Abstract

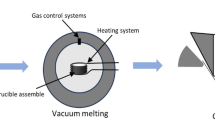

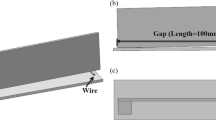

In this study, Cu-Sn-Ti active brazing alloys were prepared by vacuum induction melting. The microstructure and melting properties of as-cast Cu-Sn-Ti alloys were analyzed using scanning electron microscopy and differential scanning calorimetry. The optimal 87Cu-8Sn-5Ti paste was used for Al2O3/Cu brazing, and the sound joints were obtained in vacuum at 930 °C for 10 min. The joint microstructures were studied by means of SEM and EDS. The results show that there exist three zones in the brazing seam and the bonding area of the joint mainly consists of TiO, Cu3Ti3O and Cu-Ti compounds. The maximum value of the tensile strength of brazed joints reached 154 MPa.

Similar content being viewed by others

References

Chen HY, Ren XW, Guo W (2020) Effects of glass composition and joining parameters on microstructural evolution and mechanical properties of Al2O3/Cu joints brazed with Bi2O3-B2O3-ZnO glass. J Manuf Process 56:735–745

W. Tillmann, Jan Pfeiffer, L. Wojarski. Influencing factors on the reactive wetting of Cu-Sn-Ti and Ag-Cu-Ti alloys on silicon carbide-microstructural observations, effects and multivariate modeling. Advances in Science and Technology, 2014, 88:172–177.

Fu W, Song X G, Hu S P. Brazing copper and alumina metallized with Ti-containing Sn0.3Ag0.7Cu metal powder. Materials and Design, 2015, 87: 579–585.

Wu YC, Li H, Qu WQ et al (2020) Ultrasonic-assisted bonding of Al2O3 ceramic, Cu, and 5056 aluminum alloy with Sn-Zn-Sb solders. Welding in the World 64:247–256

Hafez KM, El-Sayed MH, Naka M (2005) Joining of alumina ceramics to metals. Sci Technol Weld Joining 10(2):125–130

Fu W, Hu SP, Song XG et al (2017) Effect of Ti content on the metallization layer and copper/alumina brazed joint. Ceram Int 43(16):13206–13213

Ning H L, Geng Z T, Ma J S, et al. Joining of sapphire and hot pressed Al2O3 using Ag70.5Cu27.5Ti2 brazing filler metal. Ceramics International, 2003, 29 (6): 689–694.

Zhao B, Yu T, Ding W (2017) Effects of pore structure and distribution on strength of porous Cu-Sn-Ti alumina composites. Chin J Aeronaut 30(6):2004–2015

Lin CC, Chen RB, Shiue RK (2001) A wettability study of Cu/Sn/Ti active braze alloys on alumina. J Mater Sci 36:2145–2150

Kozlova O, Braccini M, Voytovych R (2010) Devismes, Brazing copper to alumina using reactive CuAgTi alloys. Acta Mater 58:1252–1260

Majed Ali, Kevin M Knowles, Phillip M Mallinson. Microstructural evolution and characterisation of interfacial phases in Al2O3/Ag–Cu–Ti/Al2O3 braze joints. Acta Material, 2015, 96: 143–158.

Kozlova O, Braccini M, Voytovych R (2010) Brazing copper to alumina using reactive CuAgTi alloys. Acta Material 58:1252–1260

Wu SB, Xiong HP, Chen B et al (2017) Joining of SiO2f/SiO2 composite to Al2O3 ceramic using AgCuTi brazing filler metal. Welding in the World 61:181–186

Mukhopadhyay P, Ghosh A (2019) High vacuum brazing of synthetic diamond grits with steel using micro/nano Al2O3 reinforced Ag-Cu-Ti alloy. J Mater Process Technol 266:198–207

Wang Y, Jin C, Yang ZW et al (2019) Effects of Cu interlayers on the microstructure and mechanical properties of Al2O3/AgCuTi/Kovar brazed joints. Int J Appl Ceram Technol 16:896–906

Zhao Y, Wang Y, Yang ZW et al (2019) Relief of residual stress in Al2O3/Nb joints brazed with Ag-Cu-Ti/Cu/Ag-Cu-Ti composite interlayer. Archives of Civil and Mechanical Engineering 19(1):1–10

Niu GB, Wang DP, Yang ZW et al (2017) Microstructure and mechanical properties of Al2O3/TiAl joints brazed with B powders reinforced Ag-Cu-Ti based composite fillers. Ceram Int 43(1):439–450

Yang ZW, Lin JM, Wang Y (2017) Characterization of microstructure and mechanical properties of Al2O3/TiAl joints vacuum-brazed with Ag-Cu-Ti+W composite filler. Vacuum 143:294–302

Jin B X, H X, Zou M Q, et al. Joining of Al2O3 ceramic to Cu using refractory metal foil. Ceramics International, 2022, 48 (3):3455–3463.

Kozlova O, Braccini M, Voytovych R et al (2010) Brazing copper to alumina using reactive CuAgTi alloys. Acta Mater 58:1252–1260

Hsieh YC, Lin ST (2008) Microstructural development of Cu-Sn-Ti alloys on graphite. J Alloy Compd 466:126–132

Fan YG, Fan JX, Wang C (2019) Brazing temperature-dependent interfacial reaction layer features between CBN and Cu-Sn-Ti active filler metal. J Mater Sci Technol 35(10):2163–2168

Wang Y, Qiu XM, Sun DQ (2011) Influence of Ti on microstructure and strength of C-BN/Cu-Ni-Sn-Ti composites. Int J Refract Metal Hard Mater 29:293–297

Liu S, Xiao B, Xiao H (2016) Characteristics of Al2O3/diamond/c-BN/SiC grain steel brazing joints using Cu-Sn-Ti active filler powder alloys. Surf Coat Technol 286:376–382

Sealing tensile strength test method for ceramic-metal, SJ/T 3326–2016, (China Standard Press).

Test Method of Wettability for Brazing Filler Metals , GB/T 11364–2008, (China Standard Press).

Moser, W. Ga ̧sior, J. Pstrus. ́Surface tension of liquid Ag-Sn alloys:

experiment versus modeling (2001) Journal of Phase Equilibria 22(3):254–258

Du Q B. Research on the behavior of In/Al/RE in CuSnTi active brazing filler metal. China Academy of Machinery Science and Technology, 2017.

Yi J, Zhang Y, Wang X et al (2016) Characterization of Al/Ti nano multilayer as a jointing material at the interface between Cu and Al2O3. Mater Trans 57(9):1494–1497

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, L., Wang, W., Huang, X. et al. Joining of Al2O3 to Cu with Cu-Sn-Ti active brazing filler alloy. Weld World 66, 1471–1479 (2022). https://doi.org/10.1007/s40194-022-01305-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01305-5