Abstract

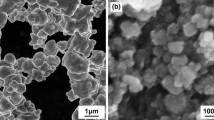

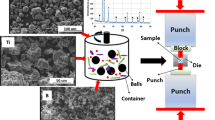

Silicon carbide nanoparticle-reinforced nickel-based composites (Ni–SiCNP), with a SiCNP content ranged from 1 to 3.5 wt%, were prepared using mechanical alloying and spark plasma sintering. In addition, unreinforced pure nickel samples were also prepared for comparative purposes. To characterize the microstructural properties of both the unreinforced pure nickel and the Ni–SiCNP composites transmission electron microscopy (TEM) was used, while their mechanical behavior was investigated using the Vickers pyramid method for hardness measurements and a universal tensile testing machine for tensile tests. TEM results showed an array of dislocation lines decorated in the sintered pure nickel sample, whereas, for the Ni–SiCNP composites, the presence of nano-dispersed SiCNP and twinning crystals was observed. These homogeneously distributed SiCNP were found located either within the matrix, between twins or on grain boundaries. For the Ni–SiCNP composites, coerced coarsening of the SiCNP assembly occurred with increasing SiCNP content. Furthermore, the grain sizes of the Ni–SiCNP composites were much finer than that of the unreinforced pure nickel, which was considered to be due to the composite ball milling process. In all cases, the Ni–SiCNP composites showed higher strengths and hardness values than the unreinforced pure nickel, likely due to a combination of dispersion strengthening (Orowan effects) and particle strengthening (Hall–Petch effects). For the Ni–SiCNP composites, the strength increased initially and then decreased as a function of SiCNP content, whereas their elongation percentages decreased linearly. Compared to all materials tested, the Ni–SiCNP composite containing 1.5% SiC was found more superior considering both their strength and plastic properties.

Similar content being viewed by others

References

I. Ibrahim, F. Mohamed, E. Lavernia, J. Mater. Sci. 26, 1137–1156 (1991)

F. Kiliç, H. Gül, S. Aslan, A. Alp, H. Akbulut, Colloids Surf. A 419, 53–60 (2013)

C. Dezauzier, N. Becourt, G. Arnaud, S. Contreras, J. Ponthenier, J. Camassel, J. Robert, J. Pascual, C. Jaussaud, Sens. Actuators A 46, 71–75 (1995)

B.M. Epelbaum, P.A. Gurzhiyants, S.V. Belenko, Mater. Lett. 34, 423–429 (1998)

D. Planson, M.-L. Locatelli, F. Lanois, J.-P. Chante, Mater. Sci. Eng. B 61, 497–501 (1999)

M. Bruzzi, F. Nava, S. Pini, S. Russo, Appl. Surf. Sci. 184, 425–430 (2001)

R. Wäsche, D. Klaffke, Wear 249, 220–228 (2001)

P. Wellmann, S. Bushevoy, R. Weingärtner, Mater. Sci. Eng. B 80, 352–356 (2001)

Y. Saberi, S. Zebarjad, G. Akbari, J. Alloys Compd. 484, 637–640 (2009)

B. Ghosh, S. Pradhan, J. Alloys Compd. 486, 480–485 (2009)

V. Izhevskyi, L. Genova, A. Bressiani, J. Bressiani, I. Int, J. Refract. Met. Hard. Mater. 19, 409–417 (2001)

K. Mussert, W.P. Vellinga, A. Bakker, S. Van Der Zwaag, J. Mater. Sci. 37, 789–794 (2002)

C. Carreño-Gallardo, I. Estrada-Guel, C. López-Meléndez, R. Martínez-Sánchez, J. Alloys Compd. 586, S68–S72 (2014)

L. Orlovskaja, N. Periene, M. Kurtinaitiene, S. Surviliene, Surf. Coat. Technol. 111, 234–239 (1999)

N.K. Shrestha, M. Masuko, T. Saji, Wear 254, 555–564 (2003)

B. El-Dasher, J. Farmer, J. Ferreira, M.S. de Caro, A. Rubenchik, A. Kimura, J. Nucl. Mater. 419, 15–23 (2011)

T. Yamasaki, Y. Zheng, Y. Ogino, M. Terasawa, T. Mitamura, T. Fukami, Mater. Sci. Eng. A 350, 168–172 (2003)

S. Qin, C. Chen, G. Zhang, W. Wang, Z. Wang, Mater. Sci. Eng. A 272, 363–370 (1999)

K. Zhang, I. Alexandrov, R. Valiev, K. Lu, J. Appl. Phys. 84, 1924–1927 (1998)

Q. Yang, A. Ghosh, Acta Mater. 54, 5159–5170 (2006)

H.W. Höppel, J. May, M. Göken, Adv. Eng. Mater. 6, 781–784 (2004)

E. Ma, Y. Wang, Q. Lu, M. Sui, L. Lu, K. Lu, Appl. Phys. Lett. 85, 4932–4934 (2004)

R. Valiev, I. Alexandrov, Y. Zhu, T. Lowe, J. Mater. Res. 17, 5–8 (2002)

H. Mughrabi, H. Höppel, M. Kautz, Scr. Mater. 51, 807–812 (2004)

V. Kaune, C. Müller, Mater. Sci. Eng. A 535, 1–5 (2012)

L.Q. Chen, Y.T. Yao, Acta Metall. Sin. (Engl. Lett.) 27, 762–774 (2014)

Y. Cui, L.D. Wang, B. Li, G.J. Cao, W.D. Fei, Acta Metall. Sin. (Engl. Lett.) 27, 937–943 (2014)

K. Maweja, M. Phasha, Y. Yamabe-Mitarai, J. Alloys Compd. 523, 167–175 (2012)

C.-L. Chen, Y.-M. Dong, Mater. Sci. Eng. A 528, 8374–8380 (2011)

Z.R. Hesabi, H. Hafizpour, A. Simchi, Mater. Sci. Eng. A 454, 89–98 (2007)

Y. Huang, Q.B. Ouyang, D. Zhang, J. Zhu, R.X. Li, H. Yu, Acta Metall. Sin. (Engl. Lett.) 27, 775–786 (2014)

M. Hussain, Y. Oku, A. Nakahira, K. Niihara, Mater. Lett. 26, 177–184 (1996)

Z.Y. Liu, B.L. Xiao, W.G. Wang, Z.Y. Ma, Acta Metall. Sin. (Engl. Lett.) 27, 901–908 (2014)

G.D. Hughes, S.D. Smith, C.S. Pande, H.R. Johnson, R.W. Armstrong, Scripta. Metall. 20, 93–97 (1986)

J.S. Benjamin, Metall. Trans. 1, 2943–2951 (1970)

C.P. Huang, C. Chen, C.Y. Liu, S.S. Lin, K.H. Chen, J. Mater. Res. 20, 2772–2779 (2005)

A.-F. Gourgues-Lorenzon, J.-M. Haudin, Matériaux pour l’ingénieur (Presses des mines, Paris, 2010), pp. 159–170

Acknowledgments

This research was supported by the China-Australia Joint Research Project (Grant No. 2014DFG60230), Knowledge Innovation program of Chinese Academy of Sciences and National Basic Research Program of China (Grant No. 2010CB832903 and 2010CB834503). The authors are grateful to “Shanghai Key Laboratory for High Temperature Materials and Precision Forming” for materials preparation by providing the SPS furnace.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Yang, C., Huang, HF., de los Reyes, M. et al. Microstructures and Tensile Properties of Ultrafine-Grained Ni–(1–3.5) wt% SiCNP Composites Prepared by a Powder Metallurgy Route. Acta Metall. Sin. (Engl. Lett.) 28, 809–816 (2015). https://doi.org/10.1007/s40195-015-0261-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-015-0261-5