Abstract

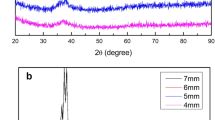

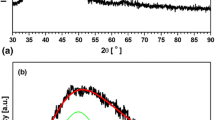

Unexpected facture without any room-temperature plasticity severely limits potential structural applications of bulk metallic glasses (BMGs), especially La-, Mg- and Fe-based ones. In this study, a simple free corrosion method was provided to improve the plasticity of a brittle (La, Ce)-based BMG by the introduction of high-density corrosion defects on the surface. The influences of immersing time in 0.1 mol/L H2SO4 aqueous solution on the surface morphology and mechanical properties of the BMG were evaluated. With increasing immersing time from 5 to 30 min, the degree of surface corrosion increased obviously, and the distribution of corrosion defects became more homogenous. In the samples, the yielding phenomenon and certain plasticity appeared up to 0.3% after the surface treatment. The yielding and plasticity can be attributed to easier nucleation of shear bands on the defect surface rather than on the glabrous surface. The results provided a novel method to improve the plasticity of BMGs.

Similar content being viewed by others

References

A. Inoue, Acta Mater. 48, 279 (2000)

M.F. Ashby, A.L. Greer, Scr. Mater. 54, 321 (2006)

W.L. Johnson, JOM 54, 40 (2002)

C.A. Schuh, T.C. Hufnagel, U. Ramamurty, Acta Mater. 55, 4067 (2007)

J. Wang, R. Li, N. Hua, T. Zhang, J. Mater. Res. 26, 2072 (2011)

O. Pelin, H. Aytekin, Acta Metall. Sin. (Engl. Lett.) 28, 733 (2015)

A.L. Greer, Y.Q. Cheng, E. Ma, Mater. Sci. Eng. R 74, 71 (2013)

L. Zhang, R. Li, T. Xu, H. Zhang, T. Zhang, Intermetallics 52, 92 (2014)

J.W. Qiao, M.M. Meng, Z.H. Wang, C.J. Huang, R. Li, Y.S. Wang, H.J. Yang, Y. Zhang, L.F. Li, AIP Adv. 4, 107 (2014)

T.G. Nieh, Y. Yang, J. Lu, C.T. Liu, Prog. Nat. Sci. 22, 355 (2012)

Y. Zhang, W.H. Wang, A.L. Greer, Nat. Mater. 5, 857 (2006)

J.P. Chu, J.E. Greene, J.S.C. Jang, J.C. Huang, Y. Shen, P.K. Liaw, Y. Yokoyama, A. Inoue, T.G. Nieh, Acta Mater. 60, 3226 (2012)

W. Chen, K.C. Chan, P. Yu, G. Wang, Mater. Sci. Eng. A 528, 2988 (2011)

S. Scudino, B. Jerliu, S. Pauly, K.B. Surreddi, U. Kuehn, J. Eckert, Scr. Mater. 65, 815 (2011)

B. Sarac, J. Schroers, Nat. Commun. 4, 2158 (2013)

B. Chen, Y. Li, M. Yi, R. Li, S. Pang, H. Wang, T. Zhang, Scr. Mater. 66, 1057 (2012)

G. Wu, R. Li, Z. Liu, B. Chen, Y. Li, Y. Cai, T. Zhang, Intermetallics 24, 50 (2012)

R. Li, F. Liu, S. Pang, C. Ma, T. Zhang, Mater. Trans., JIM 48, 1680 (2007)

T. Zhang, R. Li, S. Pang, J. Alloy. Compd. 483, 60 (2009)

R.T. DeHoff, in Q. Microscopy, ed. by F.N. Rhines, McGraw-Hill Series in Materials Science and Engineering (McGraw-Hill, New York, NY, 1968), p. 129

Z. Deng, C. Zhang, L. Liu, Intermetallics 52, 9 (2014)

X.K. Luo, R. Li, L. Huang, T. Zhang, Corros. Sci. 67, 100 (2013)

X.K. Luo, R. Li, Z.Q. Liu, L. Huang, M.J. Shi, T. Xu, T. Zhang, Mater. Lett. 76, 96 (2012)

Y. Jin, R. Li, T. Zhang, Intermetallics 67, 166 (2015)

R. Li, X.J. Liu, H. Wang, Y. Wu, X.M. Chu, Z.P. Lu, Corros. Sci. 84, 159 (2014)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51131002 and 51301196), the Fok Ying-Tong Education Foundation for Young Teachers in the Higher Education Institutions of China (No. 142008), the Fundamental Research Funds for the Central Universities (No. YWF-15-CLXY-002), and the Scientific Research Foundation for the Returned Overseas Chinese Scholars of State Education Ministry.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Liu, JJ., Li, R., Fang, LX. et al. Induced Plasticity of a Brittle (La, Ce)-Based Bulk Metallic Glass by Surface Corrosion. Acta Metall. Sin. (Engl. Lett.) 29, 129–133 (2016). https://doi.org/10.1007/s40195-016-0368-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0368-3