Abstract

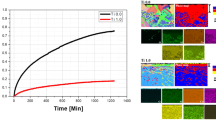

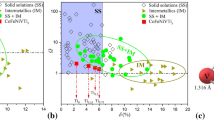

The microstructure evolution of AlCoCrFeNiTi0.5 alloy and AlCoCrFeNiCu alloy during heat treatment was systematically studied, to reveal the influence rules of chemical activity of adding element on the microstructure evolution of AlCoCrFeNi system. Owing to the negative mixing enthalpy with the constituent elements, Ti element was mainly dissolved in the Al–Ni-rich phases, and aggravated the lattice distortion of B2 phase. The structure variation of BCC phase by adding Ti inhibited the formation of FCC phase and enhanced the precipitation of σ phase during heat treatment. Owing to the positive mixing enthalpy with constituent elements, Cu element tended to be repelled to the ID region and formed metastable Cu-rich FCC1 phase which would transform into Cu–Al–Ni-rich FCC2 phase with increasing temperature. The addition of Cu inhibited the precipitation of σ phase during heat treatment. Adding Ti maintained the stable dendritic morphology, while adding Cu reduced the thermal stability of microstructure. Two dramatic morphology changes occurred at 1000 °C and 1100 °C in the AlCoCrFeNiCu alloy. The lattice distortion of phase in AlCoCrFeNiTi0.5 alloy was aggravated with increasing temperature up to 800 °C, then relaxed together with the dissolution of σ phase when temperature was above 900 °C. The variation in lattice distortion dominated the hardness of AlCoCrFeNiTi0.5 alloy. With increasing heating temperature, the increasing volume fraction of region with FCC structure due to the transformation between FCC phases, and the pronounced coarsening in microstructure due to the reduced thermal stability, resulted in the mainly decreasing trend in the hardness of AlCoCrFeNiCu alloy.

Similar content being viewed by others

References

Z. Li, S. Zhao, R.O. Ritchie, M.A. Meyers, Prog. Mater. Sci. 102, 296 (2019)

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, Y. Yang, Mater. Today 19, 349 (2016)

H. Zhang, B. Dou, H. Tang, Y. He, S. Guo, Mater. Des. 159, 224 (2018)

Y.L. Zhang, J.G. Li, X.G. Wang, Y.P. Lu, Y.Z. Zhou, X.F. Sun, J. Mater. Sci. Technol. 35, 902 (2019)

Y.P. Lu, H.F. Huang, X.Z. Gao, C.L. Ren, J. Gaob, H.Z. Zhang, S.J. Zheng, Q.Q. Jin, Y.H. Zhao, C.Y. Lu, T.M. Wang, T.J. Li, J. Mater. Sci. Technol. 35, 369 (2019)

C. Xiang, Z.M. Zhang, H.M. Fu, E.H. Han, J.Q. Wang, H.F. Zhang, G.D. Hu, Acta Metall. Sin. (Engl. Lett.) 32, 1053 (2019)

M.H. Tsai, J.W. Yeh, Mater. Res. Lett. 2, 107 (2014)

S. Chen, K.K. Tseng, Y. Tong, W. Li, C.W. Tsai, J.W. Yeh, P.K. Liaw, J. Alloy. Compd. 795, 19 (2019)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014)

T.T. Zuo, M.C. Gao, L.Z. Ouyang, X. Yang, Y.Q. Cheng, R. Feng, S.Y. Chen, P.K. Liaw, J.A. Hawk, Y. Zhang, Acta Mater. 130, 10 (2017)

Y.P. Lu, H. Jiang, S. Guo, T.M. Wang, Z.Q. Cao, T.J. Li, Intermetallics 91, 124 (2017)

L. Jiang, Y.P. Lu, M. Song, C. Lu, K. Sun, Z.Q. Cao, T.M. Wang, F. Gao, L.M. Wang, Scr. Mater. 165, 128 (2019)

D.X. Qiao, H. Jiang, W.N. Jiao, Y.P. Lu, Z.Q. Cao, T.J. Li, Acta Metall. Sin. (Engl. Lett.) 32, 925 (2019)

J.B. Cheng, D. Liu, X.B. Liang, B.S. Xu, Acta Metall. Sin. Engl. Lett. 27, 1031 (2014)

L.M. Du, L.W. Lan, S. Zhu, H.J. Yang, X.H. Shi, P.K. Liaw, J.W. Qiao, J. Mater. Sci. Technol. 35, 917 (2019)

Y. Yu, J. Wang, J.S. Li, J. Yang, H.C. Kou, W.M. Liu, J. Mater. Sci. Technol. 32, 470 (2016)

E.P. George, D. Raabe, R.O. Ritchie, Nat. Rev. Mater. 4, 515 (2019)

Z.M. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Nature 534, 227 (2016)

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014)

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, T.J. Li, Sci. Rep. 4, 5 (2014)

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Y. Zhao, Z. Cao, T. Li, Acta Mater. 124, 143 (2017)

X.Z. Gao, Y.P. Lu, B. Zhang, N.N. Liang, G.Z. Wu, G. Sha, J.Z. Liu, Y.H. Zhao, Acta Mater. 141, 59 (2017)

Y.P. Lu, X.X. Gao, Y. Dong, T.M. Wang, H.L. Chen, H.H. Mao, Y.H. Zhao, H. Jiang, Z.Q. Cao, T.J. Li, S. Guo, Nanoscale 10, 1912 (2018)

J. Hou, X. Shi, J. Qiao, Y. Zhang, P.K. Liaw, Y. Wu, Mater. Des. 180, 107910 (2019)

Y.J. Zhou, Y. Zhang, Y.L. Wang, G.L. Chen, Appl. Phys. Lett. 90, 18 (2007)

C.J. Tong, M.R. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, S.J. Lin, S.Y. Chang, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 36a, 1263 (2005)

Z.J.W.X.L. Shang, Q.F. Wu, J.C. Wang, J.J. Li, J.K. Yu, Acta Metall. Sin. (Engl. Lett.) 32, 41 (2019)

Y.T. Wang, J.B. Li, Y.C. Xin, X.H. Chen, M. Rashad, B. Liu, Y. Liu, Acta Metall. Sin. (Engl. Lett.) 32, 932 (2019)

T.D. Huang, H. Jiang, Y.P. Lu, T.M. Wang, T.J. Li, Appl. Phys. A-Mater. 125, 180 (2019)

A. Munitz, S. Salhov, G. Guttmann, N. Derimow, M. Nahmany, Mater. Sci. Eng. A 742, 1 (2019)

J.C. Rao, H.Y. Diao, V. Ocelik, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J.D. Poplawsky, Y. Zhou, P.K. Liaw, J.T.M. De Hosson, Acta Mater. 131, 206 (2017)

A. Verma, P. Tarate, A.C. Abhyankar, M.R. Mohape, D.S. Gowtam, V.P. Deshmukh, T. Shanmugasundaram, Scr. Mater. 161, 28 (2019)

Z.W. Yuan, W.B. Tian, F.G. Li, Q.Q. Fu, Y.B. Hu, X.G. Wang, J. Alloy. Compd. 806, 901 (2019)

Y. Yu, J. Wang, J. Yang, Z.H. Qiao, H.T. Duan, J.S. Li, J. Li, W.M. Liu, Tribol. Int. 131, 24 (2019)

Y. Yu, J. Wang, J.S. Li, H.C. Kou, W.M. Liu, Mater. Lett. 138, 78 (2015)

M. Chen, L. Lan, X.H. Shi, H.J. Yang, M. Zhang, J.W. Qiao, J. Alloy. Compd. 777, 180 (2019)

A. Munitz, S. Salhov, S. Hayun, N. Frage, J. Alloy. Compd. 683, 221 (2016)

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Acta Mater. 61, 4487 (2013)

A. Karati, M. Nagini, S. Ghosh, R. Shabadi, K.G. Pradeep, R.C. Mallik, B.S. Murty, U.V. Varadaraju, Sci. Rep. 9, 5331 (2019)

B.S. Murty, J.W. Yeh, S. Ranganathan, High Entropy Alloys, 1st edn. (Butterworth-Heinemann, Boston, 2014)

F.J. Wang, Y. Zhang, G.L. Chen, J. Alloy. Compd. 478, 321 (2009)

C. Lee, G. Song, M.C. Gao, R. Feng, P. Chen, J. Brechtl, Y. Chen, K. An, W. Guo, J.D. Poplawsky, S. Li, A.T. Samaei, W. Chen, A. Hu, H. Choo, P.K. Liaw, Acta Mater. 160, 158 (2018)

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, J. Banhart, Acta Mater. 59, 182 (2011)

A. Munitz, M.J. Kaufman, M. Nahmany, N. Derimow, R. Abbaschian, Mater. Sci. Eng. A 714, 146 (2018)

D.Y. Shih, C.A. Chang, J. Paraszczak, S. Nunes, J. Cataldo, J. Appl. Phys. 70, 3052 (1991)

A. Takeuchi, A. Inoue, Mater. Trans. 46, 2817 (2005)

Y.J. Zhou, Y. Zhang, T.N. Kim, G.L. Chen, Mater. Lett. 62, 2673 (2008)

J.M. Zhu, J.L. Meng, J.L. Liang, Rare Met 35, 385 (2016)

Y.J. Zhou, Y. Zhang, F.J. Wang, Y.L. Wang, G.L. Chen, J. Alloy. Compd. 466, 201 (2008)

A. Munitz, M.J. Kaufman, M. Nahmany, N. Derimow, R. Abbaschian, Metall. Mater. Trans. A 714, 146 (2018)

S. Liu, M.C. Gao, P.K. Liaw, Y. Zhang, J. Alloy Compd. 619, 610 (2015)

S.Q. Xia, M.C. Gao, Y. Zhang, Mater. Chem. Phys. 210, 213 (2018)

D. Li, Y. Zhang, Intermetallics 70, 24 (2016)

D. Li, M.C. Gao, J.A. Hawk, Y. Zhang, J. Alloy. Compd. 778, 23 (2019)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2018YFB2000100) and the National Natural Science Foundation of China (Nos. 51701227 and 51775532); one of the authors (Zhuhui Qiao) appreciates the support of the Taishan scholars Program of Shandong Province and the Outstanding Talents of Qingdao Innovations.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Yu, Y., Shi, P., Feng, K. et al. Effects of Ti and Cu on the Microstructure Evolution of AlCoCrFeNi High-Entropy Alloy During Heat Treatment. Acta Metall. Sin. (Engl. Lett.) 33, 1077–1090 (2020). https://doi.org/10.1007/s40195-020-01002-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01002-6