Abstract

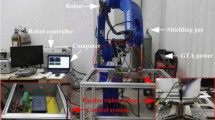

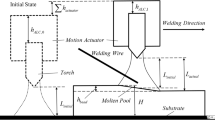

Wire and arc additive manufacturing (WAAM) shows a great application potential to manufacture large-size metal components rapidly. However, the research on WAAM to build structural parts on uneven substrates in some practical engineering applications is still a challenging issue. Controlling torch height and deposition height is the major barrier that limits the high level of automatic manufacturing of parts directly on uneven substrates. This study proposes a cooperative sensing and control strategy to achieve the process stability and deposition height control in robotic pulsed gas tungsten arc additive manufacturing (P-GTA AM) on an uneven substrate. The feedforward and feedback heights during the deposition process are monitored by a passive vision sensor. A feedforward controller and a feedback controller are designed to adjust the GTA torch height and the wire feed speed in real time, respectively. A thin-wall part was fabricated on a V-type substrate. The results demonstrate that the developed cooperative sensing and control strategy can ensure the process stability and realize the deposition height control in robotic P-GTA AM.

Similar content being viewed by others

References

Blakey-Milner B, Gradl P, Snedden G, Brooks M, Pitot J, Lopez E, Leary M, Berto F, du Plessis A (2021) Metal additive manufacturing in aerospace: a review. Mater Des 209:110008

Cai YH, Xiong J, Chen H, Zhang GJ (2023) A review of in-situ monitoring and process control system in metal-based laser additive manufacturing. J Manuf Syst 70:309–326

Oliveira JP, Santos TG, Miranda RM (2020) Revisiting fundamental welding concepts to improve additive manufacturing: from theory to practice. Prog Mater Sci 107:100590

Xiong J, Wen CF (2023) Arc plasma, droplet, and forming behaviors in bypass wire arc-directed energy deposition. Addit Manuf 70:103558

Han QL, Gao J, Han CL, Zhang GJ, Li YZ (2021) Experimental investigation on improving the deposition rate of gas metal arc-based additive manufacturing by auxiliary wire feeding method. Welding in the World 65:35–45

Spaniol E, Ungethum T, Trautmann M, Andrusch K, Hertel M, Fuessel U (2020) Development of a novel TIG hot-wire process for wire and arc additive manufacturing. Welding in the World 64(8):1329–1340

Duan XM, Li Q, Xie WR, Yang XD (2023) Wire arc metal additive manufacturing using pulsed arc plasma (PAP-WAAM) for effective heat management. J Mater Process Technol 311:117806

Martina F, Ding J, Williams S, Caballero A, Pardal G, Quintino L (2019) Tandem metal inert gas process for high productivity wire arc additive manufacturing in stainless steel. Addit Manuf 25:545–550

Liu GC, Xiong J (2020) External filler wire based GMA-AM process of 2219 aluminum alloy. Mater Manuf Processes 35(11):1268–1277

Giordano A, Diourte A, Bordreuil C, Bugarin F, Segonds AS (2022) Thermal scalar field for continuous three-dimensional toolpath strategy using wire arc additive manufacturing for free-form thin parts. Computer-Aided Design 151:103337

Farabi E, Klein T, Schnall M, Primig S (2023) Effects of high deposition rate during cold metal transfer additive manufacturing on microstructure and properties of Ti-6Al-4V. Addit Manuf 71:103592

Huang WJ, Wang Q, Ma NS, Kitano HC (2022) Distribution characteristics of residual stresses in typical wall and pipe components built by wire arc additive manufacturing. J Manuf Process 82:434–447

Le VT, Bui MC, Nguyen TD, Nguyen VA, Nguyen VC (2023) On the connection of the heat input to the forming quality in wire-and-arc additive manufacturing of stainless steels. Vacuum 209:111807

Chaurasia PK, Goecke SF, De A (2022) Real-time monitoring of temperature field, metal transfer and cooling rate during gas metal arc-directed energy deposition. Sci Technol Weld Joining 27(7):512–521

Li XL, Han QL, Zhang GJ (2021) Large-size sprocket repairing based on robotic GMAW additive manufacturing. Welding in the World 65:793–805

Yang DQ, Wang G, Zhang GJ (2017) Thermal analysis for single-pass multi-layer GMAW based additive manufacturing using infrared thermography. J Mater Process Technol 244:215–224

Choudhury SS, Marya SK, Amirthalingam M (2021) Improving arc stability during wire arc additive manufacturing of thin-walled titanium components. J Manuf Process 66:53–69

Tang F, Luo Y, Cai YH, Yang S, Zhang F, Peng Y (2022) Arc length identification based on arc acoustic signals in GTA-WAAM process. Int J Adv Manuf Technol 118(5–6):1553–1563

Qin J, Wang YP, Ding JL, Williams S (2022) Optimal droplet transfer mode maintenance for wire + arc additive manufacturing (WAAM) based on deep learning. J Intell Manuf 33:2179–2191

Veiga F, Suarez A, Aldalur E, Artaza T (2022) Wire arc additive manufacturing of invar parts: bead geometry and melt pool monitoring. Measurement 189:110452

Wang XL, Wang AM, Li YB (2020) An online surface height measurement method for GTAW-based additive manufacturing. Welding World 64:11–20

Yu YS, Xiong J, Chen Y, Zhao HH (2023) Process stability control of corner structures in robotic gas tungsten arc additive manufacturing via arc sensing. J Manuf Process 101:156–170

Scetinec A, Klobcar D, Bracun D (2021) In-process path replanning and online layer height control through deposition arc current for gas metal arc based additive manufacturing. J Manuf Process 64:1169–1179

Chabot A, Rauch M, Hascot JY (2021) Novel control model of contact-tip-to-work distance (CTWD) for sound monitoring of arc-based DED processes based on spectral analysis. Int J Adv Manuf Technol 116(11–12):3463–3472

Li YZ, Li XL, Zhang GJ, Horvath I, Han QL (2021) Interlayer closed-loop control of forming geometries for wire and arc additive manufacturing based on fuzzy-logic inference. J Manuf Process 63:35–47

Wang H, Jiang W, Ouyang J, Kovacevic R (2004) Rapid prototyping of 4043 Al-alloy parts by VP-GTAW. J Mater Process Technol 148(1):93–102

Xiong J, Zhang K (2022) Monitoring multiple geometrical dimensions in WAAM based on a multi-channel monocular visual sensor. Measurement 204:112097

Xu BH, Tan XD, Gu XZ, Ding DH, Deng YL, Chen Z, Xu J (2019) Shape-driven control of layer height in robotic wire and arc additive manufacturing. Rapid Prototyping Journal 25(10):1637–1646

Baxes GA (1994) Digital image processing: principles and applications. Wiley, New York

Davis LS (1975) A survey of edge detection techniques. Comput Graphics Image Process 4(3):248–270

Duda RO, Hart PE (1972) Use of the Hough transformation to detect lines and curves in pictures. Cacm 15(1):11–15

Zhang YY, Xiong J, Li DY, Zhang GJ (2023) Height control in GMA-AM using external wire as controlling variable. Mater Manuf Processes 38(8):971–979

Funding

This work was funded by National Natural Science Foundation of China, no. 51975491 and no. 62173280; Sichuan Science and Technology Program, no. 2023NSFSC1956; and the Fundamental Research Funds for the Central Universities, no. 2682023ZTPY023.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I—Additive Manufacturing, Surfacing, and Thermal Cutting.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, M., Xiong, J. Controlling torch height and deposition height in robotic wire and arc additive manufacturing on uneven substrate. Weld World 68, 765–779 (2024). https://doi.org/10.1007/s40194-023-01633-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01633-0