Abstract

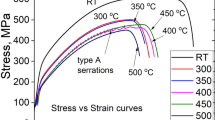

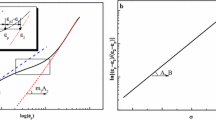

The strain rate sensitivity (SRS) and temperature sensitivity (TS) of 316L austenitic stainless steel were investigated by constant strain rate test (CSRT) and strain rate jump test (SRJT) under four temperatures (293, 373, 473 and 573 K) and four strain rates (5 × 10−4/s, 1 × 10−3/s, 5 × 10−3/s and 1 × 10−2/s). The results show that temperature sensitivity (TS) indexes at different strain rates are coincidence to be negative, related to temperature softening. On the contrary, SRS indexes change from positive to negative with the increase in temperature associated with dynamic strain aging (DSA). Moreover, based on the comparison between CSRT and SRJT, SRS and TS indexes obtained by two methods agree well. It proves that the SRJT can describe the SRS and TS phenomenon of 316L efficiently. Furthermore, the effects of temperature and strain rate on fracture mechanism were discussed. At last, an improved Johnson–Cook model was proposed to consider the temperature-dependent SRS behavior of 316L.

Similar content being viewed by others

References

Y.C. Lin, M. He, M. Zhou, D.X. Wen, J. Chen, J. Mater. Eng. Perform. 24, 3527 (2015)

Y. Yan, W.P. Deng, Z.F. Gao, Acta Metall. Sin. (Engl. Lett.) 29, 163 (2013)

J. Peng, C.Y. Zhou, Q. Dai, X.H. He, Mater. Des. 50, 968 (2013)

X.F. Li, J. Chen, L.Y. Ye, Acta Metall. Sin. (Engl. Lett.) 26, 657 (2013)

H.K. Yang, Y.Z. Tian, Z.J. Zhang, Z.F. Zhang, Mater. Sci. Eng. A 655, 251 (2016)

P. Verma, S. Rao, P. Chellapandi, Mater. Sci. Eng. A 621, 39 (2015)

X.D. Bian, F.P. Yuan, X.L. Wu, Mater. Sci. Eng. A 696, 220 (2017)

R. Kasadaa, S. Konishia, D. Hamaguchi, Fusion. Eng. Des. 109, 1507 (2016)

S.R. Bodner, Y. Partom, J. Appl. Mech. 42, 385 (1975)

H.S. Chen, W.X. Wang, H.H. Nie, Y.L. Li, Q.C. Wu, P. Zhang, Acta Metall. Sin. (Engl. Lett.) 28, 1214 (2015)

G.R. Johnson, W.H. Cook, Eng. Fract. Mech. 21, 31 (1985)

F.J. Zerilli, R.W. Armstrong, J. Appl. Phys. 61, 1816 (1987)

Z.B. Huang, M. Wan, H. Wu, J. Plast. Eng. 20, 89 (2013)

Y.C. Lin, X.M. Chen, Mater. Des. 32, 1733 (2011)

Y.C. Lin, Q.F. Li, Y.C. Xia, Mater. Sci. Eng. A 534, 654 (2012)

Y.C. Lin, X.M. Chen, G. Liu, Mater. Sci. Eng. A 527, 6980 (2010)

H.Y. Li, Y.H. Li, X.F. Wang, Mater. Des. 49, 493 (2013)

W.C. Jiang, J.M. Gong, S.T. Tu, Mater. Des. 31, 2157 (2010)

W.C. Jiang, B. Yang, X.W. Guan, Y. Luo, Acta Metall. Sin. (Engl. Lett.) 26, 241 (2013)

P. Ferro, A. Fabrizi, F. Bonollo, Acta Metall. Sin. (Engl. Lett.) 29, 859 (2016)

GB/T 228.1-2010

W.A. Backoken, I.R. Turner, D.H. Avery, J. Mater. Sci. 6, 1061 (1971)

K.W. Qian, J. Fuzhou. Univ. 16, 57 (1988)

E.I. Samuel, B.K. Choudhary, K.B.S. Rao, Scr. Mater. 46, 507 (2002)

Y.Q. Song, Z.P. Guan, Z. Li, Sci. China (Ser. E) 37, 1363 (2007)

Y.C. Lin, J. Deng, Y.Q. Jiang, Mater. Des. 55, 949 (2014)

B.K. Choudhary, Metall. Mater. Trans. A 44, 4979 (2013)

J. Yan, Q.L. Pan, A.D. Li, W.B. Song, Trans. Nonferrous Met. Soc. China 27, 638 (2017)

Y.H. Zhang, W. Zhang, J.L. Gao, Z.M. Yuan, W.G. Bu, Acta Metall. Sin. (Engl. Lett.) 30, 1040 (2017)

F. Ducobu, E. Rivière-Lorphèvre, E. Filippi, Int. J. Mech. Sci. 122, 143 (2017)

T. Mirzaiea, H. Mirzadeha, J.M. Cabrera, Mech. Mater. 94, 38 (2016)

D.Y. Li, Z.W. Zhu, S.N. Xiao, G.H. Zhang, Y.S. Lu, Mater. Sci. Eng. A 707, 459 (2017)

D.D. Chen, Y.C. Lin, Y. Zhou, M.S. Chen, D.X. Wen, J. Alloys Compd. 708, 938 (2017)

Y.C. Lin, Y.J. Liang, M.S. Chen, X.M. Chen, Appl. Phys. A 123, 68 (2017)

L. Gambirasio, E. Rizzi, Comput. Mater. Sci. 113, 231 (2016)

A. He, G.L. Xie, H.L. Zhang, X.T. Wang, Mater. Des. 52, 677 (2013)

Y.H. Zhao, J. Sun, J.F. Li, Y.Q. Yan, P. Wang, J. Alloys Compd. 723, 179 (2017)

X.Y. Wang, C.Z. Huang, B. Zou, H.L. Liu, H.T. Zhu, J. Wang, Mater. Sci. Eng. A 580, 385 (2013)

Acknowledgements

This project is financially supported by the National Natural Science Foundation of China (Grant No. 51505041) and the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 16KJB460002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Peng, J., Peng, J., Li, KS. et al. Temperature-Dependent SRS Behavior of 316L and Its Constitutive Model. Acta Metall. Sin. (Engl. Lett.) 31, 234–244 (2018). https://doi.org/10.1007/s40195-017-0697-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0697-x