Abstract

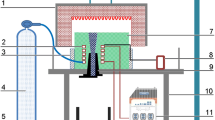

In the electromagnetic induction-controlled automated steel teeming (EICAST) technology of ladle, the height and location of the blocking layer are critical factors to determine the structure size and installation location of induction coil. And, they are also the key parameters affecting the successful implementation of this new technology. In this paper, the influence of the liquid steel temperature, the holding time and the alloy composition on the height and location of the blocking layer were studied by numerical simulation. The simulation results were verified by 40 t ladle industrial experiments. Moreover, the regulation approach of the blocking layer was determined, and the determination process of coil size and its installation location were also analyzed. The results show that the location of the blocking layer moves down with the increase in the liquid steel temperature and the holding time. The height of the blocking layer decreases with the increase in the liquid steel temperature; however, it increases with the increase in the holding time. The height and location of the blocking layer can be largely adjusted by changing the alloy composition of filling particles in the upper nozzle. When the liquid steel temperature is 1550 °C, the holding time is 180 min and the alloy composition is confirmed, the melting layer height is 120 mm, and the blocking layer height is 129 mm, which are beneficial to design and installation of induction coil. These results are very important for the industrial implementation of the EICAST technology.

Similar content being viewed by others

References

H.J. Lee, B.G. Thomas, S.H. Kim, Metall. Mater. Trans. B 47, 1453 (2016)

P.K. Singh, D. Mazumdar, Metall. Mater. Trans. B 49, 1945 (2018)

L.G. Yu, J.J. Wang, Shandong Metall. 33, 14 (2011)

D.J. Li, X.A. Liu, Q. Wang, J.C. He, J. Northeast. Univ. 33, 661 (2012)

D.J. Li, X.A. Liu, Q. Wang, R.H. Ouyang, H.S. Chai, J.C. He, J. Iron Steel Res. 24, 16 (2012)

Z.Y. Deng, B. Glaser, M.A. Bombeck, D. Sichen, Steel Res. Int. 87, 921 (2016)

A. Gao, Q. Wang, D.J. Li, B.G. Jin, K. Wang, J.C. He, Acta Metall. Sin. 46, 634 (2010). (in Chinese)

Z.Y. Deng, B. Glaser, M.A. Bombeck, D. Sichen, Steel Res. Int. 87, 484 (2016)

T.G. Wang, Z.H. Li, J. Hazard. Mater. B112, 63 (2004)

A. Gao, D.J. Li, Q. Wang, K. Wang, B.G. Jin, K. Marukawa, J.C. He, ISIJ Int. 50, 1770 (2009)

A. Gao, Q. Wang, B.G. Jin, J.C. He, J. Northeast. Univ. 31, 515 (2010)

D.J. Li, Q. Wang, X.A. Liu, A. Gao, X.B. Wang, J. Dong, K. Marukawa, J.C. He, J. Iron Steel Res. Int. 19, 766 (2012)

M. He, X.L. Li, Z.Q. Cao, S.L. Dong, T. Liu, Q. Wang, Vacuum 146, 130 (2017)

Q. Wang, D.J. Li, X.A. Liu, X.B. Wang, J. Dong, J.C. He, J. Iron Steel Res. Int. 22, 30 (2015)

Q. Wang, M. He, X.W. Zhu, X.L. Li, C.L. Wu, S.L. Dong, T. Liu, Acta Metall. Sin. 54, 228 (2018). (in Chinese)

X.A. Liu, Q. Wang, D.J. Li, G.L. Li, D.Q. Geng, A. Gao, J.C. He, ISIJ Int. 54, 482 (2014)

C.Y. Shi, J.C. He, Mater. Trans. 59, 39 (2018)

M. He, X.L. Li, X.A. Liu, X.W. Zhu, T. Liu, Q. Wang, Acta Metall. Sin. (Engl. Lett.) 32, 391 (2019)

W.H. Tong, F.M. Shen, H. Shibata, W.Z. Wang, Y.S. Yang, Y. Waseda, R. Takahashi, J.I. Yagi, Acta Metall. Sin. 38, 983 (2002). (in Chinese)

S.M. Yang, W.Q. Tao, Heat Transfer (Higher Education Press, Beijing, 2006), p. 555. (in Chinese)

Z.B. Fu, Induction Heating and Energy Conservation (China Machine Press, Beijing, 2008), p. 28. (in Chinese)

E. Abbasi, Q.S. Luo, D. Owens, Acta Metall. Sin. (Engl. Lett.) 32, 74 (2019)

W.B. Gao, D.P. Wang, F.J. Cheng, C.Y. Deng, W. Xu, Acta Metall. Sin. (Engl. Lett.) 28, 1097 (2015)

A. Gao, Q. Wang, D.J. Li, H.S. Chai, L.J. Zhao, J.C. He, Acta Metall. Sin. 47, 219 (2011). (in Chinese)

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant No. U1560207) and the Liaoning Innovative Research Team in University (Grant No. LT2017011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

He, M., Li, XL., Wang, QW. et al. Influence Factors Analysis of Fe–C Alloy Blocking Layer in the Electromagnetic Induction-Controlled Automated Steel Teeming Technology. Acta Metall. Sin. (Engl. Lett.) 33, 671–678 (2020). https://doi.org/10.1007/s40195-019-00957-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00957-5