Abstract

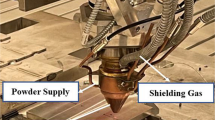

Nickel-based hardfacing alloys are widely used for the prevention of corrosion and wear losses in various industrial applications. They are prepared by various processes, and their properties are dependent on process parameters. In this study, the ERNiCr-B hardfacing alloy was deposited on AISI 304 stainless steel substrate using gas tungsten arc welding (GTAW) process using various processing parameters. Process parameters, namely, current, pre-heating temperature, and shielding gas flow rate of the GTAW process were optimized via Taguchi method. Confirmation test proved the validity of the optimization method. The optimum values of current, pre-heating temperature, and gas flow rate of the GTAW process for the deposition of ERNiCr-B hardfacing alloy on the 304 stainless steel substrate with respect to bead reinforcement were 130 A, 303.15 K, and 0.00015 m3/s, respectively. At optimum deposition condition, no evidence of defects such as microcracks, porosity, inclusions, etc. were observed in the hardfaced alloy. Among various parameters, the current had the most significant effect on dependent variables such as bead width, reinforcement height, hardness, and corrosion resistance of hardfaced deposit. Microstructural examination showed a typical dendritic structure with eutectic phases distributed in the inter-dendritic regions. Furthermore, the energy-dispersive X-ray spectroscopic (EDS) analysis showed the evidence of Fe dilution in ERNiCr-B deposit away from the substrate, which showed profound effect on hardness, microstructure, and corrosion rate.

Similar content being viewed by others

References

Balaguru S, Gupta M (2021) Hardfacing studies of Ni alloys : a critical review. J Mater Res Technol 10:1210–1242. https://doi.org/10.1016/j.jmrt.2020.12.026

Corchia M, Delogu P, Nenci F, Belmondo A, Corcoruto S, Stabielli W (1987) Microstructural aspects of wear-resistant stellite and colmonoy coatings by laser processing. Wear 119:137–152. https://doi.org/10.1016/0043-1648(87)90105-0

Chakraborty G, Rani R, Ramaseshan R, Davinci MA, Das CR, Mathews T et al (2021) High-Temperature tribological behavior of nickel-based hardfacing alloys. Tribol Trans 64:658–666. https://doi.org/10.1080/10402004.2021.1896059

Suthar F, Shah H, Chaudhury S (2021) A review on application of nickel base hardfacing alloys in sodium-cooled fast reactor. AIP Conf Proc 2395:030005. https://doi.org/10.1063/5.0068164

Mendez PF, Barnes N, Bell K, Borle SD, Gajapathi SS, Guest SD et al (2014) Welding processes for wear resistant overlays. J Manuf Processes 16:4–25. https://doi.org/10.1016/j.jmapro.2013.06.011

Bhaduri AK, Indira R, Albert SK, Rao BPS, Jain SC, Asokkumar S (2004) Selection of hardfacing material for components of the Indian Prototype Fast Breeder Reactor. J Nucl Mater 334:109–114. https://doi.org/10.1016/j.jnucmat.2004.05.005

Reinaldo PR, D’Oliveira ASCM (2013) NiCrSiB coatings deposited by plasma transferred arc on different steel substrates. J Mater Eng Proform 22:590–597. https://doi.org/10.1007/s11665-012-0271-7

Davis JR (2000) ASM specialty handbook: nickel, cobalt, and their alloys. ASM international, Ohio

Chakraborty G, Kumar N, Das CR, Albert SK, Bhaduri AK, Dash S et al (2014) Study on microstructure and wear properties of different nickel base hardfacing alloys deposited on austenitic stainless steel. Surf Coat Technol 244:180–188. https://doi.org/10.1016/j.surfcoat.2014.02.013

Gnanasekaran S, Padmanaban G, Balasubramanian V (2017) Effect of laser power on metallurgical, mechanical and tribological characteristics of hardfaced surfaces of nickel-based alloy. Lasers Manuf Mater Process 4:178–192. https://doi.org/10.1007/s40516-017-0045-z

Balaguru S, Murali V, Chellapandi P, Gupta M (2020) Effect of dilution on micro hardness of Ni–Cr–B–Si alloy hardfaced on austenitic stainless steel plate for sodium-cooled fast reactor applications. Nucl Eng Technol 52:589–596. https://doi.org/10.1016/j.net.2019.08.011

Chandran S, Vinayak SN, Subramanian V, Rangarajan S, Velmurugan S, Narasimhan SV et al (2011) Effect of substrate dilution on corrosion of colmonoy-6 weld overlays in nitric acid. Int J Nucl Energy Sci Technol 6:199–212. https://doi.org/10.1504/IJNEST.2011.043395

Siva K, Murugan N, Logesh R (2009) Optimization of weld bead geometry in plasma transferred arc hardfaced austenitic stainless steel plates using genetic algorithm. Int J Adv Manuf Technol 41:24–30. https://doi.org/10.1007/s00170-008-1451-3

Shanmugam R, Murugan N (2006) Effect of gas tungsten arc welding process variables on dilution and bead geometry of Stellite 6 hardfaced valve seat rings. Surf Eng 22:375–383. https://doi.org/10.1179/174329406X126726

Chakraborty G, Ramasubbu V, Albert SK et al (2012) Estimation of hardness in nickel-base hardafacing deposits on 316LN stainless steel by magnetic techniques. Weld World 56:101–110. https://doi.org/10.1007/BF03321152

Hsiao YF, Tarng YS, Huang WJ (2007) Optimization of plasma arc welding parameters by using the Taguchi method with the grey relational analysis. Mater Manuf Process 23:51–58. https://doi.org/10.1080/10426910701524527

Silva CC, de Miranda EC, Motta MF, de Miranda HC, Farias JP (2012) Dilution control of weld overlay superalloys using taguchi method. In: Proc ASME 31st Int Conf Ocean, Offshore Arctic Eng 6:289–299. https://doi.org/10.1115/OMAE2012-83971

Yousefieh M, Shamanian M, Saatchi A (2011) Optimization of experimental conditions of the pulsed current GTAW parameters for mechanical properties of SDSS UNS S32760 Welds Based on the Taguchi Design Method. J Mater Eng Perform 21:1978–1988. https://doi.org/10.1007/s11665-011-0105-z

Ravikumar SM, Vijian P (2017) Development of mathematical models for prediction of weld bead geometry of GTAW stainless steel. Appl Mech Mater 867:88–96. https://doi.org/10.4028/www.scientific.net/AMM.867.88

Chandrakanth B, Kumar SVA, Kumar SA, Sathish R (2013) Optimization and non-destructive test analysis of SS316L weldments using GTAW. Mater Res 17:190–195. https://doi.org/10.1590/S1516-14392013005000188

Bhattacharya A, Singla S (2016) Dissimilar GTAW between AISI 304 and AISI 4340 steel: multi-response optimization by analytic hierarchy process. In: Proc Mech Eng, Part E: J Process Mech Eng 231:824–835. https://doi.org/10.1177/0954408916641458

Zubairuddin M, Albert SK, Vasudevan M, Mahadevan S, Chaudhari V, Suri VK (2017) Numerical simulation of multi-pass GTA welding of grade 91 steel. J Manuf Process 27:87–97. https://doi.org/10.1016/j.jmapro.2017.04.031

Kumar P, Pai A (2014) An overview of welding aspects and challenges during manufacture of intermediate heat exchangers for 500MWe prototype fast breeder reactor. Procedia Eng 86:173–183. https://doi.org/10.1016/j.proeng.2014.11.026

ASTM standard E3–11 (2017) Standard guide for preparation of metallographic specimens. ASTM International, West Conshohocken, PA, USA. https://doi.org/10.1520/E0003-11R17. www.astm.org

ASTM standard E384–17 (2017) Standard test method for microhardness of materials. ASTM International, West Conshohocken, PA, USA. https://doi.org/10.1520/E0384-17. www.astm.org

Datta S, Bandyopadhyay A, Pal PK (2008) Grey-based Taguchi method for optimization of bead geometry in submerged arc bead-on-plate welding. Int J Adv Manuf Technol 39:1136–1143. https://doi.org/10.1007/s00170-007-1283-6

Branza T, Deschaux-Beaume F, Sierra G, Lours P (2009) Study and prevention of cracking during weld-repair of heat-resistant cast steels. J Mater Process Technol 2019:536–547. https://doi.org/10.1016/j.jmatprotec.2008.02.033

Gurumoorthy K, Kamaraj M, Rao KP, Venugopal S (2006) Microstructure and wear characteristics of nickel based hardfacing alloys deposited by plasma transferred arc welding. Mater Sci Technol 22:975–980. https://doi.org/10.1179/174328406X100734

Kesavan D, Kamaraj M (2010) The microstructure and high temperature wear performance of a nickel base hardfaced coating. Surf Coat Technol 204:4034–4043. https://doi.org/10.1016/j.surfcoat.2010.05.022

Guoqing C, Xuesong F, Yanhui W, Shan L, Wenlong Z (2013) Microstructure and wear properties of nickel-based surfacing deposited by plasma transferred arc welding. Surf Coat Technol 228:S276-282. https://doi.org/10.1016/j.surfcoat.2012.05.125

Ramasubbu V, Chakraborty G, Albert SK, Bhaduri AK (2011) Effect of dilution on GTAW Colmonoy 6 (AWS NiCr–C) hardface deposit made on 316LN stainless steel. Mater Sci Technol 27:573–580. https://doi.org/10.1179/026708309X12526555493431

Hemmati I, Ocelı́k V, De Hosson JTM (2012) Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater Lett 84:69–72. https://doi.org/10.1016/j.matlet.2012.06.054

Dupuy LM, Tadmor EB, Miller RE, Phillips R (2005) Finite-temperature quasicontinuum: molecular dynamics without all the atoms. Phys Rev Lett 95:060202–060211. https://doi.org/10.1103/PhysRevLett.95.060202

Stern M, Geary AL (1957) J Electrochem Soc 104:56–63. https://doi.org/10.1149/1.2428496

Siva K, Murugan N (2013) A study on the influence of PTAW process parameters on pitting corrosion resistance of nickel based overlays. Procedia Eng 64:1147–1156. https://doi.org/10.1016/j.proeng.2013.09.193

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I—Additive Manufacturing, Surfacing, and Thermal Cutting.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suthar, F.V., Shah, H.N., Parmar, R.N. et al. Optimization of GTAW process parameters for deposition of nickel-based hardfacing alloy using Taguchi method. Weld World 67, 1951–1966 (2023). https://doi.org/10.1007/s40194-023-01540-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01540-4