Abstract

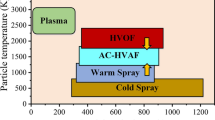

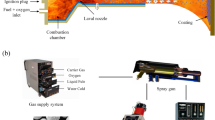

The flame flow characteristics, combustion mechanism, and particle flight behavior of warm spraying have been studied to broaden the warm spraying application of phase-sensitive materials. We used computational fluid dynamics (CFD) to study the flight behavior of titanium alloy powder particles during warm spraying. The renormalization group (RNG) and the k-ε turbulence model were used to solve the gas phase model. The single-step chemical reaction model and the eddy dissipation model (EDM) were combined to simulate the spray combustion reaction. On this basis, the discrete phase (DPM) model of titanium particles in the flame was carried out by the Lagrangian method to determine the particle flight behavior. In the study, the static pressure and flame temperature of the combustion products in the combustion chamber reached 0.39 MPa and 3305 K, respectively. The flame flows through the Laval nozzle with the convergence and divergence by 1668 m/s. It is an effective way to control the particle temperature without undesirable changes in particle velocity by adjusting the mass flow rate of the cooling gas. Warm spraying is more suitable for phase-sensitive and complex spraying materials. The flight behavior of small particles will be easily affected by the flame flow, while the large particles maintain their momentum and energy. The particle diameter and injection velocity were limited to no more than 55 μm and 20 m/s, which can effectively prevent particles from adhering and blocking the inner wall of the barrel.

Similar content being viewed by others

References

Kim KH, Watanabe M, Kuroda S (2009) Jetting-out phenomenon associated with bonding of warm-sprayed titanium particles onto steel substrate. J Therm Spray Techn 18(4):490–499. https://doi.org/10.1007/s11666-009-9379-1

Bai-lin ZHA, Xu-dong JIA, Jin-jin WANG et al (2020) Analysis on deposition behaviour of WC-12Co particles sprayed by HVOF. Surf Technol 49(11):101–110. https://doi.org/10.16490/j.cnki.issn.1001-3660.2020.11.012

Liu F, Li Z, Fang M et al (2021) Numerical analysis of the activated combustion high-velocity air-fuel spraying process: a three-dimensional simulation with improved gas mixing and combustion mode. Materials 14(3):657. https://doi.org/10.3390/ma14030657

Jafari H, Emami S, Mahmoudi Y (2017) Numerical investigation of dual-stage high velocity oxy-fuel(HVOF) thermal spray process: a study on nozzle geometrical parameters. Appl Therm Eng 111(Complete):745–758. https://doi.org/10.1016/j.applthermaleng.2016.09.145

Luo X T, Chidambaram-Seshadri R, Yang GJ (2019) Micro-nanostructured cermet coatings. In: Advanced nanomaterials and coatings by thermal spray. Elsevier, pp 61–117. https://doi.org/10.1016/B978-0-12-813870-0.00004-8

A.N. A, B.J. A, D.P. B et al (2021) Particle temperature effect in cold spray: a study of soft particle deposition on hard substrate. Surf Coat Tech 406:126735. https://doi.org/10.1016/j.surfcoat.2020.126735

Kuroda S, Kawakita J, Watanabe M et al (2015) Current status and future prospects of warm spray technology. In: Future development of thermal spray coatings. Woodhead Publishing, pp 163–206. https://doi.org/10.1007/s11666-011-9648-7

Myalska H, Szymański K, Moskal G (2015) Microstructure and properties Of WC-Co HVAF coatings obtained from standard, superfine and modified by sub-micrometric carbide powders. Arch Metall Mater 60(2):759–766. https://doi.org/10.1515/amm-2015-0203

Tabbara H, Gu S (2009) Computational simulation of liquid-fuelled HVOF thermal spraying. Surf Coat Tech 204(5):676–684. https://doi.org/10.1016/j.surfcoat.2009.09.005

Yuan X, Wang H, Hou G et al (2006) Numerical modeling of a low temperature high velocity air fuel spraying process with injection of liquid and metal particles. J Therm Spray Techn 15(3):413–421. https://doi.org/10.1361/105996306X124428

Wang X, Song Q, Yu Z (2016) Numerical investigation of combustion and flow dynamics in a high velocity oxygen-fuel thermal spray gun. J Therm Spray Techn 25(3):441–450. https://doi.org/10.1007/s11666-015-0362-8

Tabbara H, Gu S, Mccartney DG et al (2011) Computational modelling of titanium particles in warm spray. Comput Fluids 44(1):358–368. https://doi.org/10.1016/j.compfluid.2011.01.034

Jadidi M, Moghtaderenjad S, Dolatabadi A (2016) Numerical modeling of suspension HVOF spray. J Therm Spray Techn 25(3):451–464. https://doi.org/10.1007/s11666-015-0364-6

He XB, Wu NC, Zhang SD et al (2020) Effect of spraying distance on porosity of Fe based amorphous coatings. Mater Sci Technol 28(01):31–38. https://doi.org/10.11951/j.issn.1005-0299.2018

Khan MN, Shamim T (2014) Investigation of a dual-stage high velocity oxygen fuel thermal spray system. Appl Energy 130(oct.1):853–862. https://doi.org/10.1016/j.apenergy.2014.03.075

Gao X, Li C, Zhang D et al (2020) Numerical analysis of the activated combustion high-velocity air-fuel (AC-HVAF) thermal spray process: a survey on the parameters of operation and nozzle geometry. Surf Coat Technol. https://doi.org/10.1016/j.surfcoat.2020.126588

Gao X, Li C, Xu Y et al (2021) Effects of fuel types and process parameters on the performance of an activated combustion high velocity air-fuel (AC-HVAF) thermal spray system. J Therm Spray Technol:1–16. https://doi.org/10.1007/s11666-021-01250-7

Li C, Gao X, Zhang D et al (2021) Numerical Investigation on the flame characteristics and particle behaviors in a HVOF spray process using kerosene as fuel. J Therm Spray Technol 30(5–6). https://doi.org/10.1007/s11666-021-01165-3

Li M, Shi D, Christofides PD (2005) Modeling and control of HVOF thermal spray processing of WC-Co coatings. Powder Technol 156(2–3):177-194. https://doi.org/10.1016/j.powtec.2005.04.011

Gu S, Kamnis S (2009) Numerical modelling of in-flight particle dynamics of non-spherical powder. Surf Coat Tech 203(22):3485–3490. https://doi.org/10.1016/j.surfcoat.2009.05.024

Cha BL, Jia XD, Wang JJ et al (2020) Effect of substrate surface roughness on deposition behavior of HVOF particles. Surf Technol:1–13. https://doi.org/10.16490/j.cnki.issn.1001-3660.2020.11.012

Acharya S, Dash SK (2021) Natural convection heat transfer from a vertical hollow cylinder with surface holes. ASME J Heat Transfer 143(4). https://doi.org/10.1115/1.4049840

Singh TP, Kumar A, Satapathy AK (2021) Role of a sinusoidal wavy surface in enhancement of heat transfer using turbulent dual jet. ASME J Heat Transfer 143(3). https://doi.org/10.1115/1.4049274

ANSYS (2011) Fluent Documentation

Singh P, Ratna Kishore V, Chander S (2020) Computational fluid dynamics analysis of aerodynamics and impingement heat transfer from hexagonal arrays of multiple dual-swirling impinging flame jets. ASME J Heat Transfer 142(8):1–15. https://doi.org/10.1115/1.4047055

Fan W, Zhong F (2021) Numerical study of turbulent convective heat transfer of aviation kerosene in coiled pipes. ASME J Heat Transfer. https://doi.org/10.1115/1.4050410

Jiang HR, Li ML, Wei XS et al (2019) Numerical investigation of in-flight behavior of Fe-based amorphous alloy particles in AC-HVAF thermal spray process. J Therm Spray Technol 28(6):1146–1159. https://doi.org/10.1007/s11666-019-00889-7

Gordon S, McBride BJ (1994) Computer program for calculation of complex chemical equilibrium compositions and applications. Part 1: analysis. NASA

Cheng D, Xu Q, Lavernia EJ et al (2001) The effect of particle size and morphology on the in-flight behavior of particles during high-velocity oxyfuel thermal spraying. Metall Mater Trans B 32(3):525–535. https://doi.org/10.1007/s11663-001-0037-3

Zhou Z, Chen Y, Hu Z et al (2020) Numerical investigation of particles in warm-particle peening-assisted high-velocity oxygen fuel (WPPA-HVOF) spraying. J Therm Spray Technol (29):1682–1694. https://doi.org/10.1007/s11666-020-01063-0

Xiong HB, Zheng LL, Sampath S et al (2004) Three-dimensional simulation of plasma spray: effects of carrier gas flow and particle injection on plasma jet and entrained particle behavior. Int J Heat Mass Tran 47(24):5189–5200. https://doi.org/10.1016/j.ijheatmasstransfer.2004.07.005

Ranz WE, Marshall WR (1952) Evaporation from drops. Chem Eng Prog 48(173):141–146

Baik JS, Kim YJ (2008) Effect of nozzle shape on the performance of high velocity oxygen-fuel thermal spray system. Surf Coat Technol 202(22–23):5457–5462. https://doi.org/10.1016/j.surfcoat.2008.06.061

Funding

This work was supported by the Open topics of firefighting key laboratories of the Ministry of Public Security (Grant No. KF201704), Innovation Team Building Project of the University of Science and Technology Liaoning (601009830–02), Liaoning Province Natural Science Foundation Guidance Project in Liaoning Province, and the Key R&D Plan Science and Technology Support Project in Tianjin City (S20ZC771198), Liaoning Province Higher Education Innovative Talent Support Program (20201005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission I—Additive Manufacturing, Surfacing, and Thermal Cutting

Rights and permissions

About this article

Cite this article

Han, X., Li, C., Gao, X. et al. Numerical study on the behavior of titanium particles in the process of warm spraying. Weld World 66, 1305–1314 (2022). https://doi.org/10.1007/s40194-022-01292-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01292-7