Abstract

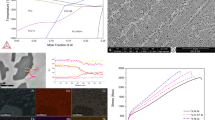

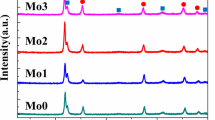

High-entropy alloys have attracted broad research interests due to their unique and intriguing mechanical properties. As a category of high-entropy alloys, eutectic high-entropy alloys combine the advantages of eutectic and high-entropy alloys, with excellent mechanical properties and casting properties. Some eutectic high-entropy alloys have been developed and shown exciting properties. In this paper, based on the physical metallurgy of eutectic high-entropy alloy, medium-entropy alloy Fe2NiCrNbx was designed. The as-cast alloy is composed of FCC and Laves phases, Nb element promotes the formation of primary Laves phase, and the hardness of the alloy increases with the increase in Nb element. Among the four alloys, the eutectic chemical composition at eutectic point is Fe2NiCrNb0.34; the alloy has a good strength and plastic balance. The ultimate comprehensive strength is 2267MPa, and the fracture strain is 30.8%. The experiment data and analyses identified the eutectic points and the excellent mechanical behavior. Moreover, the expensive Co element was replaced by Fe element. This cheap medium-entropy alloy has promising prospect in the consideration of the cost performance ratio.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

E.P. George, D. Raabe, R.O. Ritchie, Nat. Rev. Mater. 4, 515 (2019)

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

B.S. Murty, J.W. Yeh, S. Ranganathan, P.P. Bhattacharjee, High-Entropy Alloys (Elsevier, Amsterdam, 2019).

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Prog. Mater. Sci. 102, 296 (2019)

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan, T. Li, SCI REP-UK 4, 1 (2014)

Y. Lu, Y. Dong, H. Jiang, Z. Wang, Z. Cao, S. Guo, T. Wang, T. Li, P.K. Liaw, Scr. Mater. 187, 202 (2020)

Q. Wu, Z. Wang, X. Hu, T. Zheng, Z. Yang, F. He, J. Li, J. Wang, Acta Mater. 182, 278 (2020)

Q. Wu, Z. Wang, T. Zheng, D. Chen, Z. Yang, J. Li, J. Jung Kai, J. Wang, Mater. Lett. 253, 268 (2019)

F. He, Z. Wang, P. Cheng, Q. Wang, J. Li, Y. Dang, J. Wang, C.T. Liu, J. Alloy. Compd. 656, 284 (2016)

F. He, Z. Wang, X. Shang, C. Leng, J. Li, J. Wang, Mater. Des. 104, 259 (2016)

Y. Yu, F. He, Z. Qiao, Z. Wang, W. Liu, J. Yang, J. Alloy. Compd. 775, 1376 (2019)

J. Lu, Z. Wang, W. Wang, K. Zhou, F. He, Z. Wang, Acta Metall. Sin.-Engl. Lett. 33, 1111 (2020)

C. Ai, G. Wang, L. Liu, M. Guo, F. He, J. Zhou, Y. Chen, Z. Wang, B. Gan, Intermetallics 120, 106769 (2020)

J. Joseph, M. Imran, P.D. Hodgson, M.R. Barnett, D.M. Fabijanic, Manuf. Lett. 25, 16 (2020)

K. Zhou, J. Li, L. Wang, H. Yang, Z. Wang, J. Wang, Intermetallics 114, 106592 (2019)

Y. Yin, J. Zhang, Q. Tan, W. Zhuang, N. Mo, M. Bermingham, M.X. Zhang, Mater. Des. 162, 24 (2019)

Y. Dong, X. Gao, Y. Lu, T. Wang, T. Li, Mater. Lett. 169, 62 (2016)

T.T. Shun, L.Y. Chang, M.H. Shiu, Mater. Sci. Eng. A 556, 170 (2012)

T.T. Shun, L.Y. Chang, M.H. Shiu, Mater. Charact. 70, 63 (2012)

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, O.N. Senkov, J. Alloy. Compd. 591, 11 (2014)

J. Joseph, T. Jarvis, X. Wu, N. Stanford, P. Hodgson, D.M. Fabijanic, Mater. Sci. Eng. A 633, 184 (2015)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (Grant No. 2018YFB1105804), the Research Fund of the State Key Laboratory of Solidification Processing (NPU), China (Grant No. 2020-TS-06), and the BIAM YiCai Youth Foundation Program (Grant No. KJ53200134).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Song, J., Chai, Z., Zheng, J. et al. Design Fe-based Eutectic Medium-Entropy Alloys Fe2NiCrNbx. Acta Metall. Sin. (Engl. Lett.) 34, 1103–1108 (2021). https://doi.org/10.1007/s40195-021-01234-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01234-0