Abstract

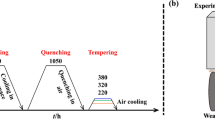

The microstructure and mechanical properties of NiCrMoV- and NiCrSi-alloyed medium-carbon steels were investigated after multiple tempering. After austenitising, the steels were hardened by oil quenching and subsequently double or triple tempered at temperatures from 250 to 500 °C. The samples were characterised using scanning electron microscopy and X-ray diffraction, while the mechanical properties were evaluated by Vickers hardness testing, V-notched Charpy impact testing and tensile testing. The results showed that the retained austenite was stable up to 400 °C and the applied multiple tempering below this temperature did not lead to a complete decomposition of retained austenite in both steels. It was also found that the microstructure, hardness and impact toughness varied mainly as a function of tempering temperature, regardless of the number of tempering stages. Moreover, the impact toughness of NiCrMoV steel was rather similar after single/triple tempering at different temperatures, while NiCrSi steel exhibited tempered martensite embrittlement after single/double tempering at 400 °C. The observed difference was mainly attributed to the effect of precipitation behaviour due to the effect of alloying additions in the studied steels.

Similar content being viewed by others

References

E. Abbasi, Q. Luo, D. Owens, Wear 398–399, 29 (2018)

Y. Wang, T. Lei, J. Liu, Wear 231, 12 (1999)

Y. Tomita, Int. Mater. Rev. 45, 23 (2000)

M. Assefpour-Dezfuly, A. Brownrigg, Metall. Trans. A 20, 1951 (1989)

G. Krauss, Steel Res. Int. 77, 1 (2017)

W.J. Nam, C.S. Lee, D.Y. Ban, Mater. Sci. Eng. A 289, 8 (2000)

G.R. Speich, W.C. Leslie, Metall. Trans. 3, 1043 (1972)

M. Jung, S.J. Lee, Y.K. Lee, Metall. Mater. Trans. A 40, 551 (2009)

F. Nazemi, J. Hamel-Akré, P. Bocher, J. Mater. Sci. 53, 6198 (2018)

D.A. Porter, K.E. Easterling, M. Sherif, Phase Transformations in Metals and Alloys, 3rd edn. (CRC Press, London, 2009)

L.C.F. Canale, R.A. Mesquita, G.E. Totten, Failure Analysis of Heat Treated Steel Components (ASM International, Ohio, 2008)

W.M. Garrison, U.S. Patent 2016/0237535 A1 (2016)

H.K.D.H. Bhadeshia, ISIJ Int. 56, 24 (2016)

A.J. Clarke, M.K. Miller, R.D. Field, D.R. Coughlin, P.J. Gibbs, K.D. Clarke, D.J. Alexander, K.A. Powers, P.A. Papin, G. Krauss, Acta Mater. 77, 17 (2014)

A.K. Sinha, B.P. Division, Defects and Distortion in Heat Treated Parts (ASM International, Russell, 1991)

X. Luo, G.E. Totten, J. ASTM Int. 8, 1 (2011)

MCh. Somani, D.A. Porter, L.P. Karjalainen, R.D.K. Misra, Metall. Mater. Trans. A 45, 1247 (2014)

D. Barbier, Adv. Eng. Mater. 14, 122 (2016)

E. Abbasi, Wear Behaviour of CBS, HISI and W1.2746 Steels (Sheffield Hallam University, Sheffield, 2017)

E. Abbasi, Q. Luo, D. Owens, Mater. Sci. Eng. A 725, 65 (2018)

C.L. Briant, Mater. Sci. Technol. 5, 138 (1989)

W.S. Lee, T.T. Su, J. Mater. Process. Technol. 87, 198 (1999)

E. Abbasi, W.M. Rainforth, Mater. Sci. Eng. A 651, 822 (2016)

B. Kim, E. Boucard, T. Sourmail, D.S. Martín, N. Gey, P.E.J. Rivera-Díaz-del-Castillo, Acta Mater. 68, 169 (2014)

Ph Lemble, A. Pineau, J.L. Castagne, Ph Dumoulin, Met. Sci. 13, 496 (1979)

R.M. Horn, R.O. Ritchie, Metall. Trans. A 9, 1039 (1978)

P. Verma, G.S. Rao, N.C.S. Srinivas, V. Singh, Mater. Sci. Eng. A 683, 172 (2017)

L.Å. Norström, Met. Sci. 10, 429 (1976)

J. Liu, H. Yu, J. Wang, T. Zhou, C. Song, Steel Res. Int. 86, 1082 (2015)

W.J. Nam, C.S. Lee, Mater. Sci. Technol. 14, 827 (1998)

S. Sackl, M. Zuber, H. Clemens, S. Primig, Metall. Mater. Trans. A 47, 3694 (2016)

Y. Xiao, W. Li, H.S. Zhao, X.W. Lu, X.J. Jin, Mater. Charact. 117, 84 (2016)

A. Zhang, G. Wang, S. Jia, U.S. Patent 2014/0124102 A1 (2014)

T. Sakuma, N. Watanabe, T. Nishizawa, Trans. Jpn. 21, 159 (1980)

Y. Tomita, T. Okawa, Mater. Sci. Eng. A 172, 145 (1993)

J. Krawczyk, P. Bala, J. Pacyna, J. Microsc. 237, 411 (2010)

Y. Tomita, K. Okabayashi, Metall. Trans. A 14, 2387 (1983)

M. Niikura, J.W. Morris, Metall. Trans. A 11, 1531 (1980)

E. Abbasi, W.M. Rainforth, Mater. Sci. Technol. 32, 1721 (2016)

J.G. Speer, E.D. Moor, K.O. Findley, D.K. Matlock, B.C.D. Cooman, D.V. Edmonds, Metall. Mater. Trans. A 42, 3591 (2011)

H. Bhadeshia, D.V. Edmonds, Met. Sci. 13, 325 (1979)

R. Wu, W. Li, S. Zhou, Y. Zhong, L. Wang, X. Jin, Metall. Mater. Trans. A 45, 1892 (2014)

D. Delagnes, F. Pettinari-Sturmel, M.H. Mathon, R. Danoix, F. Danoix, C. Bellot, P. Lamesle, A. Grellier, Acta Mater. 60, 5877 (2012)

Y. Zou, Y.B. Xu, Z.P. Hu, X.L. Gu, F. Peng, X.D. Tan, S.Q. Chen, D.T. Han, R. Misra, G.D. Wang, Mater. Sci. Eng. A 675, 153 (2016)

P. Michaud, D. Delagnes, P. Lamesle, M.H. Mathon, C. Levaillant, Acta Mater. 55, 4877 (2007)

W.R. Clough, R.M. Vennett, R.J. Hrubec, J. Basic Eng. 90, 21 (1968)

Acknowledgements

The authors would like to acknowledge the sponsorship provided by Innovate UK through the Knowledge Transfer Partnership Programme (KTP010269 Sheffield Hallam University and Tyzack Machine Knives Ltd.).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Abbasi, E., Luo, Q. & Owens, D. Microstructural Characteristics and Mechanical Properties of Low-Alloy, Medium-Carbon Steels After Multiple Tempering. Acta Metall. Sin. (Engl. Lett.) 32, 74–88 (2019). https://doi.org/10.1007/s40195-018-0805-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0805-6