Abstract

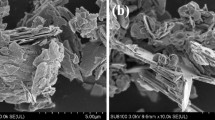

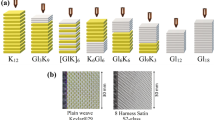

Tribological behavior of TiAl–multilayer graphene–Ag composites (TMACs) prepared by spark plasma sintering against a Si3N4 ball was investigated on a ball-on-disk high-temperature tribometer at different test temperatures and sliding speeds in this study. The test results showed that TMACs had the lower friction coefficient and less wear rate at 450 °C–0.25 m/s, which was attributed to the formation of the high-strength and intact tribofilms on worn surface. At 450 °C–0.25 m/s, during the sliding process, multilayer graphene (MLG) was ground out to form the high-strength skeletons on the worn surface of TMACs. Ag was migrated from the worn surface and combined with the MLG skeleton to form the high-strength and intact tribofilms. The high-strength and intact tribofilms were beneficial to lowering the friction coefficient for the lubricating effect of Ag and decreasing wear rate for the enhancing effect of MLG skeleton.

Similar content being viewed by others

References

J. Cheng, F. Li, Z.H. Qiao, S.Y. Zhu, J. Yang, W.M. Liu, Mater. Des. 84, 235 (2015)

A.E. Jiménez, M.D. Bermúdez, Tribol. Lett. 40, 246 (2010)

J. Cheng, J. Yang, J.Q. Ma, Q.L. Bi, X.H. Zhang, L.C. Fu, F. Li, S.G. Zhu, W.M. Liu, Tribol. Lett. 46(3), 241 (2012)

A.R. Rastkar, T. Bell, Wear 258, 1616 (2005)

X.F. Yang, J. Cheng, P.L. Song, S.R. Wang, L.Y. Yang, Y.J. Wang, K. Mao, Acta Metall. Sin. (Engl. Lett.) 26, 157 (2013)

W.T. Zhang, L.Z. Du, H. Lan, C.B. Huang, W.G. Zhang, Acta Metall. Sin. (Engl. Lett.) 26, 435 (2013)

J.H. Ouyang, S. Sasaki, T. Murakami, K. Umeda, Wear 258, 1444 (2005)

X.L. Shi, Z.S. Xu, M. Wang, W.Z. Zhai, J. Yao, S.Y. Song, A.Q. Din, Q.X. Zhang, Wear 303, 486–494 (2013)

O. Penkov, H.J. Kim, H.J. Kim, D.E. Kim, Int. J. Precis. Eng. Manuf. 15, 577 (2014)

H. Wang, G.T. Xie, Z.G. Zhu, Z. Ying, Y. Zeng, Compos. Part A Appl. S 67, 268 (2014)

Z.S. Xu, X.L. Shi, W.Z. Zhai, J. Yao, S.Y. Song, Q.X. Zhang, Carbon 67, 168 (2014)

J. Cheng, J. Yang, X.H. Zhang, Z. Hong, J.Q. Ma, F. Li, L.C. Fu, Q.L. Bi, J.S. Li, W.M. Liu, Intermetallics 31, 120 (2012)

M.A. Chowdhury, M.K. Khalil, D.M. Nuruzzaman, M.L. Rahaman, Int. J. Mech. Mechatron. Eng. 11, 53 (2011)

K. Yang, X.L. Shi, W.Z. Zhai, L. Chen, A. Zhang, Q.X. Zhang, RSC Adv. 5, 44618 (2015)

C.Q. Peng, B.Y. Huang, Y.H. He, Trans. Nonferrous Met. Soc. China 8, 11 (1998). (in Chinese)

ASTM E92-82, Standard test method for vickers hardness of metallic materials (ASTM International, 2003)

ASTM B962-08, Standard test methods for density of compacted or sintered powder metallurgy (PM) products using Archimedes’ principle (ASTM International, 2008)

G. Gedler, M. Antunes, V. Realinho, J.I. Velasco, Polym. Degrad. Stab. 97, 1297 (2012)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51275370); Self-determined and Innovative Research Funds of WUT (135204008); the Fundamental Research Funds for the Central Universities (2016-YB-017 and 2016-zy-014). Authors are grateful to M.J. Yang, S.L. Zhao and W.T. Zhu in Material Research and Test Center of WUT for their kind help with EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jia-Liang Zou and Kang Yang have contributed equally to this work.

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Zou, JL., Shi, XL., Shen, Q. et al. Tribological Behavior of TiAl–Multilayer Graphene–Ag Composites at Different Temperatures and Sliding Speeds. Acta Metall. Sin. (Engl. Lett.) 30, 193–200 (2017). https://doi.org/10.1007/s40195-017-0533-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0533-3