Abstract

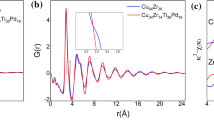

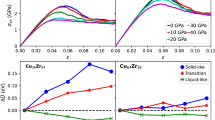

Electron diffraction was used to study the local atomic structure of Cu49Hf42Al9 metallic glasses (MGs). The amorphous nature of the MG was fully retained after the compression test. The partial radial distribution functions (PRDFs) of the MG structure obtained from the atomic model using reverse Monte Carlo and density functional theory optimization display that the peaks of the first nearest-neighbour distances for Cu–Cu, Hf–Cu and Hf–Hf atomic pairs were located at 2.56 Å, 2.78 Å and 3.23 Å, respectively. The wide distribution of PRDF for Hf–Hf atomic pair explained the high plasticity of the material.

Similar content being viewed by others

References

K. Yang, X.H. Fan, B. Li, Y.H. Li, X. Wang, X.X. Xu, Acta Metall. Sin. (Engl. Lett.) 31, 290 (2018)

Y. Dong, R. Wunderlich, J. Biskupek, Q.P. Cao, X.D. Wang, D.X. Zhang, J.Z. Jiang, H.J. Fecht, Scripta Mater. 137, 94 (2017)

J.J. Liu, R. Li, L.X. Fang, J. Wang, T. Zhang, Acta Metall. Sin. (Engl. Lett.) 29, 129 (2016)

F.F. Wu, S.S. Jiang, R.D. Zhao, Q. Zhou, G.A. Zhang, X.F. Wu, Mater. Sci. Eng., A 646, 272 (2015)

B. Zhang, Y.G. Chen, H.B. Guo, J. Alloys Compd. 582, 496 (2014)

E. Nagy, V. Rontó, J. Sólyom, A. Roósz, J. Phys: Conf. Ser. 144, 012035 (2009)

J.Y. Mo, H.S. Liu, Y. Zhang, M.Z. Wang, L. Zhang, B.Z. Liu, W.M. Yang, J. Non-Cryst, Solids 464, 1 (2017)

J.C. Zhang, C. Chen, Q.X. Pei, Q. Wan, W.X. Zhang, Z.D. Sha, Mater. Des. 77, 1 (2015)

X. Huang, Z. Ling, Y.J. Wang, L.H. Dai, Intermetallics 75, 36 (2016)

A. Inoue, W. Zhang, J. Saida, Mater. Trans. 45, 1153 (2004)

C.Y. Haein, J. Korean Phys. Soc. 60, 485 (2012)

E.S. Park, J.S. Kyeong, D.H. Kim, Scripta Mater. 57, 49 (2007)

P. Jia, H. Guo, Y. Li, J. Xu, E. Ma, Scripta Mater. 54, 2165 (2006)

G. Wang, S. Pauly, S. Gorantla, N. Mgttern, J. Eckert, J. Mater. Sci. Technol. 30, 609 (2014)

W.L. Ma, Y.L. Xu, B. Shi, J.G. Li, J. Mater. Sci. Technol. 33, 99 (2017)

T.M. Chung, S.R. Jian, P.J. Hsieh, Metals 6, 216 (2016)

Y.P. Jiang, K. Qiu, Mater. Des. 65, 410 (2015)

D.J.H. Cockayne, D.R. McKenzie, Acta Cryst. A 44, 870 (1988)

G.Q. Li, K.B. Borisenko, Y. Chen, D. Nguyen-Manh, E. Ma, D.J.H. Cockayne, Acta Mater. 57, 804 (2009)

X.H. Wang, A. Inoue, J.F. Zhao, F.L. Kong, S.L. Zhu, I. Kaban, M. Stoica, S. Oswald, C. Fan, E. Shalaan, F. Al-Marzouki, J. Eckert, F.X. Yin, Q. Li, J. Alloy. Compd. 739, 1104 (2018)

L. Tang, T.Q. Wen, N. Wang, Y. Sun, F. Zhang, Z.J. Yang, K.M. Ho, C.Z. Wang, Phys. Rev. Mater. 2, 03360 (2018)

D. Ma, A.D. Stoica, X.L. Wang, Nat. Mater. 8, 30 (2009)

G. Kresse, J. Hafner, Phys. Rev. B 48, 13115 (1993)

G. Kresse, J. Hafner, Phys. Rev. B 49, 14251 (1994)

F. Spaepen, Acta Metall. 25, 407 (1977)

J.C. Lee, K.W. Park, K.H. Kim, E. Fleury, B.J. Lee, M. Wakeda, Y. Shibutani, J. Mater. Res. 22, 3087 (2007)

Y.Q. Cheng, H.W. Sheng, E. Ma, Phys. Rev. B 78, 014207 (2008)

P.S. Steif, F. Spaepen, J.W. Hutchinson, Acta Metall. 30, 447 (1982)

T. Wada, A. Inoue, A.L. Greer, Appl. Phys. Lett. 86, 251907 (2005)

Acknowledgements

This work was supported by the National Science Fund for Excellent Young Scholars of China (No. 51422203), the National Natural Science Foundation of China (Nos. 51572091 and 51372001), the Natural Science Foundation of Guangdong Province, China (No. 2018A030313395), the China Postdoctoral Science Foundation (No. 2017M610522), the Science and Technology Program of Guangzhou, China (No. 201604046027), the Fundamental Research Funds for the Central Universities (No. 2017BQ035) and the fund of the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201716).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Li, K., Chou, YJ., Gao, FL. et al. Atomic Structure of Cu49Hf42Al9 Metallic Glass with High Glass-Forming Ability and Plasticity. Acta Metall. Sin. (Engl. Lett.) 32, 803–807 (2019). https://doi.org/10.1007/s40195-019-00907-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00907-1