Abstract

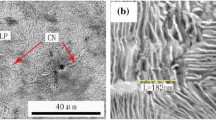

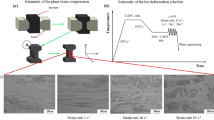

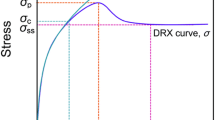

The compressive deformation behavior of 95CrMo hypereutectic steel was studied at temperatures ranging from 800 to 1050 °C and strain rates from 0.1 to 3 s−1 on a Gleeble-3500 thermo-simulation machine. The results showed that, with the decrease in deformation temperature and increase in strain rate, the fragmented retained austenite in finer and distributed more uniformly in the ferrite matrix as a result of the inhibited recovery. The recorded flow stress suggested that the stress level decreases with increasing temperature and decreasing strain rate. Based on the classical stress–dislocation relation, the constitutive equations of flow stress determined by work-hardening and softening mechanisms were established. A comparison between the experimental and calculated values confirmed the reliability of the model, and the predictability of the model was also quantified in terms of correlation coefficients and average absolute relative errors, which were found generally above 0.99 and below 2.50%, respectively. In the whole range of strain rate, the activation energy is 419.84 kJ/mol. By further identification based on Schöck’s model and Kocks–Argon–Ashby model, the rate-controlling mechanism is found to be dislocation cross-slip.

Similar content being viewed by others

References

F. Yin, L. Hua, H.J. Mao, X.H. Han, Mater. Des. 43, 393–401 (2014)

T. Yan, E.L. Yu, Y.Q. Zhao, Mater. Des. 50, 574–580 (2013)

K.P. Rao, Y.K.D.V. Prasad, E.B. Hawbolt, J. Mater. Process. Technol. 56, 908–917 (1996)

H.J. McQueen, S. Yue, N.D. Ryan, E. Fry, J. Mater. Process. Technol. 53, 293–310 (1995)

M.P. Phaniraj, A.K. Lahiri, J. Mater. Process. Technol. 141, 219–227 (2003)

Y.C. Lin, M.S. Chen, J. Zhong, Mech. Res. Commun. 35, 142–150 (2008)

F.A. Slooff, J. Zhou, J. Duszczyk, Scr. Mater. 57, 759–762 (2007)

Y.C. Lin, M.S. Chen, J. Zhong, Comput. Mater. Sci. 42, 470–477 (2008)

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, Mater. Sci. Eng. A 325, 112–125 (2002)

D.R. Lesuer, C.K. Syn, J.D. Whittenberger, Mater. Sci. Eng., A 317, 101–107 (2001)

Yu. Wei, B.S. Xie, B. Wang, S.X. Xu, J. Iron Steel Res. Int. 23, 910–916 (2016)

D.L. Hong, T.H. Gu, S.G. Xu, Drill Tool and Drill Steel (Metal. Industry Press, Beijing, 2000), pp. 121–134

Z.S. Wang, W. Yu, J.Z. Xiong, J. Iron Steel Res. 1, 22–25 (2009)

N.Q. Peng, G.B. Tang, J. Yao, J. Iron Steel Res. 20, 50–56 (2013)

J.G. Zhang, D.S. Sun, H.S. Shi, Mater. Sci. Eng. A 326, 20–25 (2002)

A. Saha, D.K. Mondal, K. Biswas, J. Maity, Mater. Sci. Eng. A 541, 204–215 (2012)

R. Ding, D. Tang, A.M. Zhao, Scr. Mater. 88, 21–24 (2014)

D.W. Suh, J.Y. Cho, K.H. Oh, ISIJ Int. 42, 564–566 (2002)

A. Yoshie, T. Fujita, M. Fujioka, ISIJ Int. 36, 467–473 (1996)

Y.Q. Song, Z.P. Guan, P.K. Ma, Acta Mater. Sin. 42, 673–680 (2006)

D. Samantaray, S. Mandal, A.K. Bhaduri, Mater. Des. 32, 2797–2802 (2011)

C. Zener, H. Hollomon, J. Appl. Phys. 15, 22–27 (1944)

S.A. Krishnan, C. Phaniraj, C. Ravishankar, Int. J. Pres. Ves. Pip. 88, 501–506 (2011)

F. Yin, L. Hua, H.J. Mao, Mater. Des. 55, 560–573 (2014)

C.X. Yue, L.W. Zhang, S.L. Liao, Mater. Sci. Eng. 339A, 560–573 (2014)

B.S. Xie, Q.W. Cai, W. Yu, Mater. Sci. Eng. 618A, 586–595 (2014)

O.D. Sherby, R.H. Klundt, A.K. Miller, Metall. Trans. 8A, 843–850 (1977)

G. Frommeyer, J.A. Jimenez, Metall. Mater. Trans. 36A, 295–300 (2005)

H.T. Zhao, G.Q. Liu, X. Lei, Mater. Sci. Eng. 559A, 262–267 (2013)

Y.V.R.K. Prasad, K.P. Rao, M. Gupta, Compos. Sci. Technol. 69, 1070–1076 (2009)

G.M. Luo, J.S. Wu, J.F. Fan, Mater. Sci. Eng. 379A, 302–307 (2004)

B. Walser, D.S. Oleg, Metall. Trans. 10A, 1461–1471 (1979)

D.J. Seol, Y.M. Won, T.J. Yeo, ISIJ Int. 39, 91–98 (1999)

A.S. Argon, M.C. Moffatt, Acta Metall. 29, 293–299 (1981)

A. Laasraoui, J.J. Jonas, Metal. Trans. 22A, 1545–1558 (1991)

Acknowledgments

This work was supported by the National Science & Technology Pillar Program during the Twelfth Five-year Plan Period (Grant Nos. 2012BAE03B01).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Xie, BS., Cai, QW., Yu, W. et al. Prediction for Flow Stress of 95CrMo Hollow Steel During Hot Compression. Acta Metall. Sin. (Engl. Lett.) 30, 250–260 (2017). https://doi.org/10.1007/s40195-016-0498-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0498-7