Abstract

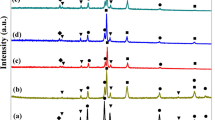

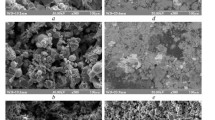

The (TiC–TiB2)/Cu composites with 50 vol% TiC–TiB2 ceramic particles were successfully fabricated by the combustion synthesis and hot press consolidation in a Cu–Ti–B4C–Cr system. The effects of the Cr content on the microstructures, hardness, compression properties, and abrasive wear behaviors of the composites were investigated. The final products consist of only Cu, TiC, and TiB2 phases, and the ceramic particles are distributed uniformly in these composites. The size of the ceramic particles decreases with Cr addition. As the Cr content increases, the yield strength, ultimate compression strength, microhardness, and abrasive wear resistance of the composites increase, and the fracture strain decreases.

Similar content being viewed by others

References

P.K. Deshpande, R.Y. Lin, Mater. Sci. Eng. A 418, 137 (2006)

S.C. Tjong, K.C. Lau, Mater. Lett. 43, 274 (2000)

S.C. Tjong, K.C. Lau, Mater. Sci. Eng. A 282, 183 (2000)

N. Zarrinfar, A.R. Kennedy, P.H. Shipway, Scr. Mater. 50, 949 (2004)

D.W. Lee, G.H. Ha, B.K. Kim, Scr. Mater. 44, 2137 (2001)

J.P. Tu, N.Y. Wang, Y.Z. Yang, W.X. Qi, F. Liu, X.B. Zhang, H.M. Lu, M.S. Liu, Mater. Lett. 52, 448 (2002)

F. Shehata, A. Fathy, M. Abdelhameed, S.F. Moustafa, Mater. Des. 30, 2756 (2009)

S.Y. Chang, S.J. Lin, Scr. Mater. 35, 225 (1996)

W. Zhang, N. Travitzky, P. Greil, J. Am. Ceram. Soc. 91, 3117 (2008)

F. Olevsky, P. Mogilevsky, E.Y. Gutmanas, I. Gotman, Metall. Mater. Trans. A 27, 2071 (1996)

D. Vallauri, F.A. Deorsola, Mater. Res. Bull. 44, 1528 (2009)

B.S. Du, S.R. Paital, N.B. Dahotre, Scr. Mater. 59, 1147 (2008)

J.J. Liu, Z.D. Liu, Mater. Lett. 64, 684 (2010)

F. Akhtara, S.J. Askaria, K.A. Shaha, X.L. Du, S.J. Guo, Mater. Charact. 60, 327 (2009)

L. Xia, B.B. Jia, J. Zeng, J.C. Xu, Mater. Charact. 60, 363 (2009)

S.R. Dong, J.P. Tu, X.B. Zhang, Mater. Sci. Eng. A 313, 83 (2001)

L. Zhang, X.B. He, X.H. Qu, B.H. Duan, X. Lu, M.L. Qin, Wear 265, 1848 (2008)

F. Akhtar, J. Alloys Compd. 459, 491 (2008)

H.Y. Wang, L. Huang, Q.C. Jiang, Mater. Sci. Eng. A 407, 98 (2005)

B.M. Chen, Q.L. Bi, J. Yang, Y.Q. Xia, J.C. Hao, Mater. Sci. Eng. A 491, 315 (2008)

Y.H. Liang, H.Y. Wang, Y.F. Yang, R.Y. Zhao, Q.C. Jiang, J. Alloys Compd. 462, 113 (2008)

Y. Choi, S.W. Rhee, J. Mater. Sci. 28, 6669 (1993)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51171071, 50971065 and No. 50531030), National Basic Research Program of China No. 2012CB619600), the Research Fund for the Doctoral Program of Higher Education of China (No. 20130061110037) and the Project 985–High Performance Materials of Jilin University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Qiu, F., Han, Y., Cheng, A. et al. Effect of Cr Content on the Compression Properties and Abrasive Wear Behavior of the High-Volume Fraction (TiC–TiB2)/Cu Composites. Acta Metall. Sin. (Engl. Lett.) 27, 951–956 (2014). https://doi.org/10.1007/s40195-014-0158-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-014-0158-8