Abstract

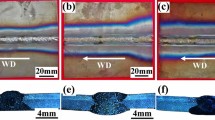

Research on the application of high-entropy alloys (HEAs) in the welding field has received extensive attention. The microstructures and mechanical properties of the weld metal with high-entropy features have been widely investigated. However, the corrosion and wear resistance have received little attention. In this work, the joining of TA1/Q345 bimetallic sheets was achieved using a multi-principal wire of Ni-Co-Al. The microstructures and properties of the weld metal surface were evaluated. It was found that the weld metal surface possessed five principal elements of Fe, Co, Ni, Al, and Ti, with the contents in the range of 5–40 at.%. Dendritic and interdendritic structures with the body-centered cubic (BCC) and Laves phases were observed in the weld metal. In a 3.5-wt.% NaCl solution, a greater impedance and better corrosion resistance were presented in the weld metal, compared to the base metal (BM)-TA1 and BM-Q345. Moreover, the weld metal exhibited the best wear resistance, with the wear loss being 0.36% of the BM-TA1. The results indicated that the weld metal of TA1/Q345 bimetallic sheet joints welded by using multi-principal wires of Ni-Co-Al had excellent corrosion and wear resistance.

Similar content being viewed by others

Data availability

Research data are not shared.

References

Li J, Zhou P, Shi H, Wang L (2021) Influence of filler metal on microstructure and properties of titanium/copper weld joint by GTAW weldments. Mater Sci Eng A 833:142508. https://doi.org/10.1016/j.msea.2021.142508

Hosseini SRE, Feng K, Nie P, Zhang K, Huang J, Chen Y, Shu D, Li Z, Guo B, Xue S (2018) Fracture surface characterization of laser welding processed Ti alloy to stainless steel joints. Weld World 62:947–960. https://doi.org/10.1007/s40194-018-0586-6

Zhang Y, Sun DQ, Gu XY, Li HM (2019) Characterization of laser-welded Ti alloy and stainless steel joint using Cu interlayer. J Mater Eng Perform 28:6092–6101. https://doi.org/10.1007/s11665-019-04319-1

Liu D, Wang W, Zha X, Jiao H, Zhao L, Han S (2021) Experimental investigation of butt welded Ti/steel bimetallic sheets by using multi-principal powders as a single filler metal. J Mater Res Technol 15:1499–1512. https://doi.org/10.1016/j.jmrt.2021.09.004

Jiang HT, Yan XQ, Liu JX, Duan XG (2014) Effect of heat treatment on microstructure and mechanical property of Ti–steel explosive-rolling clad plate. T Nonferr Metal Soc 24:697–704. https://doi.org/10.1016/S1003-6326(14)63113-7

Chai XY, Chen G, Chai F, Pan T, Yang ZG, Yang CF (2019) Hot roll bonding between commercially pure titanium and high-strength low-alloy steel using Fe interlayer. J Iron Steel Res Int 26:1126–1136. https://doi.org/10.1007/s42243-019-00322-x

Zhou Q, Liu R, Zhou Q, Ran C, Fan K, Xie J, Chen P (2021) Effect of microstructure on mechanical properties of titanium-steel explosive welding interface. Mater Sci Eng A 830:142260. https://doi.org/10.1016/j.msea.2021.142260

Wu T, Yang C (2021) Influence of pulse TIG welding thermal cycling on the microstructure and mechanical properties of explosively weld titanium/steel joint. Vacuum 197:110817. https://doi.org/10.1016/j.vacuum.2021.110817

Xu J, Yang M, Chen D, Ma H, Shen Z, Zhang B, Tian J (2021) Providing a new perspective for obtaining high-quality metal coatings: fabrication and properties studies of TA2 foil on Q235 steel by explosive welding. Arch Civ Mech Eng 21. https://doi.org/10.1007/s43452-021-00271-x

Chu Q, Tong X, Xu S, Zhang M, Yan F, Cheng P, Yan C (2020) The formation of intermetallics in Ti/steel dissimilar joints welded by Cu-Nb composite filler. J Alloys Compd 828:154389. https://doi.org/10.1016/j.jallcom.2020.154389

Zhang HB, Zhang LJ, Liu JZ, Ning J, Zhang JX, Na SJ, Zhu L (2020) Microstructures and performances of the butt joint of TA1/Q235B bimetallic sheet with addition of a Mo interlayer by using narrow gap laser welding with filler wire. J Mater Res Technol 9:10498–10510. https://doi.org/10.1016/j.jmrt.2020.07.054

Chu QL, Zhang M, Li JH, Jin Q, Fan QY, Xie WW, Luo H, Bi ZY (2015) Experimental investigation of explosion-welded CP-Ti/Q345 bimetallic sheet filled with Cu/V based flux-cored wire. Mater Des 67:606–614. https://doi.org/10.1016/j.matdes.2014.11.008

Chu Q, Zhang M, Li J, Fan Q, Xie W, Bi Z (2015) Joining of CP-Ti/Q345 sheets by Cu-based filler metal and effect on interface. J Mater Process Technol 225:67–76. https://doi.org/10.1016/j.jmatprotec.2015.05.017

Zhu ZY, Liu YL, Gou GQ, Gao W, Chen J (2021) Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci Rep 11:10020. https://doi.org/10.1038/s41598-021-89343-9

Gao Y, Zhang Y, Li J, Liu K, Xu Y, Zhou J (2021) Research on the performance of laser-MIG arc tandem welding of CP-Ti/304 stainless steel bimetallic sheets. Mater Lett 305:130805. https://doi.org/10.1016/j.matlet.2021.130805

Wang W, Wang M, Jie Z, Sun F, Huang D (2008) Research on the microstructure and wear resistance of titanium alloy structural members repaired by laser cladding. Opt Lasers Eng 46:810–816. https://doi.org/10.1016/j.optlaseng.2008.05.015

Vakili-Azghandi M, Roknian M, Szpunar JA, Mousavizade SM (2020) Surface modification of pure titanium via friction stir processing: Microstructure evolution and dry sliding wear performance. J Alloys Compd 816:152557. https://doi.org/10.1016/j.jallcom.2019.152557

Zhou L, Deng H, Chen L, Qiu W, Wei Y, Peng H, Hu Z, Lu D, Cui X, Tang J (2021) Morphological effects on the electrochemical dissolution behavior of forged and additive manufactured Ti-6Al-4V alloys in runway deicing fluid. Surf Coat Technol 414:127096. https://doi.org/10.1016/j.surfcoat.2021.127096

Tsai MH, Yeh JW (2014) High-entropy alloys: a critical review. Mater Res Lett 2:107–123. https://doi.org/10.1080/21663831.2014.912690

Fu Z, Jiang L, Wardini JL, MacDonald BE, Wen H, Xiong W, Zhang D, Zhou Y, Rupert TJ, Chen W, Lavernia EJ (2018) A high-entropy alloy with hierarchical nanoprecipitates and ultrahigh strength. Sci Adv 4:8712. https://doi.org/10.1126/sciadv.aat8712

Fu ZQ, Hoffman A, MacDonald BE, Jiang ZF, Chen WP, Arivu M, Wen HM, Lavernia EJ (2019) Atom probe tomography study of an Fe25Ni25Co25Ti15Al10 high-entropy alloy fabricated by powder metallurgy. Acta Mater 179:372–382. https://doi.org/10.1016/j.actamat.2019.08.047

Oliveira JP, Shamsolhodaei A, Shen J, Lopes JG, Gonçalves RM, De Brito FM, Piçarra L, Zeng Z, Schell N, Zhou N, Seop Kim H (2022) Improving the ductility in laser welded joints of CoCrFeMnNi high entropy alloy to 316 stainless steel. Mater Des 219:110717. https://doi.org/10.1016/j.matdes.2022.110717

Rhode M, Richter T, Schroepfer D, Manzoni AM, Schneider M, Eaplanche G (2022) Welding of high-entropy alloys and compositionally complex alloys-an overview. Weld World 65:1645–1659. https://doi.org/10.1007/s40194-021-01110-6

Nam H, Moon B, Park S, Kim N, Song S, Park N, Na Y, Kang N (2021) Gas tungsten arc weldability of stainless steel 304 using CoCrFeMnNi filler metals for cryogenic applications. Sci Technol Weld Join 27:33–42. https://doi.org/10.1080/13621718.2021.1996851

Liu D, Wang J, Xu M, Jiao H, Tang Y, Li D, Zhao L, Han S (2020) Evaluation of dissimilar metal joining of aluminum alloy to stainless steel using the filler metals with a high-entropy design. J Manuf Process 58:500–509. https://doi.org/10.1016/j.jmapro.2020.08.031

Wang C, Ma X, Zhang H, Zhang Y, Wang F, Song B (2022) Chloride corrosion property evolution of CrMnFeCoNi high-entropy alloy coating. Mater Sci Technol 1-7. https://doi.org/10.1080/02670836.2022.2080388

Wu MY, Chen K, Li XuZ, DY, (2020) Effect of Ti addition on the sliding wear behavior of AlCrFeCoNi high-entropy alloy. Wear 462:203493. https://doi.org/10.1016/j.wear.2020.203493

Lobel M, Lindner T, Mehner T, Lampke T (2018) Influence of titanium on microstructure, phase formation and wear behaviour of AlCoCrFeNiTix high-entropy alloy. Entropy 20:505–515. https://doi.org/10.3390/e20070505

Oliveira JP, Zeng Z, Braz AC, Fernandes FM, Miranda RM, Ramirez AJ, Omori T, Zhou N (2017) Dissimilar laser welding of superelastic NiTi and CuAlMn shape memory alloys. Mater Des 2128:166–175. https://doi.org/10.1016/j.matdes.2017.05.011

Cui P, Ma Y, Zhang L, Zhang M, Fan J, Dong W, Yu P, Li G (2018) Microstructure and mechanical behaviors of CoFeNiMnTixAl1-x high entropy alloys. Mater Sci Eng A 731:124–130. https://doi.org/10.1016/j.msea.2018.06.022

Yang X, Zhang Y (2012) Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater Chem Phys 132:233–238. https://doi.org/10.1016/j.matchemphys.2011.11.021

Guo S, Liu CT (2011) Phase stability in high entropy alloys: formation of solid-solution phase or amorphous phase. Prog Nat Sci 21:433–446. https://doi.org/10.1016/S1002-0071(12)60080-X

Dong Y, Yiping Lu, Jiang L, Wang T, Li T (2014) Effects of electro-negativity on the stability of topologically close-packed phase in high entropy alloys. Intermetallics 52:105–109. https://doi.org/10.1016/j.intermet.2014.04.001

Lu Y, Dong Y, Jiang L, Wang T, Li T, Zhang Y (2015) A criterion for topological close-packed phase formation in high entropy alloys. Entropy 17:2355–2366. https://doi.org/10.3390/e17042355

Nong ZS, Lei YN, Zhu JC (2018) Wear and oxidation resistances of AlCrFeNiTi-based high entropy alloys. Intermetallics 101:144–151. https://doi.org/10.1016/j.intermet.2018.07.017

Erdoğan A, Gök MS, Zeytin S (2019) Analysis of the high-temperature dry sliding behavior of CoCrFeNiTi0.5Alx high-entropy alloys. Friction 8:198–207. https://doi.org/10.1007/s40544-019-0278-2

Alikhani Chamgordani S, Miresmaeili R, Aliofkhazraei M (2018) Improvement in tribological behavior of commercial pure titanium (CP-Ti) by surface mechanical attrition treatment (SMAT). Tribol Int 119:744–752. https://doi.org/10.1016/j.triboint.2017.11.044

Liu D, Wang W, Li B, Jiao H, Tang Y, Hu Y, Zhao L (2022) A novel Ni-Co-Al multi-principal filler wire for inhibiting Fe-Ti intermetallic compounds in welding CP-Ti/Q345 bimetallic sheets. Sci Technol Weld Join. https://doi.org/10.1080/13621718.2022.2115667

Su G, Gao X (2017) Comparison of medium manganese steel and Q345 steel on corrosion behavior in a 3.5 wt % NaCl solution. Materials 10:938–948. https://doi.org/10.3390/ma10080938

Ma Y, Dong H, Li P, Yang J, Wu B, Hao X, Xia Y, Qi G (2022) A novel corrosion transformation process in aluminum alloy / galvanized steel welded joint. Corros Sci 194:109936. https://doi.org/10.1016/j.corsci.2021.109936

Dearnley DA, Dahm KL, Çimenoǧlu H (2004) The corrosion–wear behaviour of thermally oxidised CP-Ti and Ti–6Al–4V. Wear 256:469–479. https://doi.org/10.1016/S0043-1648(03)00557-X

Wang C, Li J, Wang T, Chai L, Deng C, Wang Y, Huang Y (2021) Microstructure and properties of pure titanium coating on Ti-6Al-4V alloy by laser cladding. Surf Coat Technol 416:127137. https://doi.org/10.1016/j.surfcoat.2021.127137

Wang Z, Zhao QZ (2018) Friction reduction of steel by laser-induced periodic surface nanostructures with atomic layer deposited TiO2 coating. Surf Coat Technol 344:269–275. https://doi.org/10.1016/j.surfcoat.2018.03.036

Zhang QY, Zhou Y, Li XX, Wang L Cui XH, Wang SQ (2016) Accelerated formation of tribo-oxide layer and its effect on sliding wear of a titanium alloy. Tribol Lett 63. https://doi.org/10.1007/s11249-016-0694-7

Jiang S, Lin Z, Xu H, Sun Y (2018) Studies on the microstructure and properties of AlxCoCrFeNiTi1-x high entropy alloys. J Alloys Compd 741:826–833. https://doi.org/10.1016/j.jallcom.2018.01.247

Han Z, Chen N, Lu S, Luan H, Peng R, Xu H, Shao Y, Peng Z, Yao K (2018) Structures and corrosion properties of the AlCrFeNiMo0.5Tix high entropy alloys. Mater Corros 69:641–647. https://doi.org/10.1002/maco.201709833

Lu SY, Yao KF, Chen YB, Wang MH, Chen N, Ge XY (2016) Effect of quenching and partitioning on the microstructure evolution and electrochemical properties of a martensitic stainless steel. Corros Sci 103:95–104. https://doi.org/10.1016/j.corsci.2015.11.010

Tabrizi AT, Aghajani H, Saghafian H, Laleh FF (2021) Correction of Archard equation for wear behavior of modified pure titanium. Tribol Int 155:106772. https://doi.org/10.1016/j.triboint.2020.106772

Erdogan A, Yener T, Zeytin S (2018) Fast production of high entropy alloys (CoCrFeNiAlxTiy) by electric current activated sintering system. Vacuum 155:64–72. https://doi.org/10.1016/j.vacuum.2018.05.027

Erdogan A, Doleker KM, Zeytin S (2019) Effect of Al and Ti on high-temperature oxidation behavior of CoCrFeNi-based high-entropy alloys. JOM 71:3499–3510. https://doi.org/10.1007/s11837-019-03679-2

Funding

This study was financially supported by the National Natural Science Foundation of China (51805171) and Graduate Innovation Foundation Project of Jiangxi Province (YC2021-S428).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Liu, D., Li, B. et al. Evaluation of surface corrosion and wear resistance in the weld metal by using multi-principal filler wires via high-entropy design. Weld World 66, 2389–2402 (2022). https://doi.org/10.1007/s40194-022-01380-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01380-8