Abstract

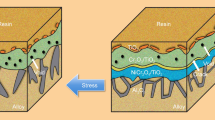

To explore the potential significance of high entropy alloys for the joining of extremely dissimilar materials, a NiCoFeCuSiB high entropy alloy was newly designed and used as filler metal to braze TiAl-based alloy and a deformed Ni-based superalloy. The microstructures at the joining interfaces were investigated. The as-cast NiCoFeCuSiB high entropy filler alloy was mainly composed of (Co,Fe,Ni) solid solution and (Ni,Co,Fe,Cu,Si) multi-element complex phase. The wettability experiment results indicated that a lower contact angle and better spreading behavior was obtained on the Ni-based superalloy than TiAl-based alloy at 1120 °C/10 min. At the interface of Ni-based superalloy/NiCoFeCuSiB filler, (Ni,Fe,Cr,Co,Cu,Ti,Al) multi-element complex phase was formed and sound metallurgical bonding was achieved. For the interface close to TiAl-based alloy, the diffusion affect zone consisted of γ-TiAl and γ-TiAl(Cu,Ni) phases was visible. The brazed seam was mainly composed of (Ni,Al,Ti,Fe,Co), (Ni,Al,Ti,Co,Fe,Cu), and (Ni,Fe,Cr,Co,Cu,Ti,Al) multi-element complex phases.

Similar content being viewed by others

References

Kartavykh AV, Asnis EA, Piskun NV, Statkevich II, Gorshenkov MV, Korotitskiy AV (2017) Room-temperature tensile properties of float-zone processed stabilized γ-TiAl(Nb, Cr, Zr) intermetallic. Mater Lett 188:88–91

Perrut M, Caron P, Thomas M, Couret A (2018) High temperature materials for aerospace applications: Ni-based superalloys and γ-TiAl alloys. C R Phys 19:657–671

Clemens H, Smarsly W (2011) Light-weight intermetallic titanium aluminides-status of research and development. Adv Mater Res 278:551–556

Bewlay BP, Nag S, Suzuki A, Weimer MJ (2016) TiAl alloys in commercial aircraft engines. Mater High Temp 33(549–559):4

Sequeiros EW, Guedes A, Pinto AMP, Vieira MF, Viana F (2013) Microstructure and strength of γ-TiAl alloy/Inconel 718 brazed joints. Mater Sci Forum 730–732:835–840

Ren HS, Xiong HP, Long WM, Shen YX, Pang SJ, Chen B, Cheng YY (2018) Interfacial diffusion reactions and mechanical properties of Ti3Al/Ni-based superalloy joints brazed with AgCuPd filler metal. Mater Charact 144:316–324

Ren HS, Xiong HP, Ye L, Ren XY, Li WW, Qin RY (2021) Microstructures and mechanical properties of TiAl/Ni-based superalloy joints brazed with Fe-based filler metal. Weld World 65:79–85

Alshataif YA, Sivasankaran S, Al-Mufadi FA, Alaboodi AS, Ammar HR (2020) Manufacturing methods, microstructural and mechanical properties evolutions of high entropy alloys: a review. Met Mater Int 26:1099–1133

Kokabi D, Kaflou A (2021) TiAl/IN718 dissimilar brazing with TiZrNiCuCo high-entropy filler metal: phase characterization and fractography. Weld World 65:1189–1198

Gao MR, Schneiderman B, Gilbert SM, Yu ZZ (2019) Microstructural evolution and mechanical properties of nickel-base superalloy brazed joints using a MPCA filler. Metall Mater Trans A 50:5117–5127

Bridges D, Zhang SH, Lang S, Gao MR, Yu ZZ, Feng ZL, Hu AM (2018) Laser brazing of a nickel-based superalloy using a Ni-Mn-Fe-Co-Cu high entropy alloy filler metal. Mater Lett 215:11–14

Li P, Wang S, Xia YQ, Hao XH, Dong HG (2020) Diffusion bonding of AlCoCrFeNi2.1 eutectic high entropy alloy to TiAl alloy. J Mater Sci Technol 45:59–69

Tillmann W, Wojarski L, Stangier D, Manka M, Timmer C (2020) Application of the eutectic high entropy alloy Nb0.73CoCrFeNi2.1 for high temperature joints. Weld World 64:1597–1604

Massalski TB (1986) Binary Alloy Phase Diagrams, ASM, Metals Park, OH, pp. 366–371

Miedema AR, Boer FRDE, Boom R, Dorleijn JWF (1977) Model predictions for the enthalpy of formation of transition metal alloys. Calphad 1:341–359

Tillmann W, Ulitzka T, Wojarski L, Manka M, Ulitzka H, Wagstyl D (2020) Development of high entropy alloys for brazing applications. Weld World 64:201–208

Ren HS, Ren XY, Long WM, Chen B, Pang SJ, Xiong HP (2021) Formation mechanism ofinterfacial microstructure and mechanical properties of Ti2AlNb/Ni-basedsuperalloy joint brazed with NiCrFeSiB filler metal. Prog Nat Sci-Mater 31:296–304

Li N, Liu W, Wang Y, Zhao ZJ, Yan TQ, Zhang GH, Xiong HP (2021) Laser additive manufacturing on metal matrix composited: A review. Chin J Mech Eng-En 34:38

Li N, Huang S, Zhang GH, Qin RY, Liu W, XiongHP Shi GQ, Blackburn J (2019) Progress in additive manufacturing on newmaterials: A review. J Mater Sci Technol 35:242–269

Funding

This research work was sponsored by the National Natural Science Foundation of China (No. 51705489, No. 51671008).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Ren, H.S., Feng, H.L., Ren, X.Y. et al. Joining of TiAl-based alloy and a Ni-based superalloy with a NiCoFeCuSiB high entropy filler metal. Weld World 66, 557–565 (2022). https://doi.org/10.1007/s40194-021-01245-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01245-6