Abstract

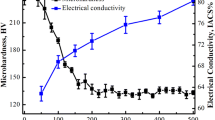

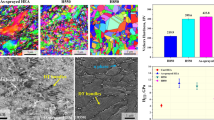

A new designed surface strengthening method, surface spinning strengthening (3S), was applied to achieve gradient microstructure in the surface layer of a Cu–11 at.%Al alloy. According to the level of grain refinement, the gradient microstructure can be divided into four zones, including nanoscale grain zone, ultra-fine grain zone, fine grain zone and coarse grain zone from the surface to the matrix. Meanwhile, a plenty of grain boundaries and twin boundaries were introduced to inhibit the dislocation motion in the surface layer during the plastic deformation process. Consequently, the hardened layer with a microhardness gradient and high residual compressive stress was produced on the samples, and the yield strength of the Cu–11 at.%Al alloy was effectively improved after 3S processing due to the strengthening effect caused by the gradient microstructure.

Similar content being viewed by others

References

E.P. Busso, S.D. Antolovich, Acta Mater. 107, 484 (2016)

R.O. Ritchie, Int. J. Fract. 100, 55 (1999)

A. Pineau, A. Amine Benzerga, T. Pardoen, Acta Mater. 107, 508 (2016)

N. Tsuji, S. Tanaka, T. Takasugi, Mater. Sci. Eng. A 488, 139 (2008)

H.W. Huang, Z.B. Wang, J. Lu, K. Lu, Acta Mater. 87, 150 (2015)

P.J. Withers, Rep. Prog. Phys. 70, 2211 (2007)

T.H. Fang, W.L. Li, N.R. Tao, K. Lu, Science 331, 1587 (2011)

T. Roland, D. Retraint, K. Lu, J. Lu, Scr. Mater. 54, 1949 (2006)

V. Llaneza, F.J. Belzunce, Appl. Surf. Sci. 356, 475 (2015)

H.B. Wang, G.L. Song, G.Y. Tang, J. Alloys Compd. 681, 146 (2016)

N. Tsuji, S. Tanaka, T. Takasugi, Surf. Coat. Technol. 203, 1400 (2009)

M.A.S. Torres, H.J.C. Voorwald, Int. J. Fatigue 24, 877 (2002)

C. Yuan, R.D. Fu, F.C. Zhang, X.Y. Zhang, F.C. Liu, Mater. Sci. Eng. A 565, 27 (2013)

Y.M. Lin, J. Lu, L.P. Wang, T. Xu, Q.J. Xue, Acta Mater. 54, 5599 (2006)

X.C. Liu, H.W. Zhang, K. Lu, Science 342, 337 (2013)

K.S. Kumar, H. Van Swygenhoven, S. Suresh, Acta Mater. 51, 5743 (2003)

R.Z. Valiev, Nat. Mater. 3, 511 (2004)

K. Lu, J. Lu, Mater. Sci. Eng. A 375, 38 (2004)

T. Roland, D. Retraint, K. Lu, J. Lu, Mater. Sci. Eng. A 445, 281 (2007)

J. Hirsch, K. Lucke, M. Hatherly, Acta Metall. 36, 2905 (1988)

J.W. Christian, S. Mahajan, Prog. Mater. Sci. 39, 1 (1995)

X.H. An, Q.Y. Lin, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, T.G. Langdon, Philos. Mag. 91, 3307 (2011)

R. Liu, Z.J. Zhang, Z.F. Zhang, Mater. Sci. Eng. A 666, 123 (2016)

X.H. An, Q.Y. Lin, S.D. Wu, Z.F. Zhang, R.B. Figueiredo, N. Gao, T.G. Langdon, Scr. Mater. 64, 954 (2011)

C. Ye, A. Telang, A.S. Gill, S. Suslov, Y. Idell, K. Zweiacker, J.M.K. Wiezorek, Z. Zhou, D. Qian, S.R. Mannava, V.K. Vasudevan, Mater. Sci. Eng. A 613, 274 (2014)

M.A. Meyers, A. Mishra, D.J. Benson, Prog. Mater Sci. 51, 427 (2006)

G.Z. Voyiadjis, B. Deliktas, Int. J. Plast. 25, 1997 (2009)

D. Kiener, A.M. Minor, Acta Mater. 59, 1328 (2011)

F. Macionczyk, W. Bruckner, J. Appl. Phys. 86, 4922 (1999)

A.H. Heuer, F. Ernst, H. Kahn, A. Avishai, G.M. Michal, D.J. Pitchure, R.E. Ricker, Scr. Mater. 56, 1067 (2007)

K. Lu, L. Lu, S. Suresh, Science 324, 349 (2009)

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, H. Gleiter, Nat. Mater. 1, 45 (2002)

J. Wang, X. Zhang, MRS Bull. 41, 274 (2016)

M.L. Kronberg, Acta Metall. 5, 507 (1957)

N. Tsuji, Y. Saito, H. Utsunomiya, S. Tanigawa, Scr. Mater. 40, 795 (1999)

Y.Z. Tian, J.J. Li, P. Zhang, S.D. Wu, Z.F. Zhang, M. Kawasaki, T.G. Langdon, Acta Mater. 60, 269 (2012)

L. Bardella, A. Panteghini, J. Mech. Phys. Solids 78, 467 (2015)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) under Grant Nos. 51331007 and 51501198.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Ren, CX., Wang, Q., Zhang, ZJ. et al. A Novel Method for Achieving Gradient Microstructure in a Cu–Al Alloy: Surface Spinning Strengthening (3S). Acta Metall. Sin. (Engl. Lett.) 30, 212–217 (2017). https://doi.org/10.1007/s40195-017-0551-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0551-1