.D. Pang, M.S. Chen, Z.C. Huang, J. Alloys Compd. 870, 159534 (2021)

H.J. Frost, M.F. Ashby, Deformation Mechanism Maps: The Plasticity and Creep of Metals and Ceramics (Pergamon press, Oxford, 1982)

M.R. Barnett, Z. Keshavarz, A.G. Beer, D. Atwell, Acta Mater. 52, 5093 (2004)

H.R. Rezaei Ashtiani, A.A. Shayanpoor, Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-020-00943-y

T. Hirata, T. Osa, H. Hosokawa, K. Higashi, Mater. Trans. 43, 2385 (2002)

H.R. Rezaei Ashtiani, M.H. Parsa, H. Bisadi, Mater. Des. 42, 478 (2012)

D. Feng, X.M. Zhang, S.D. Liu, Y.L. Deng, Mater. Sci. Eng. A 608, 63 (2014)

G. Wang, H. Peng, C. Zhang, S. Wang, and Y. Wen, Smart Mater. Struct. 25, 75013 (2016)

F. Chen, H. Wang, H. Zhu, H. Zhu, F. Ren, Z. Cui, J. Manuf. Process. 38, 223 (2019)

H.R. Rezaei Ashtiani, A.A. Shayanpoor, Mater. Today Commun. 28, 102652 (2021)

A.A.S. Mohammed, E.A. El-Danaf, A.K.A. Radwan, Mater. Sci. Eng. A 457, 373 (2007)

S.A. Sani, G.R. Ebrahimi, H. Vafaeenezhad, A.R. Kiani-Rashid, J. Magnes. Alloy. 6, 134 (2018)

N.R. Jaladurgam, A.K. Kanjarla, Mater. Sci. Eng. A 712, 240 (2018)

H. Matsumoto, V. Velay, J. Alloys Compd. 708, 404 (2017)

X.Y. Yang, M. Sanada, H. Miura, T. Sakai, Mater. Sci. Forum 488–489, 223 (2005)

N. Narita, J. Takamura, Philos. Mag. 29, 1001 (1974)

P. Zhou, J.Q. Zhou, Z.X. Ye, E. Jiang, W.B. Hu, H.L. Le, Strength Mater. 48, 69 (2016)

Y. Chen, L. Jin, J. Dong, Z. Zhang, F. Wang, Mater. Charact. 118, 363 (2016)

P. Nnamchi, A. Younes, S. González, Intermetallics 105, 61 (2019)

B. Wu, J. Li, L. Liu, X. Chen, J. Tan, J. Song, M. Rashad, F. Pan, Acta Metall. Sin. (Engl. Lett.) 34, 606 (2021)

P. Zhou, Q.X. Ma, Acta Metall. Sin. (Engl. Lett.) 30, 907 (2017)

C. Wu, S. Han, Acta Metall. Sin. (Engl. Lett.) 31, 963 (2018)

D.X. Wen, Y.C. Lin, Y. Zhou, Vacuum 141, 316 (2017)

M.S. Chen, Y.C. Lin, K.K. Li, Y. Zhou, Comput. Mater. Sci. 122, 150 (2016)

A.N. Behera, A. Chaudhuri, R. Kapoor, J.K. Chakravartty, S. Suwas, Mater. Des. 92, 750 (2016)

M.S. Chen, Y.C. Lin, X.S. Ma, Mater. Sci. Eng. A 556, 260 (2012)

A. Dehghan-Manshadi, P.D. Hodgson, Metall. Mater. Trans. A 39, 2830 (2008)

W.X. Wu, L. Jin, J. Dong, Z.Y. Zhang, W.J. Ding, Mater. Sci. Eng. A 556, 519 (2012)

S. Aliakbari Sani, G.R. Ebrahimi, A.R. Kiani Rashid, J. Magnes. Alloy. 4, 104 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Rezaei Ashtiani, H.R., Shayanpoor, A.A. Effect of Initial Grain Size on the Hot Deformation Behavior and Microstructural Evolution of Pure Copper. Acta Metall. Sin. (Engl. Lett.) 35, 662–678 (2022). https://doi.org/10.1007/s40195-021-01346-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01346-7