Abstract

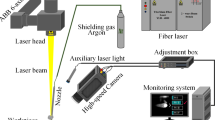

In an automatic tungsten inert gas welding process of thin plates with a reserved gap, weld pool shape and fusion hole size are closely related to the weld quality. A vision-based weld area monitoring system is designed to simultaneously monitor the fusion hole from the front and back of the workpiece. Considering the location of fusion hole is not stable, an improved target detection network (YOLOV3) was proposed to localize the fusion hole. And ResNet-d is used as the backbone network in this model. The optimized YOLOv3 achieves an accuracy of 95.03% on mAP50 and a prediction speed of 49.43 frames per second (FPS). A corresponding image processing algorithm is designed based on the regional growth method, which can obtain clear edges and the width of the fusion hole. The algorithm’s accuracy is verified by compared with the extracted fusion hole widths from simultaneous images obtained from the backside.

Similar content being viewed by others

References

Wang H, Kovacevic R (2002) On-line monitoring of the keyhole welding pool in variable polarity plasma arc welding. Proceeding Inst Mech Eng Part B J Eng Manuf 216:1265–1276

Cui Y-X, Shi Y-H, Ning Q et al (2021) Investigation into keyhole-weld pool dynamic behaviors based on HDR vision sensing of real-time K-TIG welding process through a steel/glass sandwich. Adv Manuf 9:136–144. https://doi.org/10.1007/s40436-020-00335-w

Guo Y, Gao J, Wu CS, Gui X (2019) Correlation between fusion hole morphology and weld penetration in TIG welding. Int J Adv Manuf Technol 101. https://doi.org/10.1007/s00170-018-3063-x

Li C, Gao J, Cao Y et al (2019) Visual observation of fusion hole in thin plate TIG welding with a reserved gap. J Manuf Process 45:634–641. https://doi.org/10.1016/j.jmapro.2019.08.002

Cao Y, Wang X, Yan X et al (2020) Prediction of fusion hole perforation based on arc characteristics of front image in backing welding. Materials 13:4706. https://doi.org/10.3390/ma13214706

Luo M, Shin Y (2015) Estimation of keyhole geometry and prediction of welding defects during laser welding based on a vision system and a radial basis function neural network. Int J Adv Manuf Technol 81. https://doi.org/10.1007/s00170-015-7079-1

Knaak C, Kröger M, Schulze F, et al (2021) Deep Learning and conventional machine learning for image-based in-situ fault detection during laser welding: a comparative study. https://doi.org/10.20944/preprints202105.0272.v1

Xia C, Pan Z, Fei Z et al (2020) Vision based defects detection for keyhole TIG welding using deep learning with visual explanation. J Manuf Process 56:845–855. https://doi.org/10.1016/j.jmapro.2020.05.033

Wu D, Huang Y, Zhang P et al (2020) Visual-Acoustic penetration recognition in variable polarity plasma arc welding process using hybrid deep learning approach. IEEE Access 8:120417–120428. https://doi.org/10.1109/ACCESS.2020.3005822

Wang Y, Han J, Lu J et al (2020) TIG stainless steel molten pool contour detection and weld width prediction based on Res-Seg. Metals 10:1495. https://doi.org/10.3390/met10111495

Yang L, Fan J, Liu Y et al (2021) Automatic detection and location of weld beads with deep convolutional neural networks. IEEE Trans Instrum Meas 70:1–12. https://doi.org/10.1109/TIM.2020.3026514

Tianjiao L, Hong B (2020) A optimized YOLO method for object detection. In: 2020 16th International Conference on Computational Intelligence and Security (CIS). pp 30–34

Kim H, Nam K, Oh S, Ki H (2021) Deep-learning-based real-time monitoring of full-penetration laser keyhole welding by using the synchronized coaxial observation method. J Manuf Process 68:1018–1030. https://doi.org/10.1016/j.jmapro.2021.06.029

Girshick R (2015) Fast R-CNN. ArXiv E-Prints arXiv:1504.08083

Ren S, He K, Girshick R, Sun J (2017) Faster R-CNN: towards real-time object detection with region proposal networks. IEEE Trans Pattern Anal Mach Intell 39:1137–1149. https://doi.org/10.1109/TPAMI.2016.2577031

Liu W, Anguelov D, Erhan D, et al (2016) SSD: Single Shot multibox detector. Comput Vis – ECCV 2016 21–37. https://doi.org/10.1007/978-3-319-46448-0_2

Redmon J, Divvala S, Girshick R, Farhadi A (2016) You only look once: Unified, real-time object detection. In: Proceedings of the IEEE conference on computer vision and pattern recognition. pp 779–788

Simonyan K, Zisserman A (2015) Very Deep convolutional networks for large-scale image recognition. arXiv:1409.1556. https://arxiv.org/abs/1409.1556

Szegedy C, Vanhoucke V, Ioffe S, et al (2016) Rethinking the inception architecture for computer vision. 2818–2826. https://doi.org/10.1109/CVPR.2016.308

He K, Zhang X, Ren S, Sun J (2015) Deep residual learning for image recognition. ArXiv E-Prints arXiv:1512.03385

Jie H, Li S, Gang S, Albanie S (2020) Squeeze-and-excitation networks. IEEE Transactions on Pattern Analysis and Machine Intelligence 42(8):2011–2023. https://doi.org/10.1109/TPAMI.2019.2913372

Howard AG, Zhu M, Chen B, et al (2017) MobileNets: Efficient convolutional neural networks for mobile vision Applications. ArXiv170404861 Cs

Redmon J, Farhadi A (2018) YOLOv3: An Incremental improvement. CoRR abs/1804.02767. http://arxiv.org/abs/1804.02767

Lin T-Y, Dollár P, Girshick R et al (2017) Feature Pyramid networks for object detection. IEEE Conf Comput Vis Pattern Recognit CVPR 2017:936–944. https://doi.org/10.1109/CVPR.2017.106

Liu Y, Sun X, Pang JHL (2020) A YOLOv3-based deep learning application research for condition monitoring of rail thermite welded joints. Proc 2020 2nd Int Conf Image Video Signal Process 33–38. https://doi.org/10.1145/3388818.3388827

Liu M, Xie J, Hao J et al (2022) A lightweight and accurate recognition framework for signs of X-ray weld images. Comput Ind 135:103559. https://doi.org/10.1016/j.compind.2021.103559

Zhang X, Wang C, Xiang C, et al (2021) Intelligent Detection method for welding seam defects of automobile wheel hub based on YOLO. Adv Manuf Autom X 693–702. https://doi.org/10.1007/978-981-33-6318-2_86

He T, Zhang Z, Zhang H, Zhang Z, Xie J, Li M (2018) Bag of tricks for image classification with convolutional neural networks. CoRR abs/1812.01187. http://arxiv.org/abs/1812.01187

Liu S, Qi L, Qin H et al (2018) Path Aggregation network for instance segmentation. IEEECVF Conf Comput Vis Pattern Recognit 2018:8759–8768. https://doi.org/10.1109/CVPR.2018.00913

Redmon J, Farhadi A (2017) YOLO9000: better, faster, stronger. IEEE Conf Comput Vis Pattern Recognit CVPR 2017:6517–6525. https://doi.org/10.1109/CVPR.2017.690

Huang G, Liu Z, Van Der Maaten L, Weinberger KQ (2017) Densely connected convolutional networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition. pp 4700–4708

Rezatofighi H, Tsoi N, Gwak J et al (2019) Generalized intersection over union: a metric and a loss for bounding box regression. IEEECVF Conf Comput Vis Pattern Recognit CVPR 2019:658–666. https://doi.org/10.1109/CVPR.2019.00075

Ge R, Huang F, Jin C, Yuan Y (2015) Escaping From saddle points --- online stochastic gradient for tensor decomposition. CoRR abs/1503.02101. http://arxiv.org/abs/1503.02101

Dai W, Li D, Tang D et al (2021) Deep learning assisted vision inspection of resistance spot welds. J Manuf Process 62:262–274

Ioffe S, Szegedy C (2015) Batch Normalization: accelerating deep network training by reducing internal covariate shift. ArXiv E-Prints arXiv:1502.03167

Ma N, Zhang X, Zheng HT, Sun J (2018) ShuffleNet V2: Practical guidelines for efficient CNN Architecture design. In: European Conference on Computer Vision

Huang X, Wang X, Lv W, Bai X, Long X, Deng K, Dang Q, Han S, Liu Q, Hu X, Yu D, Ma Y, Yoshie O (2021) PP-YOLOv2: A practical object detector. CoRR abs/2104.10419. https://arxiv.org/abs/2104.10419

Lin T-Y, Maire M, Belongie S, et al (2014) Microsoft COCO: common objects in context. Comput Vis – ECCV 2014 740–755. https://doi.org/10.1007/978-3-319-10602-1_48

Everingham M, Van Gool L, Williams CKI et al (2010) The Pascal visual object classes (VOC) challenge. Int J Comput Vis 88:303–338. https://doi.org/10.1007/s11263-009-0275-4

Yun S, Han D, Oh SJ, et al (2019) CutMix: Regularization strategy to train strong classifiers with localizable features. ArXiv E-Prints arXiv:1905.04899

Misra D (2020) Mish: a self regularized non-monotonic activation function. ArXiv190808681 Cs Stat

Woo S, Park J, Lee J-Y, Kweon IS (2018) Cbam: convolutional block attention module. Proc Eur Conf Comput Vis ECCV 3–19. http://link.springer.com/10.1007/978-3-030-01234-2_1

Zuiderveld K (1994) Contrast limited adaptive histogram equalization. Graph Gems IV 474–485. https://doi.org/10.1016/B978-0-12-336156-1.50061-6

Pong T-C, Shapiro LG, Watson LT, Haralick RM (1984) Experiments in segmentation using a facet model region grower. Comput Vis Graph Image Process 25:1–23. https://doi.org/10.1016/0734-189X(84)90046-X

Loshchilov I, Hutter F (2016) SGDR: Stochastic Gradient Descent With Warm Restarts. CoRR abs/1608.03983. http://arxiv.org/abs/1608.03983

Olague G, Hernández DE, Llamas P et al (2019) Brain programming as a new strategy to create visual routines for object tracking. Multimed Tools Appl 78:5881–5918. https://doi.org/10.1007/s11042-018-6634-9

Dalal N, Triggs B (2005) Histograms of oriented gradients for human detection. In: 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’05). IEEE, San Diego, CA, USA, pp 886–893

Platt J (1998) Sequential minimal optimization: a fast algorithm for training support vector machines. Adv Kernel Methods-Support Vector Learn 208. https://www.microsoft.com/en-us/research/publication/sequential-minimal-optimization-a-fast-algorithm-for-training-support-vector-machines/

Funding

This work was supported by National Natural Science Foundation of China (No. 51675309).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Ethical approval was not required for this study.

Consent to participate

Written informed consent was obtained from individual or guardian participants.

Consent to publish

The manuscript was approved by all authors for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XII - Arc Welding Processes and Production Systems

Rights and permissions

About this article

Cite this article

Li, S., Gao, J., Zhou, E. et al. Deep learning-based fusion hole state recognition and width extraction for thin plate TIG welding. Weld World 66, 1329–1347 (2022). https://doi.org/10.1007/s40194-022-01287-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01287-4