Abstract

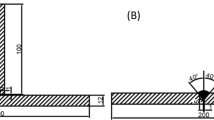

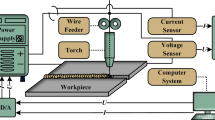

Wire-filled pulsed gas tungsten arc welding (GTAW-P) is usually used to join pipes in the horizontal position, in which uniform full penetration is required to guarantee a high weld quality. Based on the characteristic signals reflecting the penetration degree, the penetration control strategy of step welding is designed, and the dynamic modeling of backside molten pool width using the characteristic signals is conducted by back propagation (BP) neural network. The influence of step distance on the characteristic signals is explored. The weld is well shaped when the step distance is 3 mm. The backside weld width in the horizontal position can be controlled to be around the preset value with the control strategy of step welding and real-time feedback from the prediction of BP neural network. The control system is robust, which can work well under the fit-up condition of variable gap or variable heat dissipation in the horizontal welding of pipe.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The codes are not publicly available due to the commercial restriction.

References

Zeng ZT, Wang ZJ, Hu SS et al (2022) Dynamic molten pool behavior of pulsed gas tungsten arc welding with filler wire in horizontal position and its characterization based on arc voltage. J Manuf Process 75:1–12

Boughton P, Rider G. 1978 Feedback control of weld penetration. Welding Institute Conference Proceedings Advances in Welding Processes 203–215

Nagarajan S, Chen WH, Chin BA (1988) Welding penetration sensing and control. Infrared Technology XIV 972:268–272

Chen W, Chin BA (1990) Monitoring joint penetration using infrared sensing techniques. Weld J 69(5):181s–185s

Song JB, Hardt DE (1993) Closed-loop control of weld pool depth using a thermally based depth estimator. Weld J 72(10):471s–478s

Farson DR, Richardson R, Li X (1998) Infrared measurement of base metal temperature in gas tungsten arc welding. Weld J 77(9):217s–226s

Rokhlin SI, Guu AC (1990) Computerized radiographic sensing and control of an arc welding process. Weld J 69(3):83s–97s

Carlson NM, Johnson JA (1988) Ultrasonic sensing of weld pool penetration. Weld J 67(11):239s–246s

Liu X, Kannatry-Asibu E Jr (1990) Classification of AE signals for monitoring martensite formation from welding. Weld J 69(10):389s–394s

Richardson RW, Gutow DA, Anderson RA et al (1984) Coaxial welding pool viewing for processing monitoring and control. Weld J 63(3):43s–50s

Cook G E. 1983 Through-the-arc sensing for arc welding. Proceedings of Tenth Conference on Production Research and Technology (NSF ISBN O-89883–087–7) 141–151

Zhang YM, Kovacevic R, Wu L (1996) Dynamic analysis and identification of gas tungsten arc welding process for weld penetration control. Journal of Engineering for Industry 118(1):123–136

Zhang YM, Kovacevic R (1996) Adaptive control of full penetration gas tungsten arc welding. IEEE Trans Control Syst Technol 4(4):394–403

Liu YK, Zhang YM (2013) Control of 3D weld pool surface. Control Eng Pract 21(11):1469–1480

Zhang WJ, Zhang YM (2012) Modeling of human welder response to 3D weld pool surface: part I – principles. Weld J 91(11):310s–318s

Zhang WJ, Zhang YM (2012) Modeling of human welder response to 3D weld pool surface: part II – results and analysis. Weld J 91(12):329s–337s

Liu YK, Zhang YM, Kvidahl L (2014) Skilled human welder intelligence modeling and control: part I – modeling. Weld J 93(2):46s–52s

Liu YK, Zhang YM, Kvidahl L (2014) Skilled human welder intelligence modeling and control: part II – analysis and control applications. Weld J 93(5):162s–170s

Fan CJ, Lv FL, Chen SB (2009) Visual sensing and penetration control in aluminum alloy pulsed GTA welding. Int J Adv Manuf Technol 42(1–2):126–137

Chen J, Chen J, Feng Z et al (2019) Model predictive control of GTAW weld pool penetration. IEEE Robotics and Automation Letters 4(3):2762–2768

Madigan RB, Renwick RJ, Farson D et al (1986) Computer based control of full penetration GTA welds using pool oscillation sensing. Computer technology in welding (TWI) 165–174

Deam RT (1989) Weld pool frequency a new way to define a weld procedure. Recent trends in welding science and technology (ASM) 967–971

Xiao YH, den Ouden G (1990) A study of GTA weld pool oscillation. Weld J 69(8):289s–293s

Anedenroomer AJR, den Ouden G (1998) Weld pool oscillation as a tool for penetration sensing during pulsed GTA welding. Weld J 77(5):181s–187s

Wang QL, Yang CL, Geng Z (1993) Separately excited resonance phenomenon of the weld pool and its application. Weld J 72(9):455s–462s

Yang CL, He JS (1999) Welding penetration control with weld pool resonance in traveling pulse TIG welding. Transactions of the China Welding Institution 20(4):251–257 (In Chinese)

Wang ZJ, Zhang YM, Wu L (2010) Measurement and estimation of weld pool surface depth and weld penetration in pulsed gas metal arc welding. Weld J 89(6):117s–126s

Wang ZJ, Zhang YM, Wu L (2012) Adaptive interval model control of weld pool surface in pulsed gas metal arc welding. Automatica 48(1):233–238

Zou SY, Wang ZJ, Hu SS et al (2020) Control of weld penetration depth using relative fluctuation coefficient as feedback. J Intell Manuf 31:1203–1213

Cao Y, Wang ZJ, Hu SS et al (2021) Modeling of weld penetration control system in GMAW-P using NARMAX methods. J Manuf Process 65:512–524

Li XR, Shao Z, Zhang YM et al (2013) Monitoring and control of penetration in GTAW and pipe welding. Weld J 92(6):190s–196s

Li XR, Zhang YM (2014) Predictive control for manual plasma arc pipe welding. J Manuf Sci Eng 136(4):041017

Cheng YC, Xiao J, Chen SJ et al (2018) Intelligent penetration welding of thin-plate GTAW process based on arc voltage feedback. Trans China Weld Inst 39(12):1–4, 43 (In Chinese)

Zhang SQ, Hu SS, Wang ZJ (2016) Weld penetration sensing in pulsed gas tungsten arc welding based on arc voltage. J Mater Process Technol 229:520–527

Rider G (1986) Control of weld pool size and position. Rob Weld 217–226

Wang LR, Wang SA, Liu WH et al (2021) In-process visual monitoring of penetration state in nuclear steel pipe welding. Transactions on Intelligent Welding Manufacturing 193–200

Wang XC, Shi F, Yu L et al (2013) MATLAB neural network - analyses of 43 cases (Chinese edition). Beijing University of Aeronautics and Astronautics Press

Funding

This study is supported by the National Natural Science Foundation of China (Grant No.: 51505326) and Natural Science Foundation of Tianjin (Grant No.: 16JCQNJC04300).

Author information

Authors and Affiliations

Contributions

Zhijiang Wang: Conceptualization, methodology, formal analysis, resources, writing (review and editing), funding acquisition, project administration. Zitong Zeng: Methodology, software, formal analysis, investigation, data curation, visualization, writing—original draft. Shaojie Wu: Formal analysis, validation, writing—review and editing. Xinxin Shu: Formal analysis, validation. Chengfeng Wu: Methodology, software. Dongpo Wang: Supervision. Shengsun Hu: Writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors give their consent for the publication of identifiable details, which can include photograph(s) and/or videos and/or case history and/or details within the text to be published in Welding in the World.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Zeng, Z., Wu, S. et al. Weld penetration control of wire-filled pulsed gas tungsten arc welding of pipe in the horizontal position. Weld World 67, 1793–1807 (2023). https://doi.org/10.1007/s40194-023-01516-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-023-01516-4